Automatic Syringe Labeling Machine

Syringe labeling systems, tailored for pharmaceutical syringes to ensure accurate labeling and compliance with packaging standards.

√ Tailored for any syringe size

√ Efficient for high-volume labeling

√ Accuracy up to ±1mm

√ Fast turnaround and support

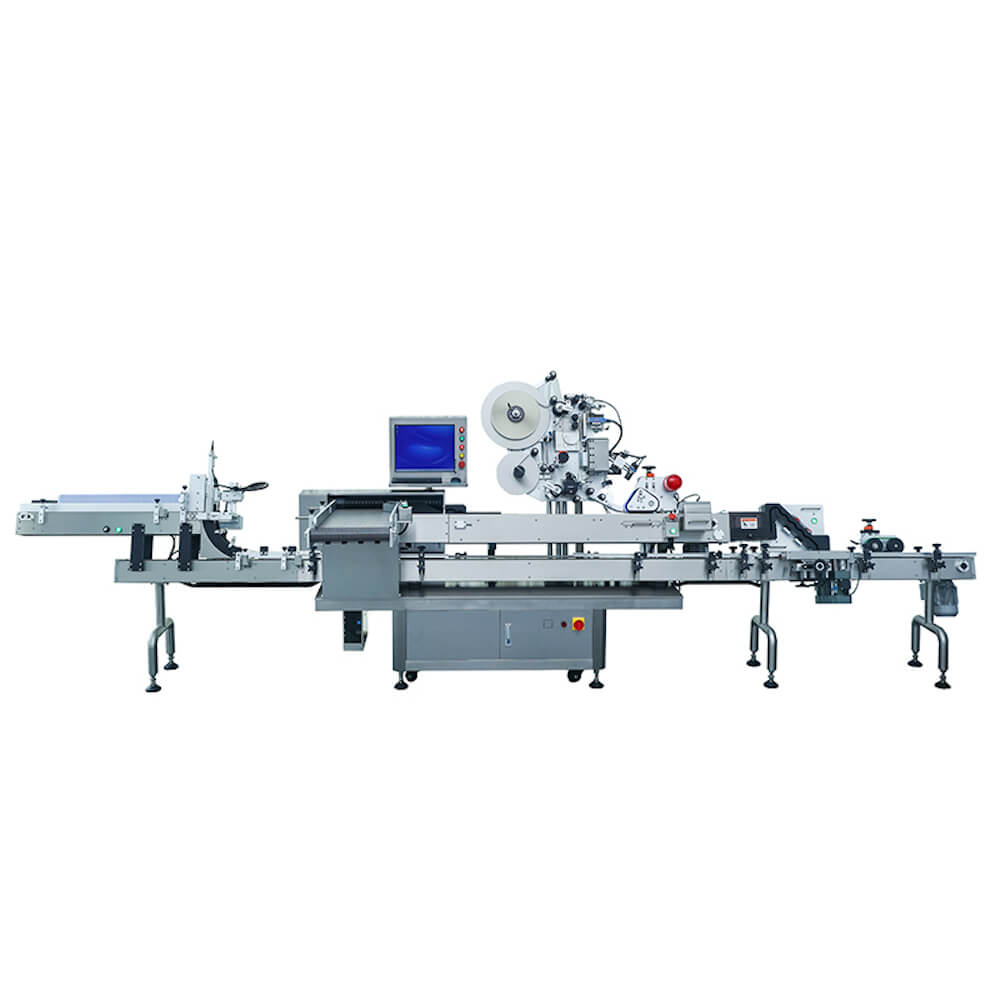

Full automatic horizontal syringe labeling machine

- Labeling speed: 0-500 bottles/minLabeling accuracy:±1mmApplicable bottle diameter: Φ10mm~Φ30mm SyringesApplication

Designed specifically for the pharma industry, it is perfect for labeling small cylindrical containers such as pharmacy syringes, auto injection devices…

The wrap-around labeling machine offers consistent quality and efficiency with a remarkably low product and label breakage rate, below 0.01% and 0.1% respectively, and the lable pass rate of over 99.9%. This performance is essential for meeting the rigorous packaging demands of pharmaceutical manufacturing.

- Various label material compatibility including paper and transparent labels

- Label rolls specifications tailored for diverse labeling requirements

- Customizable features to meet specific operational needs.

-

Suitable for paper and transparent labels

-

Label length range: 25mm to 95mm

-

Power requirements: 2.5KW, AC220V, 50HZ

-

The labeler weight: Approximately 380Kg

-

Noise level: Less than 75dB

-

Compatible with label rolls having an inner diameter of φ76mm and an outer diameter of up to Φ300mm.

-

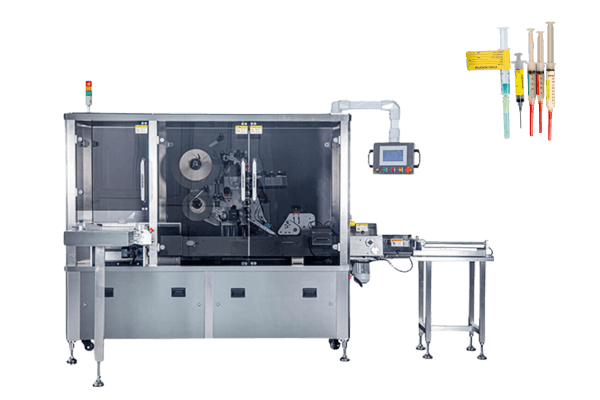

Automated labeling machine for syringe with protection cover

Labeling speed: 0-500 pcs/min

labeling accuracy:±1mm

Applicable product diameter (for small containers): Φ10mm~Φ30mm syringesApplicationHorizontal labeling, designed for labeling syringes and a series of pharmaceutical containers that cannot stand.

The machine combines high functionality with user safety and is equipped with a protective cover to ensure safe operation.

- Protective cover for enhanced safety

- High-efficiency labeling applicator and motor

- Customizable features based on client needs.

-

Suitable for paper and transparent labels

-

Label length range: 25mm to 95mm

-

Power requirements: 2.5KW, AC220V, 50HZ

-

The labeler weight: Approximately 380Kg

-

Noise level: Less than 75dB

-

Compatible with label rolls having an inner diameter of φ76mm and an outer diameter of up to Φ300mm.

-

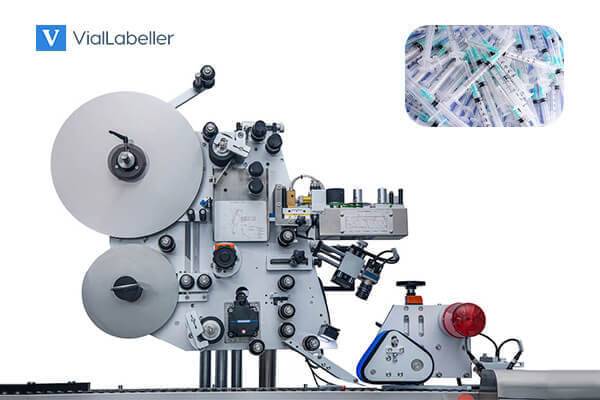

Automatic syringe labeling machine with tray inserting

- Labeling speed: 0-500 pcs/minlabeling accuracy:±1mmApplicable product diameter: Φ10mm~Φ30mm syringesApplication

The Y-510 automatic wrap-around labler machine, designed for syringes from 1-20ml, features an advanced tray inserting system and labeling capabilities, handling trays of 50-150mm in length and 60-120mm in width. It places 5 or 10 syringes per tray, achieving a rate of 30 to 90 trays per minute.

It utilizes a specialized splitting mechanism for stacking plastic trays, ensuring fast, damage-free separation without overlaps. Horizontal feedingenhances ease and efficiency, with a low breakage rate.

Integrate with servo motors for quick, precise labeling, with an error margin of ±0.5mm, and utilizes a unique S-shaped track design for gentle handling, minimizing label damage and ensuring smooth operation.

- Advanced tray handling system

- High-speed labeling applicator

- Custom configurations based on operational requirements

- Supports paper and transparent label materials

-

Label length: 25mm to 95mm

-

Power requirements: 2.5KW, AC220V, 50HZ

-

Machine weight: Approximately 380Kg

-

Noise level: Below 75dB

-

Compatible with label rolls having an inner diameter of φ76mm and an outer diameter of up to Φ300mm.

-

What is a syringe labeling machine?

Labeling syringes can identify the basic information about drugs for medical personnel and facilitate the traceability management of the medical system, so the use of syringe labeling machines has become a necessary part of the production of medical devices.

Syringe labeling machines are specialized in applying pressure-sensitive labels to syringes(with or without liquid) and can handle a wide range of syringe sizes and labels, ensuring accurate labeling and meeting strict hygiene standards.

Why choose syringe labeler at Viallabeller

We offer a series of pressure-sensitive labeling systems tailored to meet the diverse needs of the pharma packaging industry. Our machines are designed for versatility, capable of handling a wide range of product sizes.

Our syringe labeling systems stand out for their extremely low product and label breakage rates, alongside a labeling pass rate exceeding 99.9%, guaranteeing operational reliability.

They accommodate a variety of label materials, including paper and transparent labels, offering flexibility to meet syringe labeling requirements. Built with high-quality materials and advanced manufacturing processes, our machines ensure stability, reliability, and reduced maintenance costs.

Starting from your initial inquiry to post-delivery support, Viallabeller is committed to providing a seamless and supportive experience. Receive a free, customized quotation, witness the meticulous production process, and benefit from our comprehensive after-sales support, including on-site engineer guidance.

Choose our labeling systems for bulk syringe solutions that blend speed, precision, and reliability, ensuring any types of pharmaceutical packaging needs are met with excellence.

Custom syringe labeling machine service

We offer a series of industrial syringe labeling machines specifically designed for pharmaceutical manufacturing. As a leading labeling machine manufacturer, we ensure you get the perfect machine for your needs. Here’s our customized process:

Talk and plan: We chat with you to understand what you need. We use your ideas to sketch out a machine that does exactly what you want.

Build: Once we agree on the design, we start putting it together using the best parts.

Test and check: You get to see your machine work at our place. This is when you can say if it’s perfect or needs a little tweak.

Set up and support: We help set it up at your place and make sure everything runs smoothly. We also help with any paperwork needed to get started.

Leave a message now to get the perfect syringe labeling machine for your production line.

Syringe labeling labeler FAQs

- How does the syringe labeling machine work?

The machine automatically applies labels to syringes using precise mechanical placement and adhesive technology.

- What’s the difference between manual and machine labeling for syringes?

Machine labeling offers faster, more consistent application than manual, improving efficiency and accuracy.

- Is it possible to get a design drawing tailored to our factory setup?

Absolutely, one of our engineers will prepare a complimentary design for your review before we finalize the quote.

- Do you provide training on how to operate and maintain the machine?

Indeed, we offer complimentary online training sessions on the operation and maintenance of our machines to ensure our clients can operate and upkeep their machines efficiently.

- What’s the expected time frame to receive a machine once an order is placed?

The delivery period can vary based on the machine type and our current production line-up, but it generally ranges from 6 to 8 weeks.

- Which payment methods do you support?

We offer several payment options, including bank transfers, credit cards, and PayPal, for your convenience.

- How long does it take to receive a machine after ordering?

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

- What kind of support do you provide after a machine is purchased?

For the entire lifespan of your machine, we provide online assistance for technical issues and troubleshooting, in addition to supplying parts and servicing support.

- What’s the warranty term for your machines?

All our machines come with a standard 1-year warranty, with the option to request extended warranties.

More labeling solutions for pharmaceutical products

Vial labeling

Labeling vials is also a headache problem for pharmaceutical manufacturers.

Ampoule labeling

Labeling ampoules presents unique challenges in the pharmaceutical industry.

Tamper evident labeling

Labeling tamper-evident seals provides a method for security-conscious brands.

Let’s work together

We’d love to hear from you! Send us a message using the form opposite, or email us. We’d love to hear from you! Send us a message using the form below.