Syringe sizes vary, and they have been a staple in medical practice for decades. Different syringe sizes are available to meet various medical needs. Plastic syringes are predominant in medical settings due to their disposability and cost-effectiveness.

Commonly seen in hospitals, these tools are essential for delivering medications directly to hard-to-reach areas, not only in humans but also in animals. Their widespread use reflects their critical role in both healthcare and veterinary services.

Syringe barrel sizes and syringe tip types

Syringes are designed in a variety of types to suit specific medical needs, differentiated by features such as capacity, syringe tips, needle sizes, and needle gauges. we will focuses exclusively on the various syringe types categorized by their barrel sizes and the importance of selecting the right syringe and needle size, including different size syringes.

Understanding the different barrel sizes is crucial for selecting the appropriate syringe for a given medical application, ensuring accurate dosage and effective delivery of medication. This classification helps streamline the selection process for medical professionals, enhancing both safety and efficiency in patient care.

Understanding syringe barrel capacities

Determining the correct syringe size is crucial for accurately administering medication dosages. It is essential to match the syringe’s capacity with the volume of the drug being administered. The selection of the right needle size is influenced by factors such as the medication being administered and the patient’s body size. For subcutaneous injections, it is important to use shorter and thinner needles, typically with a smaller gauge, to ensure accurate and safe administration.

For administering larger volumes of medication, larger capacity syringes should be selected to accommodate the dosage while maintaining appropriate pressure flow. Smaller syringes offer higher pressure flow, which is suitable for smaller dosages.

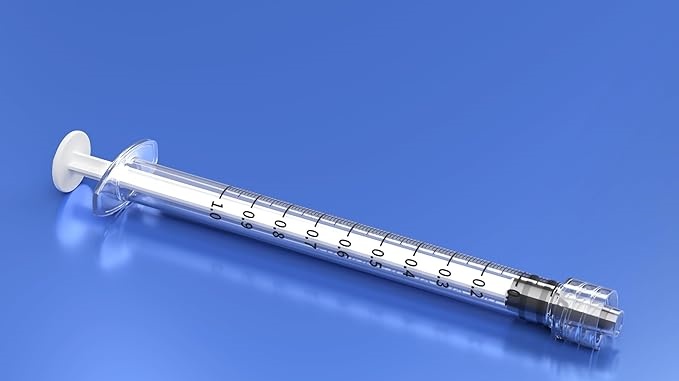

Syringe sizes are defined by their capacity to hold liquids and are typically measured in milliliters (mL) and cubic centimeters (cc), where one cc is approximately equal to one mL. This standardization aids in precise dosage measurements.

Syringes feature milliliter (mL) markings on their barrels to help users accurately gauge the amount of medication being administered. It’s also critical to ensure that the plunger’s top ring is precisely measured to ensure the correct dosage is drawn and delivered.

1 ml insulin syringes

One milliliter (1 mL) syringes, equivalent to one cubic centimeter (1 cc), are predominantly used in medical settings for precise dosage applications. These syringes are also commonly used as insulin syringes, which are specifically designed for self-injection and calibrated in insulin units. The various sizes and gauges of insulin needles can significantly impact comfort during injections and the effectiveness of insulin delivery, making it essential to select appropriate lengths and thicknesses to avoid complications and enhance user experience. These syringes are ideal for diabetic and tuberculin medications, along with intradermal injections, where dosage accuracy is critical.

Tuberculin syringes typically feature needles longer than half an inch, with a gauge between 26G and 27G. For intradermal injections, 1 mL syringes can be employed with needle gauges ranging from 25G to 26 G.

These syringes facilitate the administration of small, precise doses required in various medical scenarios, such as allergy testing and insulin administration, ensuring minimal discomfort and effective delivery of medication to the patient. The choice of needle gauge and length is crucial to match the specific medical requirements and patient needs, enhancing both the efficacy and safety of treatments.

2 ml to 3 ml syringes

Syringes with capacities ranging from 2 mL to 3 mL are commonly utilized for administering vaccines. Selecting the appropriate syringe size is critical and should align with the specific vaccine dose required. Additionally, choosing the correct needle is essential, considering factors such as the type of vaccine and the patient’s body size. Using thinner needles can provide a more comfortable injection experience and improve the efficacy of vaccine delivery.

Typically, the needle gauges used for these vaccine injections range between 23G and 25 G. The length of the needle varies depending on factors such as the patient’s age and the specific injection site, which are essential for minimizing the risk of injection site reactions.

Choosing the right needle length is crucial for ensuring effective vaccine delivery and avoiding complications. These syringes enable healthcare providers to administer vaccines safely and efficiently, contributing to public health and individual well-being.

The adaptability of these syringes to different patient needs makes them a vital tool in medical practices, especially in pediatric and adult immunization programs.

5 ml syringes

Syringes with a capacity of 5 mL are specifically designed to measure and deliver doses of liquid medication accurately, up to 5 ccs. These syringes are predominantly used for intramuscular injections, which are administered directly into muscle tissue. A lower gauge needle, while potentially more painful, is preferable for administering thicker medications in intramuscular injections.

For optimal delivery, intramuscular injections should be given at a precise 90-degree angle to ensure the medication is properly absorbed by the muscle. The recommended gauge size for the needles used with these syringes ranges between 22G and 23 G.

This syringe type is essential for a wide range of medical applications, including vaccinations and therapeutic injections, providing a reliable method for effective drug delivery.

The design and capacity of 5 mL syringes make them suitable for treatments requiring larger volumes of medication, ensuring both patient comfort and effective absorption of the drug into the bloodstream.

10 ml syringes

The 10 mL syringes are specifically designed for large-volume intramuscular injections, accommodating higher doses of medication necessary for certain treatments. These syringes allow for the administration of substantial quantities of medication directly into the muscle, enhancing the absorption and effectiveness of the drug.

Selecting the correct gauge needle is crucial for minimizing discomfort while ensuring efficient medication delivery.

The ideal needle length for such injections is typically between 1 and 1.5 inches for adults, ensuring deep muscle penetration without impacting surrounding tissues. The recommended needle gauge for these procedures is between 22G and 23G, which helps in minimizing discomfort while ensuring efficient medication delivery.

These syringes are indispensable in settings that require significant medication doses, such as in the treatment of chronic diseases or in emergency medical interventions.

20 ml syringes

The 20 ml syringes are distinguished by their larger capacity, making them particularly suitable for mixing and administering combinations of medications. These syringes can be equipped with a catheter tip, which is longer and tapered, allowing for a tighter seal when inserted into various openings. These syringes facilitate the process of combining multiple drugs within a single syringe, which can then be connected to an infusion set for intravenous delivery to the patient.

This capability is essential in clinical settings where precise dosages of compounded medications are necessary for effective treatment protocols.

The larger volume of 20 mL syringes ensures that they can accommodate more substantial amounts of medication, reducing the need for multiple syringes and simplifying the administration process.

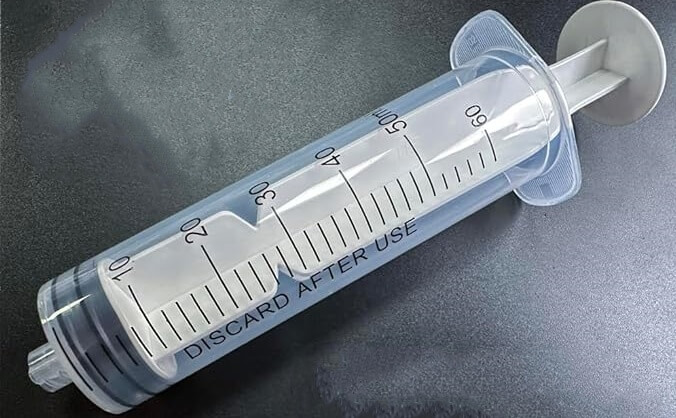

50 – 60 ml syringes

The 50 – 60 mL syringes, with their substantial capacity, are primarily utilized in conjunction with scalp vein sets for intravenous injections. This size allows for the administration of large volumes of fluid directly into the bloodstream, suitable for treatments requiring rapid and significant medication delivery.

A variety of scalp vein sets can be paired with these syringes, ranging from 18G to 27G, depending on the diameter of the patient’s vein and the viscosity of the solution being administered. Selecting the appropriate needle gauge size is crucial for ensuring effective and safe intravenous injections.

These larger syringes are essential in medical settings where high-volume infusions are necessary, such as during fluid resuscitation, electrolyte balancing, or administering blood products.

Their use ensures efficient and effective delivery of therapeutic substances, supporting critical care and emergency medical interventions where timing and dosage can be life-saving.

Importance of syringe and needle gauge labeling

Accurate labeling of syringe sizes is critical for ensuring the safety and effectiveness of medical treatments. Oral syringes, which are designed for administering liquid medications directly into the mouth, also require accurate labeling to ensure proper use. Proper labeling helps healthcare professionals quickly identify the right syringe for specific medical applications, reducing errors and enhancing patient care.

Our advanced syringe labeling machines provide reliable, precise, and efficient labeling solutions for syringes, supporting healthcare facilities in maintaining high standards of practice and compliance with regulatory requirements.

We not only have solutions for syringe labeling for any sizes of syringes, but other medical device labeling solutions are also available, the following are medical devices that our company can label: