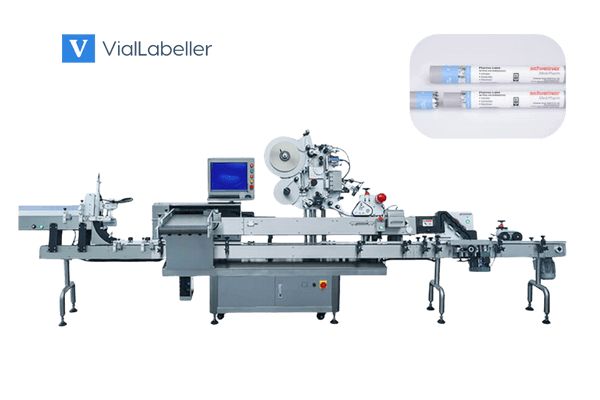

Viallabeller’s Auto-Injection Pen Solution

Our labeling solution for auto injections guarantees precise labeling and follows all the rules for packaging medicine. Start your custom labeling process now.

√ Adaptable for almost auto injection devices

√ High-Volume Labeling Efficiency

√ Precision up to ±1mm

√ Quick turnaround and Comprehensive Support

VialLabeller has been specializing in providing high-precision labeling solutions for the pharmaceutical industry for many years. Our systems easily handle various shapes and sizes of injection pens and auto-injectors, including round, conical, and triangular designs, ensuring accurate and reliable labeling.

Whether operating offline or online, our solutions can efficiently process up to 500 products per minute. This ensures that each automatic injection device is accurately labeled, clearly displaying key information such as dosage instructions, expiration dates, and product identification, thereby ensuring patient safety and correct medication use.

Accurately applies labels to various shapes and sizes of auto-injection devices, meeting the highest industry standards.

Labels up to 500 products per minute, supporting serialization and traceability with high productivity.

Easily handles different product requirements while ensuring compliance with FDA and GMP regulations.

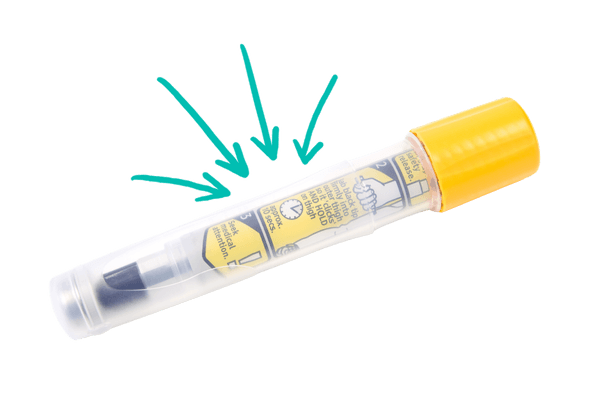

These Solutions are Used for Your Injection Devices

We offer specialized horizontal labeling solutions, which are perfect for handling auto-injection devices like auto pens and insulin injectors. This method ensures that labels are applied smoothly and accurately across the entire surface of the product.

Our solutions not only adapt to different shapes and sizes of injection pens, but also meet the complex requirements for drug serialization and traceability. This ensures that every device is labeled with high precision(less than 0.01% product breakage and over 99.9% labeling accuracy) according to strict pharmaceutical standards like FDA and GMP.

Explore our automatic sticker labeling systems for efficiently and accurately handle the specific needs of auto-injection devices below:

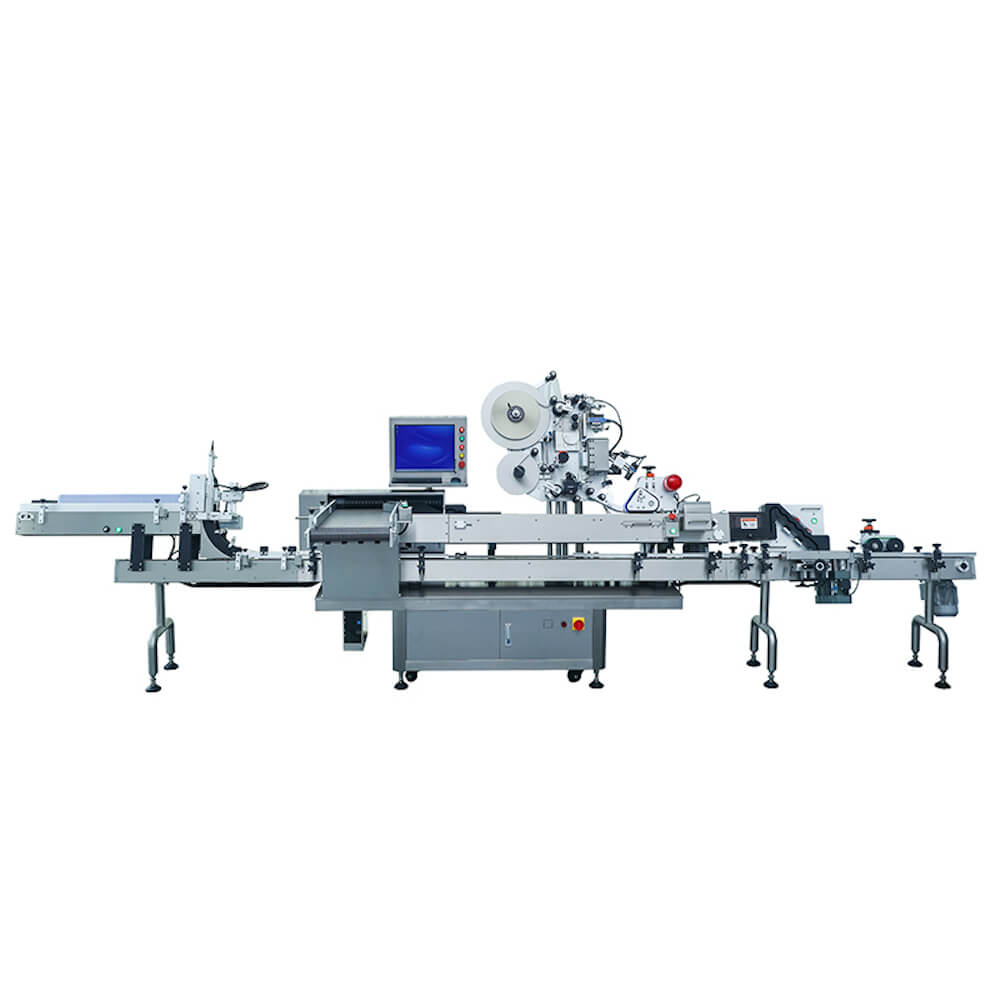

High Speed Horizontal Auto Injector Pen Labeling Machine

- Labeling speed: 0-500 bottles/min

labeling accuracy:±1mm

Applicable bottle diameter: Φ10mm~Φ30mm auto-injection devices

This machine integrates vision inspection to ensure accuracy and quality in the labeling process, which is crucial for the pharma and food industry.

- Various label material compatibility including paper and transparent labels

- Label rolls specifications tailored for diverse labeling requirements

- Customizable features to meet specific operational needs.

- Applicable tray size: length: 50-150mm, width: 60-120mm

- Tray inserting capacity: 30~90 trays/min

- Labeling speed: 0-500 bottles/min

- Labeling accuracy: ±1mm (excluding packaging material error)

- Power supply: 0.4kw, AC220V, 50HZ

- Total weight (approximately): around 380kg

- Noise level: N <75dB (one meter away from the machine)

- Applicable inner diameter of the label roll: φ76mm

- Maximum label roll outer diameter: Φ300mm

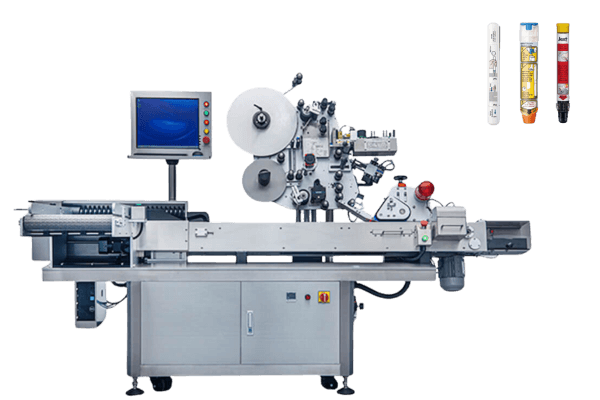

Insulin Injection Pen Labeling Machine with Tray Inserting System

Tray inserting and labeling speed: 30-90 trays/min, 0-500 vials/min

labeling accuracy:±1mm

Applicable product size: Φ10mm~Φ30mm auto pens.Our insulin injection pen labeling machine with a tray inserting system offers a comprehensive line solution. This includes special package labeling and printing systems integrated with product transport systems and quality inspection mechanisms, ensuring a customized, end-to-end solution for the pharma and food industries.

- Labeling of pen injectors in trays.

- High-speed labeling functionality with excellent accuracy

- User-friendly design prioritizing safety and operational comfort

- Well-known servo motors for rapid and precise labeling

- Customizable features to accommodate specific operational requirements and enhance overall efficiency and reliability in pharmaceutical packaging processes.

- Applicable tray size: length: 50-150mm, width: 60-120mm

- Tray inserting capacity: 30~90 trays/min

- Labeling speed: 0-500 bottles/min

- Labeling accuracy: ±1mm (excluding packaging material error)

- Power supply: 0.4kw, AC220V, 50HZ

- Total weight (approximately): around 380kg

- Noise level: N <75dB (one meter away from the machine)

- Applicable inner diameter of the label roll: φ76mm

- Maximum label roll outer diameter: Φ300mm

Prefilled Syringe Auto-Injectors Labeling Machine With Protection Cover

Labeling speed: 0-500 pcs/min

labeling accuracy:±1mm

Applicable product diameter (for small containers): Φ10mm~Φ30mm pharma auto-injection devices- Protective cover for enhanced safety

- High-efficiency motor

- Customizable features based on client needs.

- Suitable for paper and transparent labels

- Label length range: 25mm to 95mm

- Power requirements: 2.5KW, AC220V, 50HZ

- Machine weight: approximately 380Kg

- Noise level: less than 75dB

- Compatible with label rolls having an inner diameter of φ76mm and an outer diameter of up to Φ300mm.

Auto Injection Labeling Importance

It tells you what the medicine is, how much to take, and when it expires. This info keeps you safe and helps you use medicine correctly. For doctors and nurses, the label is crucial for identifying the basic medicine information and making sure it’s the right dose for the patient.

Overall, auto injection labels help streamline the packaging process and ensure that pharmaceutical products are properly labeled for safe use.

Our Labeling Systems for These Pharma Auto-Injection Devices Labeling

Our cutting-edge labeling systems are tailored to address the specific requirements of pharmaceutical auto-injector devices. From prefilled syringe auto-injectors to the latest smart and electronic models, our systems guarantee precise and reliable label application, ensuring compliance with industry standards.

Here’s a closer look at the types of pharma auto-injection devices our systems are equipped to support:

- Prefilled Syringe Auto-Injectors: Ready-to-use devices with a predetermined dose of medication.

- Reusable Auto-Injectors: Designed for multiple uses with the ability to be refilled.

- Disposable Auto-Injectors: Single-use devices intended for disposal after administration.

- Cartridge-Based Auto-Injectors: Utilize cartridges to hold medication for injections.

- Electronic Auto-Injectors: Feature integrated electronics for precise dosing and tracking.

- Manual Auto-Injectors: Require manual activation to administer the injection.

- Smart Auto-Injectors: Capable of connecting to smartphones for reminders and usage tracking.

Why Choose Our Auto Injection Labeling Machine

Our auto-injection labeling machines have some key features that make them really useful:

✅Precision labeling: These machines can apply labels with pinpoint accuracy, ensuring they’re placed correctly on each auto-injection device.

✅High speed: They’re designed to work quickly, which is important for pharmaceutical production where time is critical.

✅Consistency: They apply labels consistently, ensuring each product looks professional and meets quality standards.

✅Compliance: They can include features that ensure labels meet regulatory requirements, which is crucial in the pharmaceutical industry.

✅Integration: They can be integrated into production lines, streamlining the labeling process and improving overall efficiency.

✅Quality control: Some machines have built-in quality control features to check labels for accuracy and alignment, reducing waste and rework.

Customize Your Labeling Machine Using Standard Parts

We make vial labeling machines that fit exactly what you need. Here’s how we do it:

Talk and plan: We chat with you to understand what you need. We use your ideas to sketch out a machine that does exactly what you want.

Build: Once we agree on the design, we start putting it together using the best parts.

Test and check: You get to see your machine work at our place. This is when you can say if it’s perfect or needs a little tweak.

Set up and support: We help set it up at your place and make sure everything runs smoothly. We also help with any paperwork needed to get started.

However, Customizing is typically based on the product’s dimensions, label size, labeling position, and specific requirements to recommend the appropriate model to your needs. Available add-ons or optional features include:

- Connection to the production line for automatic feeding.

- In-line printing capabilities, such as for production batch numbers.

- Missed label detection and elimination feature.

- Automatic collection after labeling.

Auto-Injectors Labeler FAQs

- Can we receive a custom design drawing to fit our factory’s layout?

Yes, our engineering team will gladly provide a custom design draft for your approval without any cost, prior to finalizing your quotation.

- How long will it take to receive a machine after placing an order?

Depending on the specific machine and our production schedule, delivery times typically range from 6 to 8 weeks.

- What payment options are available?

To accommodate your needs, we accept a variety of payment methods, including wire transfers, credit cards, and PayPal.

- What kind of post-purchase support do you offer?

We are committed to supporting your machine throughout its entire life cycle with online technical support, parts provision, and maintenance services.

- Is training provided for machine operation and maintenance?

Absolutely, we provide free online training to ensure you are fully equipped to use and maintain your machine effectively.

- What is the warranty period for your machines?

Our machines are covered by a 1-year warranty as standard, with the possibility to extend this warranty upon request.

More Labeling Solutions For Pharmaceutical Products

Ampoule labeling

Labeling ampoules presents unique challenges in the pharmaceutical industry.

Tamper Evident labeling

Labeling tamper-evident seals provides a method for security-conscious brands.

Tube labeling

Affixing labels to medicine tubes remains a vexing mission for healthcare providers.

Let’s work together

We’d love to hear from you! Send us a message using the form opposite, or email us. We’d love to hear from you! Send us a message using the form below.