Wrap-Around Labeling Machine

Finding it hard to label your round pharmaceuticals? Wrap-around labeler systems can handle all your round bottles, jars, tubes, vials, syringes, and ampoules. Streamline your labeling process today.

- Works with every type of round pharmaceutical container.

- Exceptionally high efficiency in wrap-around labeling.

- Unmatched precision with an accuracy of ±1mm.

- Streamlined packaging processes, supported comprehensively.

Viallabeller Labeler Systems for Wrap-around Labeling

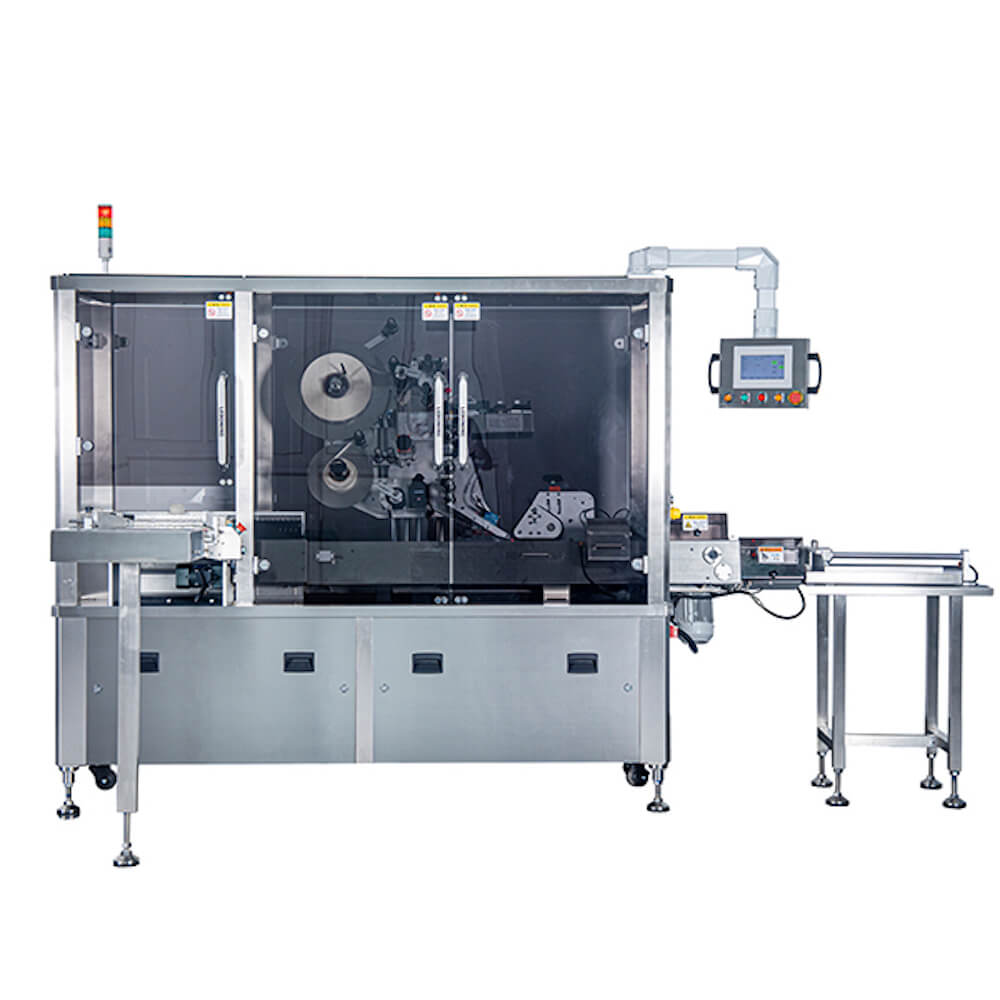

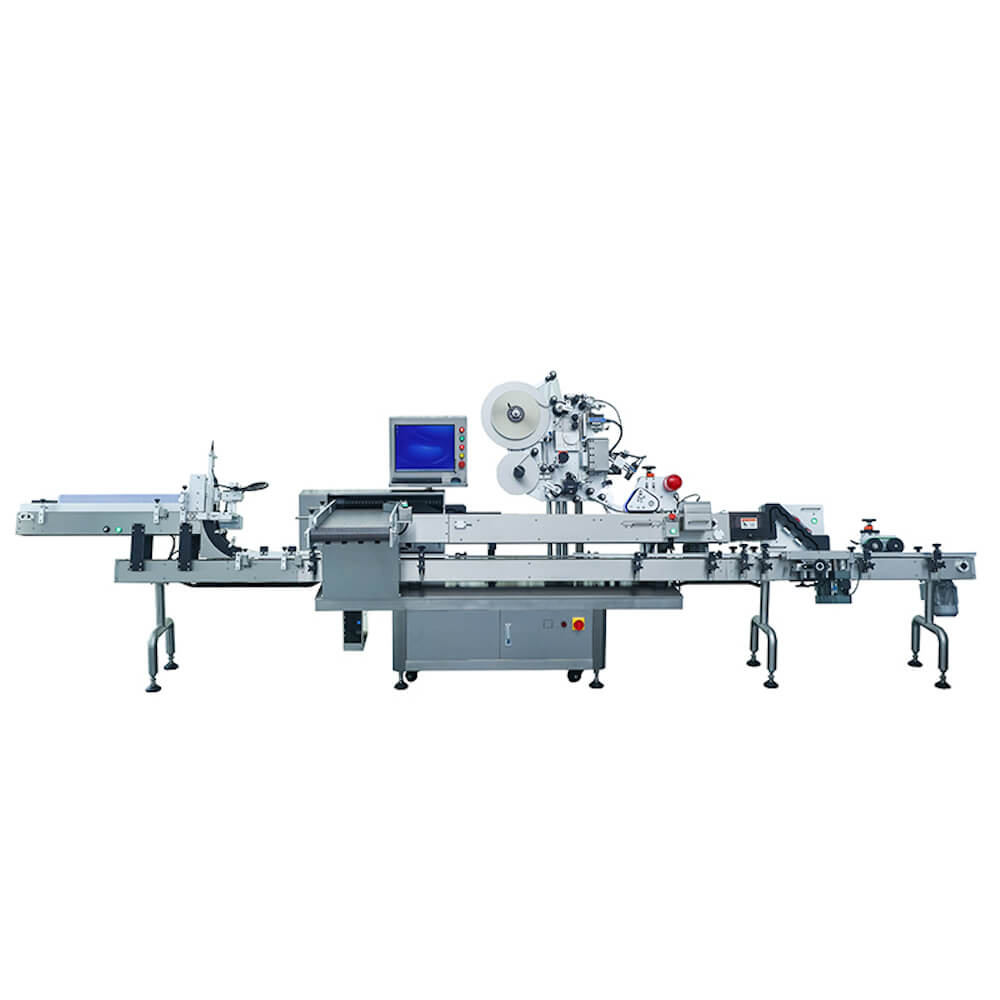

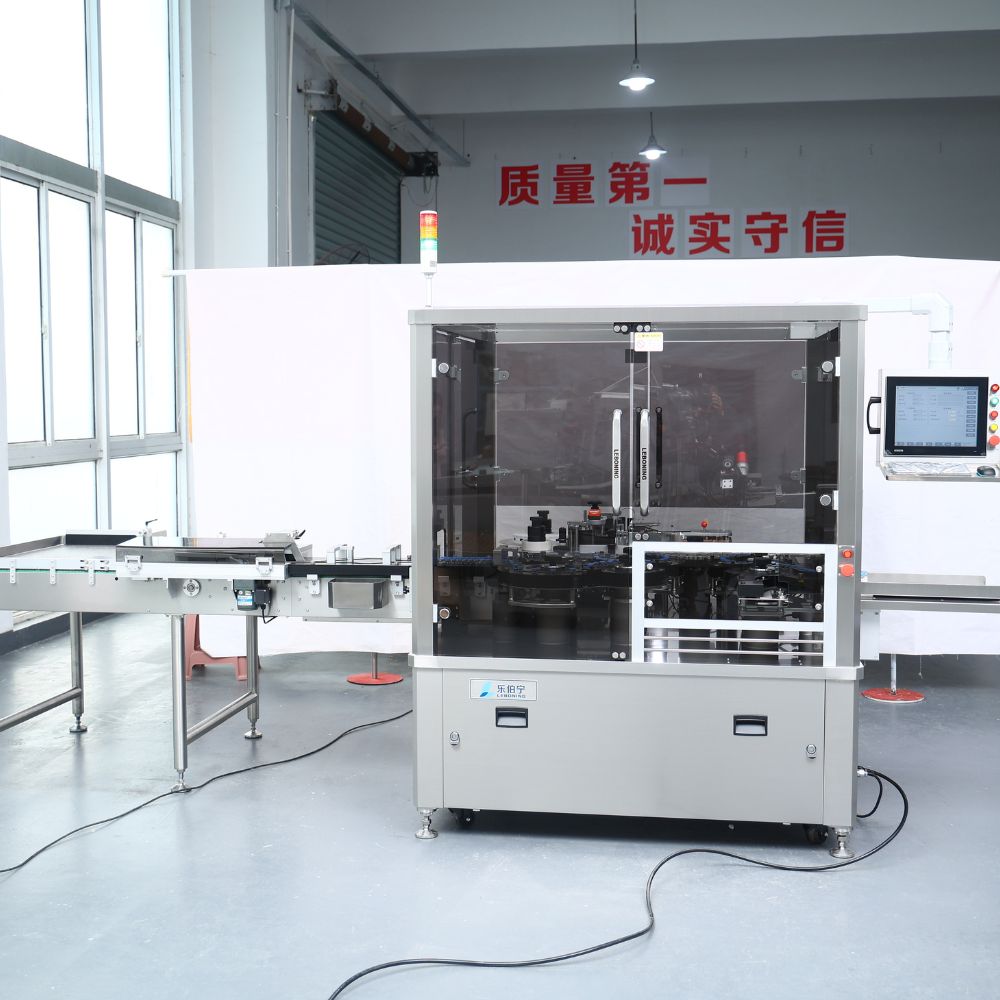

We offer two types of fully automatic labeling systems for wrap-around labeling: horizontal systems and vertical systems.

See our labeling machines below to find the perfect fit for your needs:

Why Choose VialLabeller Systems for Wrap Around Labeling?

VialLabeller offers market-proven automated systems that meet the stringent requirements. With 18 years of experience, we understand your needs. VialLabeller has the expertise to provide customized wrap around labeling machines.

Worldwide Countries Shipped

Years of Marketing Experience

Customer Satisfaction Guaranteed

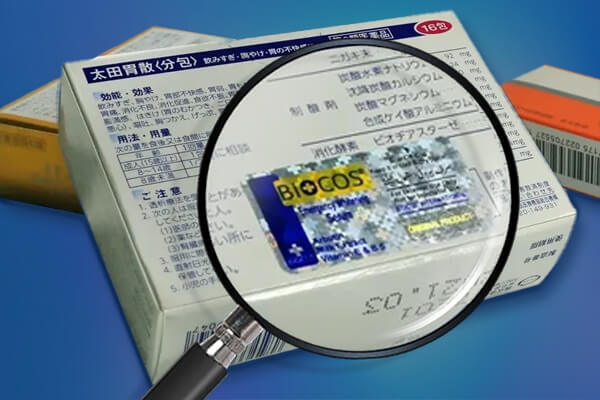

Seamless Wrap-around Labeling for All-around Pharmaceuticals

The wrap-around labeling machine is a device used to automatically apply labels to the surface of cylindrical containers (bottles, cans, ampoules, vials, etc.).

Warp around systems use a robotic arm to apply labels while the container spins on a conveyor belt. This ensures the label fits perfectly. They work with different label materials, providing strong adhesion and a good look. Waterproof and weatherproof options enhance the labels to last longer.

These labeling systems handle large amounts of products quickly. They are widely used in the food, beverage, cosmetic, pharmaceutical, and chemical industries.

Below are some applications of our wrap-around labeling machines in the pharmaceutical industry:

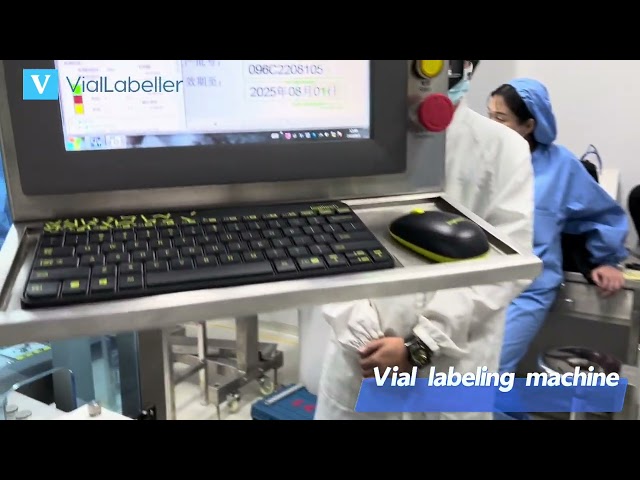

Machine Videos

The videos show our machines handle different pharmaceuticals and labeling requirements. You will know the comprehensive overview of labeling solutions for pharmaceuticals.

Labeling on taper bottles video

Labeling on 2 ml vial bottles video

Labeling on ampoules video

Labeling on 20 ml vials video

Labeling on 100ml Syrup Bottles video

Labeling on 10ml Oral Liquid Bottles video

FAQs

- What labeling technology does our warp-around labeling machine utilize?

Self-adhesive labeling.

- What surfaces can be labeled using the wrap-around labeling machine?

Wrap-around labeling machines can label cylindrical, curved, and rounded surfaces.

- Can we receive a design drawing customized for our specific factory layout?

Certainly! One of our skilled engineers will create a personalized design drawing at no additional cost for you to review prior to finalizing your quote.

Let’s work together

We’d love to hear from you! Send us a message using the form opposite, or email us. We’d love to hear from you! Send us a message using the form below.