Automatic Vial Labeling Machine

Struggling with slow labeling for your vials? Our fully automatic systems label 1ml to 100ml vials quickly and accurately. They help handle labeling for vaccines, liquid meds, and other drugs.

- Adaptable for any vial size, with ±1mm precision.

- High-volume labeling efficiency.

- Fast turnaround and full support.

- Meet the compliance standards of the pharmaceutical, lab, and cannabis sectors.

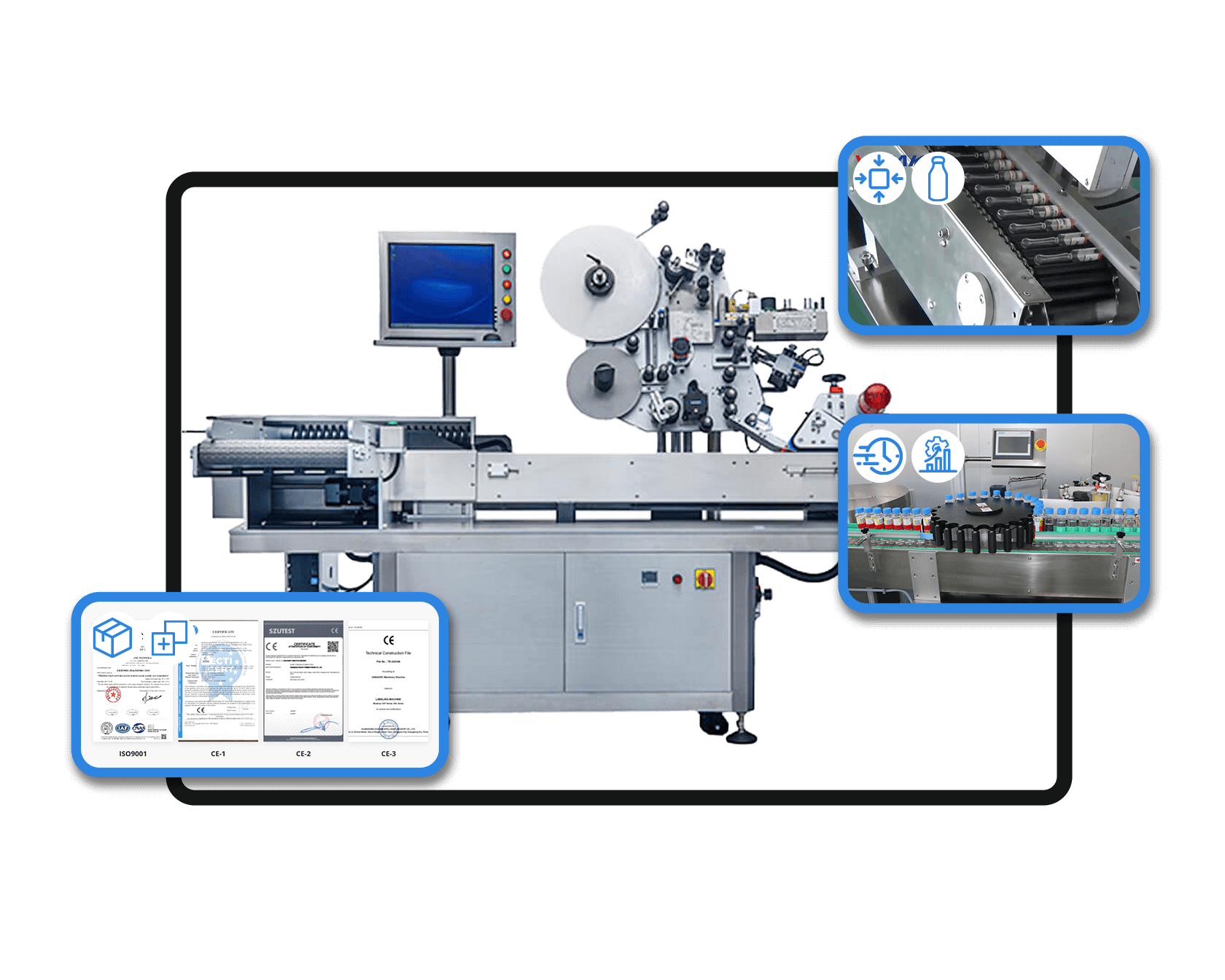

Our Labeling Systems for the Labeling of Vials

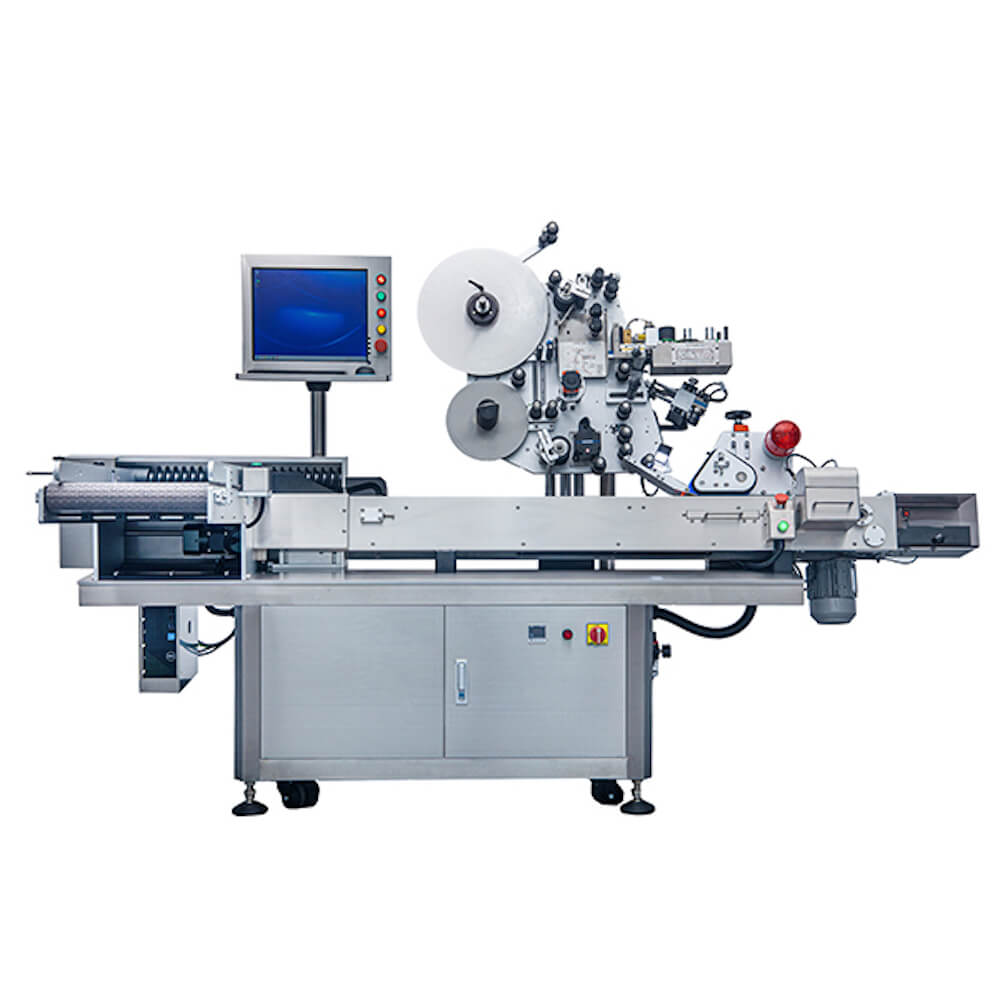

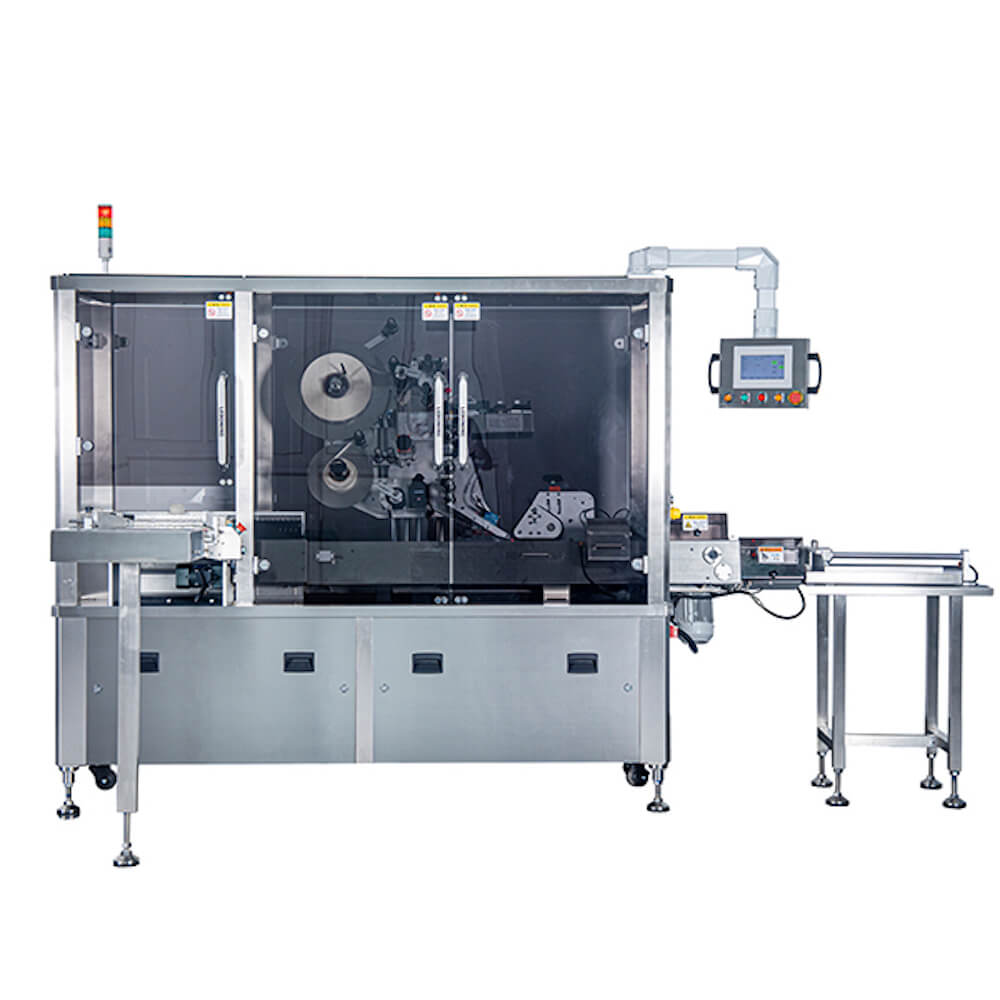

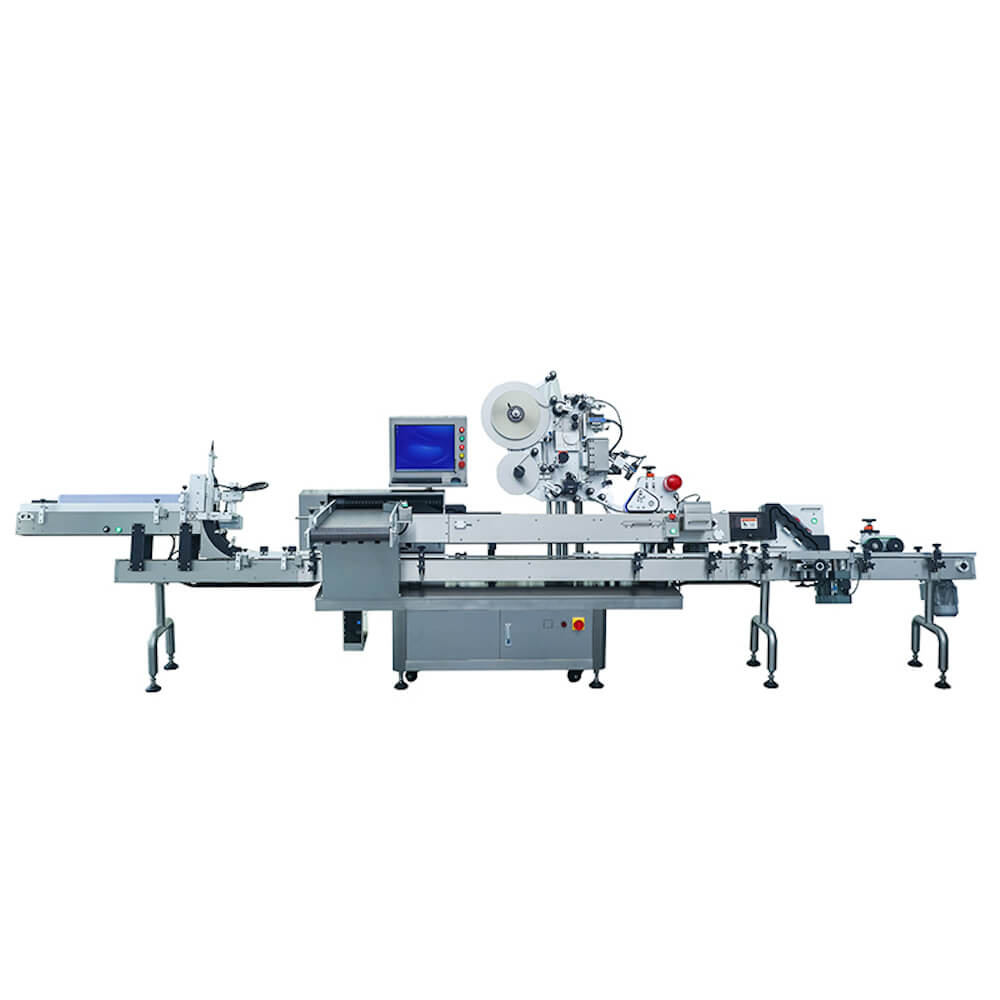

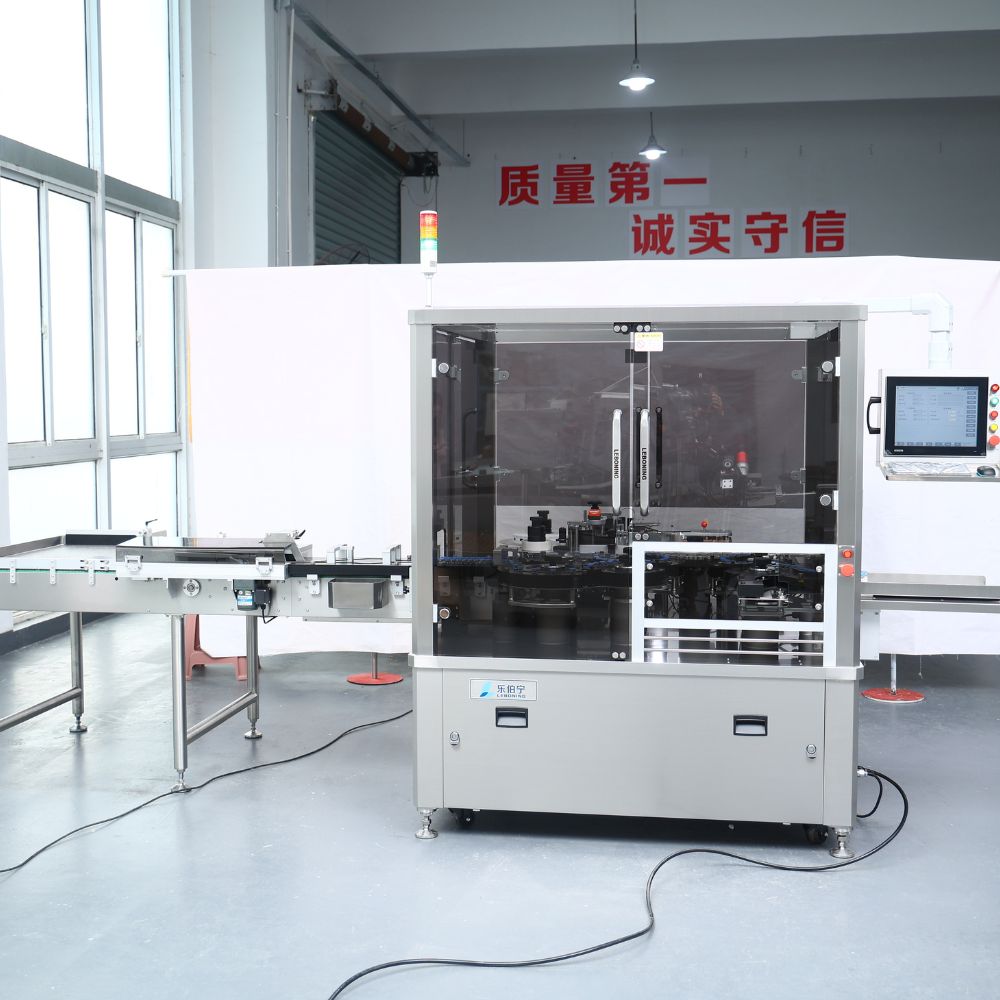

We offer 2 main types of systems for vial labeling: wrap-around systems and horizontal systems. See our automatic labeling systems for vials below:

Why Choose VialLabeller Systems for Vials?

As the top choice for pharma companies. we offer reliable, efficient, and compliant vial labeling solutions. Our systems use thermal transfer printing. They handle different containers and ensure accurate labels for unique production needs. We meet your pharma packaging requirements with care.

Worldwide Countries Shipped

Years of Marketing Experience

Customer Satisfaction Guaranteed

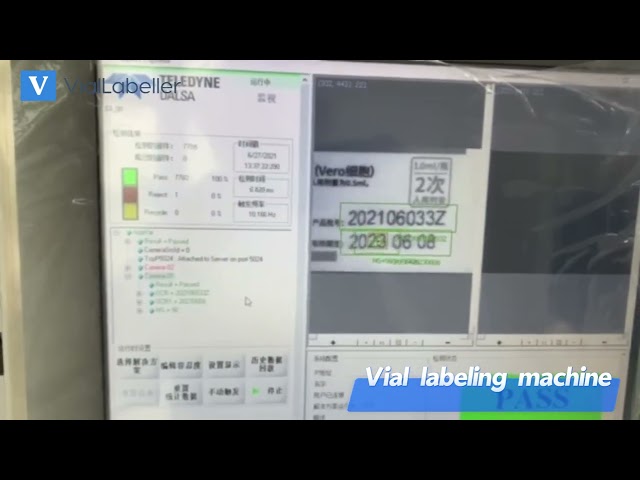

Machine Videos

In our vial labeling machine videos, you will see how the machine applies labels accurately on different vial sizes, even at high speeds.

The videos show the machine’s simple design. It can handle various vial sizes without needing to change parts. It also works with transparent (No Look) labels. It will show you that the machine fits easily into existing production lines. It provides fast, flexible labeling solutions.

10 ml vial labeling machine video

2 ml rotary vial labeling machine(650 bpm) video

5 ml horizontal vial labeling machine video

Rotary 2 ml vial labeling machine video

2 ml rotary vial labeling machine video

Horizontal vial labeling machine video

FAQs

- How do I choose the right labeling system for vial labeling, considering the wrap-around and horizontal labeling systems?

To choose the right labeling system for vials, consider the following:

Wrap-Around Systems: Ideal for vials that can stand upright. Wrap-around labeling systems are predominantly used for vials. They apply labels to rounded containers by fully or partially wrapping them around the vial body. These systems ensure accurate label placement. even labeling at high speeds and including quick-change features to fit different vial sizes. They also have features like vision inspection to check for label accuracy and codes to meet industry rules.

Horizontal Systems: Best for vials that cannot stand upright. Horizontal labeling systems are for rounded bottles or pharma containers that can’t stand upright. These systems hold the container horizontally during labeling, providing enhanced stability and accuracy. Horizontal systems support batch coding and inspection, ensuring compliance with pharmaceutical packaging regulations.

- What types of labels can VialLabeller solution handle?

Our solutions are compatible with various types of labels, including pressure-sensitive, adhesive, and tamper-evident labels. We can also accommodate different label materials and finishes.

- Is training available for machine operation and maintenance?

Indeed, we provide complimentary online training sessions to empower you with the necessary expertise for the machine’s effective operation and upkeep.

- What does the machine warranty cover?

Each machine is backed by a standard 1-year warranty, with the option to extend this period at your request.

Let’s work together

We’d love to hear from you! Send us a message using the form opposite, or email us. We’d love to hear from you! Send us a message using the form below.