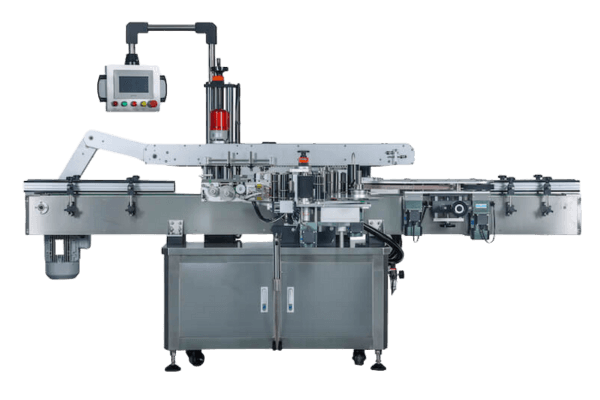

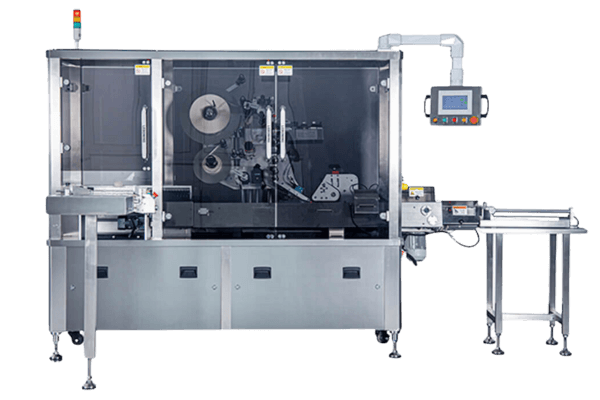

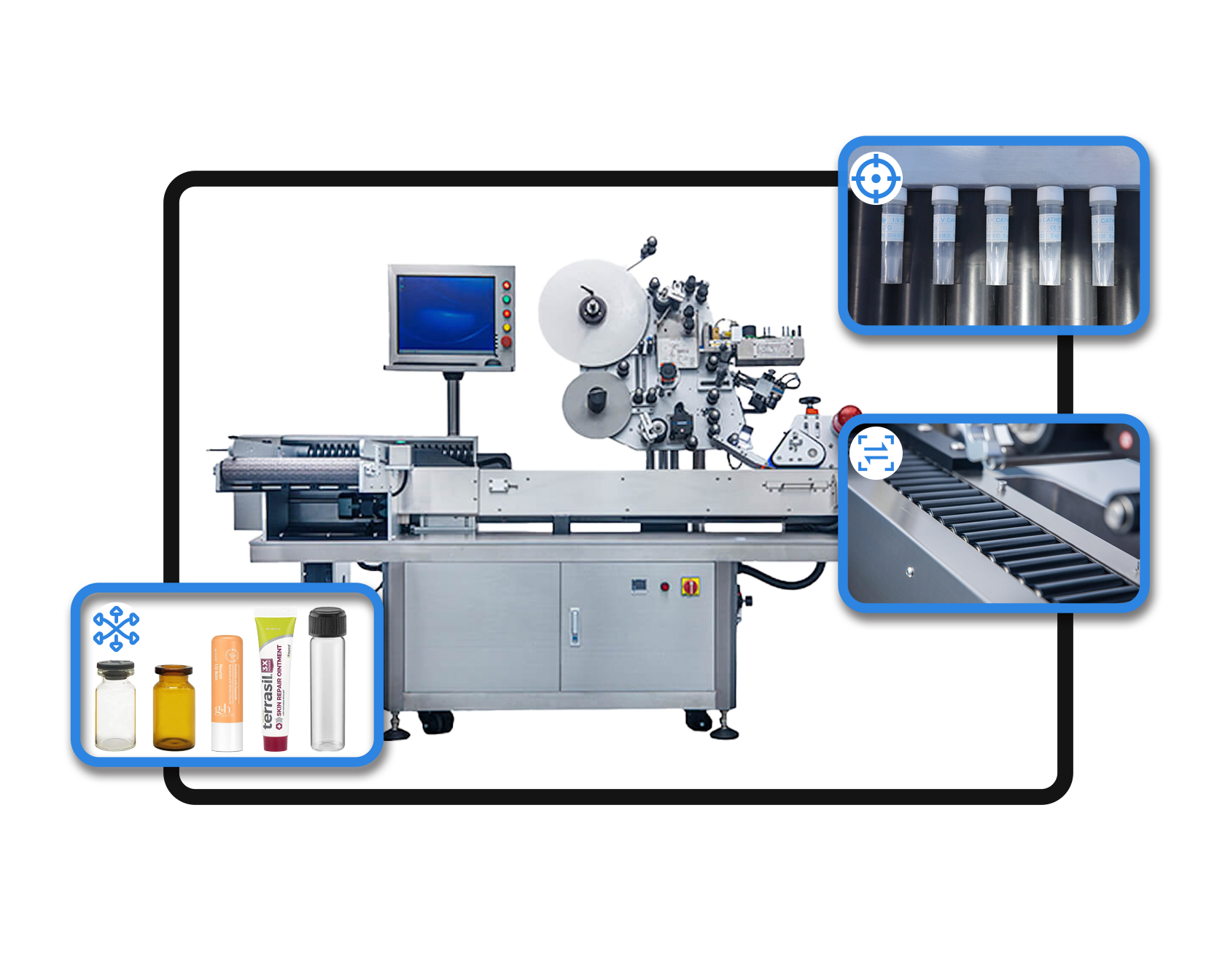

Automated Tube Labeling Machine

Struggling with slow and inconsistent tube labeling? Our automatic systems label tubes from 0.5 ml to 50 ml. These systems help speed up the labeling process for glass test tubes, blood collection tubes, lip balm, aluminum tubes, centrifuge tubes, and more.

- Compatibility with all tube materials

- Superior tamper-evident labeling efficiency

- Unrivaled accuracy of ±1mm

- Optimized packaging workflow with comprehensive Support

- Enhanced efficiency and accuracy in sample processing with automated labeling system

Our Labeling Machines for Pharma Tubes

With 19 years experience, our labeling solutions ensure accurate labels on your tubes to meet the standards of pharmaceutical packaging.

See our labeling systems for tubes in the pharma industry:

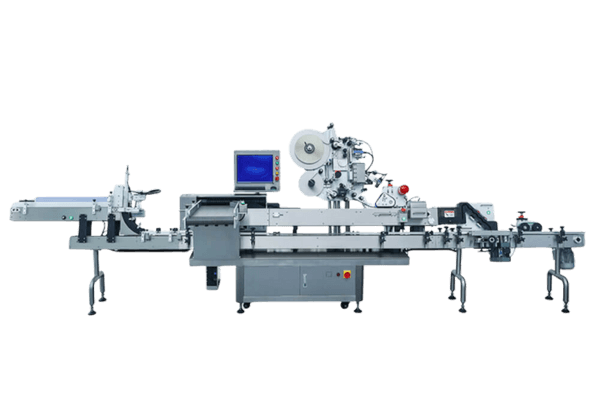

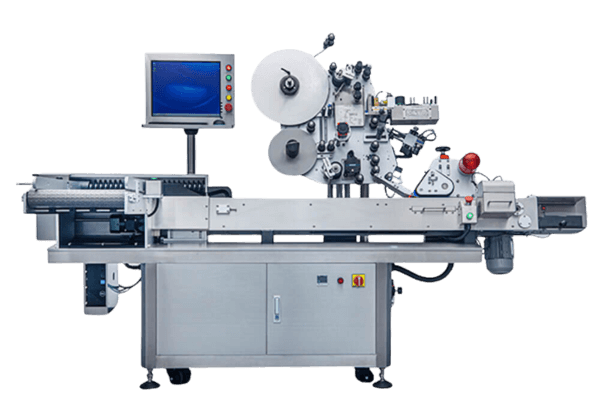

Why Choose Our Systems for Tube Labeling

Our tube labeler solutions can be customized to meet the specific needs of various industries, including pharmaceuticals and cosmetics.

Customizing is typically based on the product’s dimensions, label size, labeling position, and specific requirements to recommend the appropriate model to your needs.

Available add-ons or optional features include:

- Connection to the production line for automatic feeding.

- In-line printing capabilities, such as production batch numbers.

- Missed label detection and elimination feature.

- Automatic collection after labeling.

60+

Worldwide Countries Shipped

18+

Years of Marketing Experience

1000+

Customer Satisfaction Guaranteed

Our Tube Labeling Samples

Let’s work together

We’d love to hear from you! Send us a message using the form opposite, or email us. We’d love to hear from you! Send us a message using the form below.