Tray insertion plays a crucial role in modern logistics and production processes. At its core, tray insertion involves placing trays into designated slots or areas in machinery or packaging systems to streamline operations.

This process is integral to maintaining efficiency and accuracy in handling and processing goods across various industries. With the rise of automation and advanced machinery, understanding tray insertion’s nuances becomes essential for optimizing workflow and minimizing downtime.

Basic operations of tray insection

Tray insertion encompasses a variety of operations, each tailored to specific needs and machinery. Proper installation of tray insertion equipment is crucial to ensure safety and functionality. Trays come in different types and sizes, designed to accommodate various products and purposes.

Typically, trays are constructed from materials like plastic, metal, or cardboard, chosen based on durability, weight, and product compatibility. Choosing the right material for trays is essential to avoid corrosion and damage.

The basic construction of insertion equipment generally includes a tray feeder, conveyor system, and insertion mechanism. The tray feeder holds and organizes trays, while the conveyor system transports them to the insertion point.

The insertion mechanism, which may be pneumatic, hydraulic, or mechanical, precisely places the tray in the correct position. Operators must be well-versed in the operational flow and ensure all equipment components are functioning properly to avoid disruptions.

Role in labeling machines

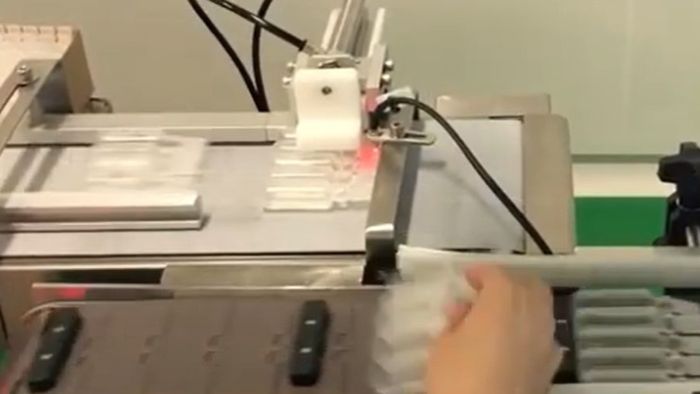

Labeling machines are pivotal in packaging and product identification, and tray insertion significantly impacts their efficiency. Labeling machines operate by applying labels to products as they move through the system.

Regular inspection is crucial to ensure trays are correctly aligned and spaced for accurate labeling. Proper tray insertion ensures that products are correctly aligned and spaced, allowing the labeling machine to apply labels accurately and consistently.

The interaction between tray insertion and labeling machines is critical. For instance, if trays are not inserted correctly, products might not align properly, leading to mislabeling or wasted labels. Efficient tray insertion systems can enhance labeling accuracy, reduce errors, and improve overall productivity.

Real-world applications illustrate how optimizing tray insertion can lead to significant gains in labeling speed and accuracy, directly affecting production output and quality.

Some of Viallabeller’s labeling machines, such as the Y500 and Y510, are equipped with a tray insertion function and can label ampoules, syringes, and vials.

Compatibility with automation systems and installation

As industries increasingly adopt automation, the compatibility of tray insertion systems with automated processes becomes more important. It is crucial to understand the critical steps in the process of ensuring these systems work seamlessly with automation.

Automated systems require precise and reliable tray insertion to function correctly. This includes ensuring that trays are inserted with the correct orientation and at the right time to synchronize with automated conveyors, sorting mechanisms, and packaging units.

Compatibility issues can arise, such as misalignment or timing discrepancies, which can disrupt the entire automated system. To address these challenges, manufacturers need to design tray insertion systems that integrate seamlessly with existing automation infrastructure.

Solutions include advanced sensors, programmable logic controllers (PLCs), and sophisticated control systems that enhance coordination between tray insertion and automated machinery. Additionally, it is essential to test the integration of tray insertion systems with automation infrastructure to ensure compliance with standards and safety measures.

Maintenance, inspection, and troubleshooting

Regular maintenance and troubleshooting are essential to ensure the longevity and reliability of tray insertion systems. It is crucial to emphasize the importance of cleaning specific areas within tray insertion systems to prevent operational disruptions.

Common issues include tray jams, misalignment, or wear and tear on mechanical components. Routine inspections and preventive maintenance can mitigate these problems and reduce the costs associated with operational disruptions.

Operators should follow a maintenance schedule that includes checking moving parts, lubricating components, and inspecting electronic systems. Personal safety is paramount during maintenance and troubleshooting activities, requiring proper safety training and communication protocols.

Troubleshooting involves identifying the root cause of issues, such as examining whether jams are due to misaligned trays or worn-out parts. Implementing a structured approach to maintenance and troubleshooting helps maintain optimal performance and extend the service life of tray insertion equipment.

Conclusion

Tray insertion is a foundational element in efficient logistics and production systems, impacting various processes, including labeling and automation. By understanding the intricacies of tray insertion and its role in machinery, companies can enhance productivity, minimize errors, and ensure smoother operations.

The ongoing advancements in technology and automation highlight the importance of continually refining tray insertion techniques to keep pace with industry demands. Embracing these improvements ultimately leads to more efficient and effective tray insertion, driving better overall performance in production and packaging environments.