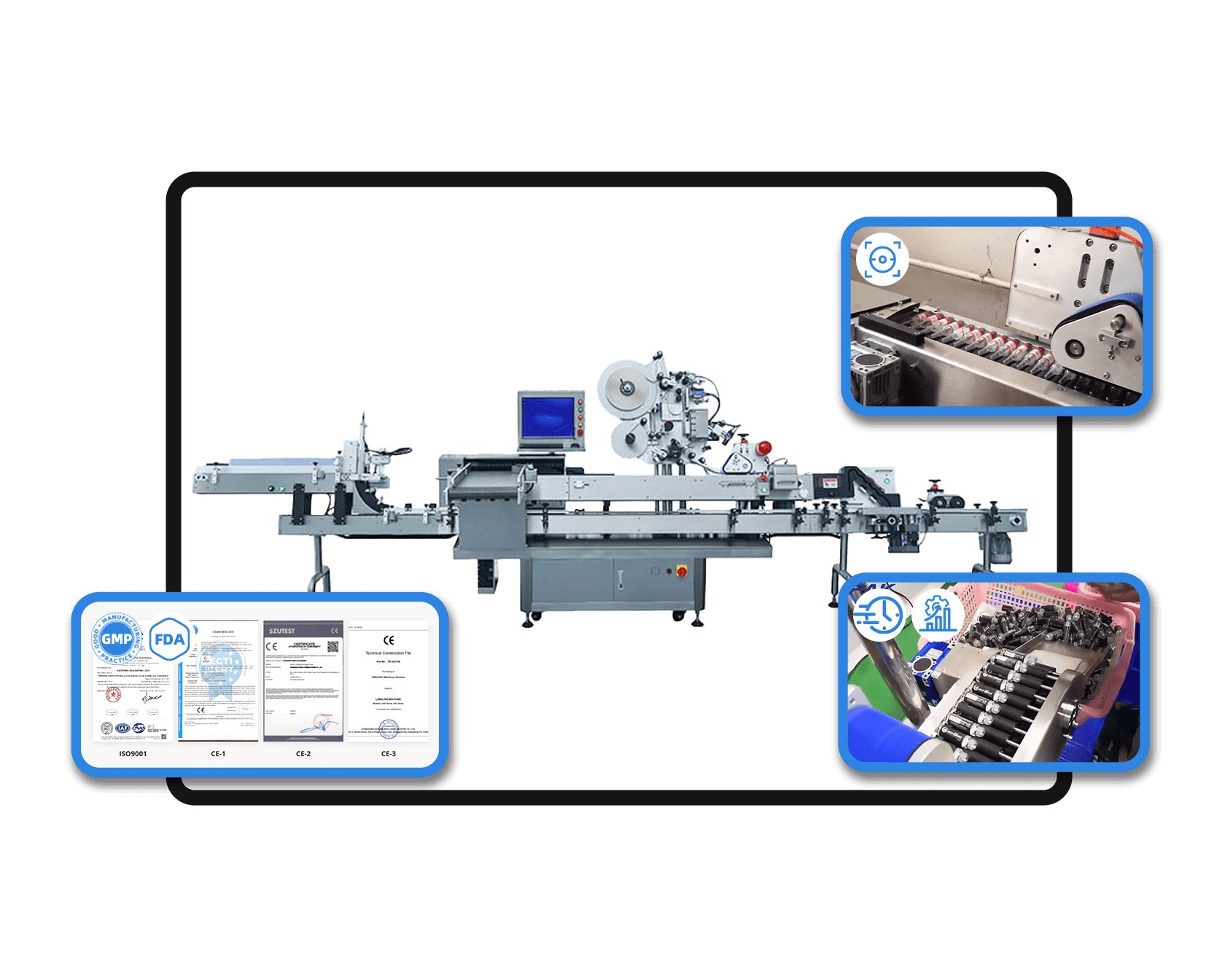

Automatic Ampoule Labeling Machine

Having trouble with ampoules can’t moving smoothly on conveyors? Our advanced labeling machines make transport easy and label accurately. Boost your efficiency and cutting downtime.

- Adaptability across all ampoule dimensions

- Exceptional high-speed Labeling Performance

- Flawless accuracy of ±1mm

- Streamlined process with full support

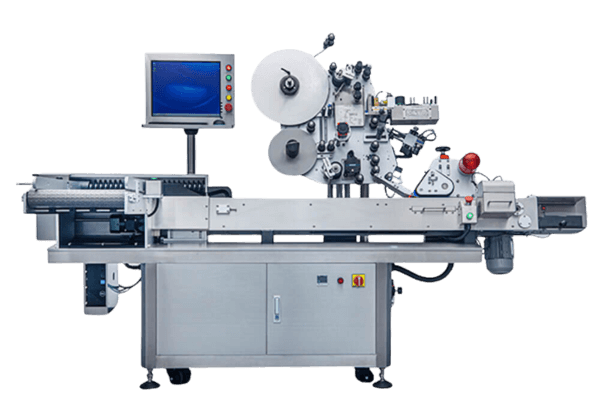

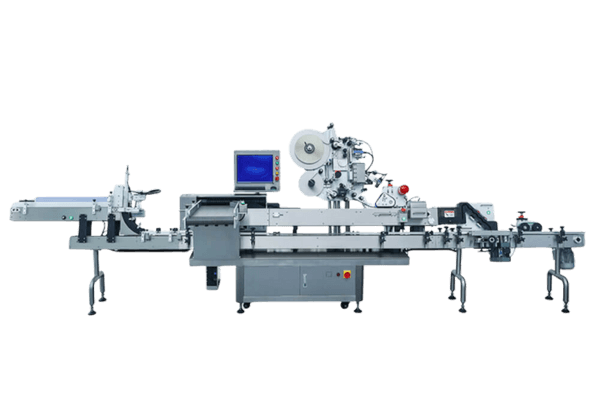

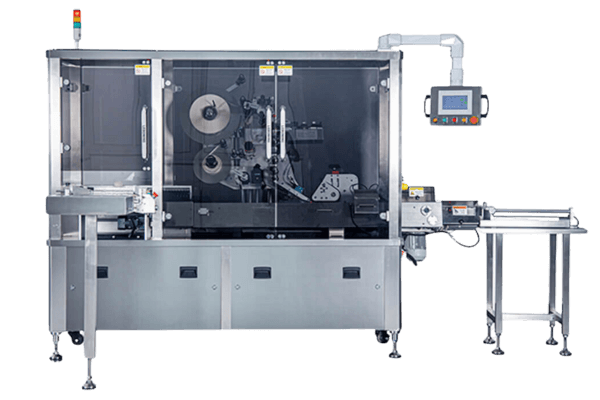

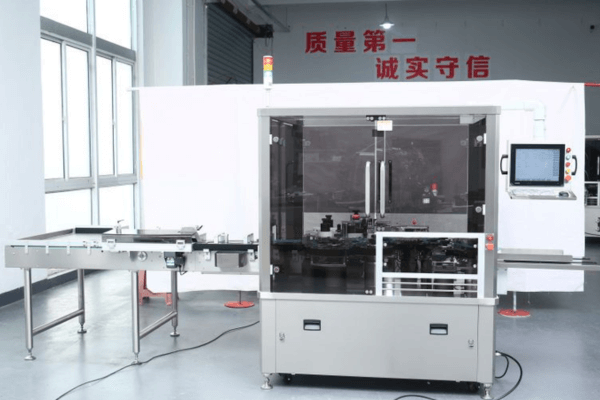

Types of Ampoule Labeling Machine

We fabricate and supply a wide range of automated labeling machines for ampoules. Options include in-linear, horizontal, vertical, wrap-around, and rotary machines.

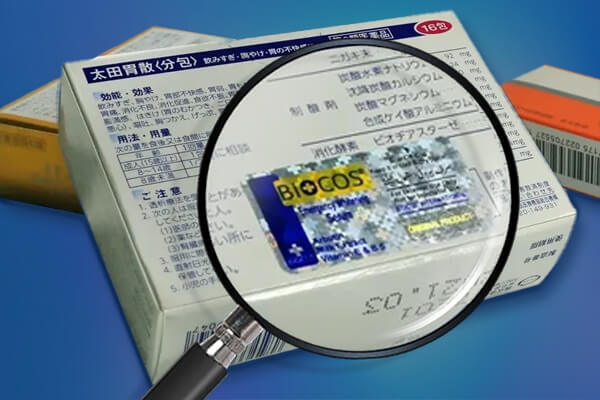

Why Choose VialLabeller Ampoule Labeling Systems?

VialLabeller offers specialized ampoule labeling solutions tailored for the pharmaceutical industry. We provide a range of machines for ampoule labeling, including wrap-around, horizontal, and rotary systems.

Worldwide Countries Shipped

Years of Marketing Experience

Customer Satisfaction Guaranteed

Machine Videos

You’ll see how it ensures precise label placement on various ampoule sizes, even at high speeds. The videos highlight user-friendly features, compatibility with different label types, and seamless integration into existing production lines.

Rotary labeling machine for 1 ml ampoules(650 bpm)

Rotary labeling system for 5 ml ampoules

Horizontal labeling machine for 2 ml ampoules

Vertical sticker labeling machine with packaging line for 20ml ampoules video

Top labeling machine for 5 connected plastic ampoules video

Rotary labeling machine and boxing system for ampoules video

Let’s work together

We’d love to hear from you! Send us a message using the form opposite, or email us. We’d love to hear from you! Send us a message using the form below.