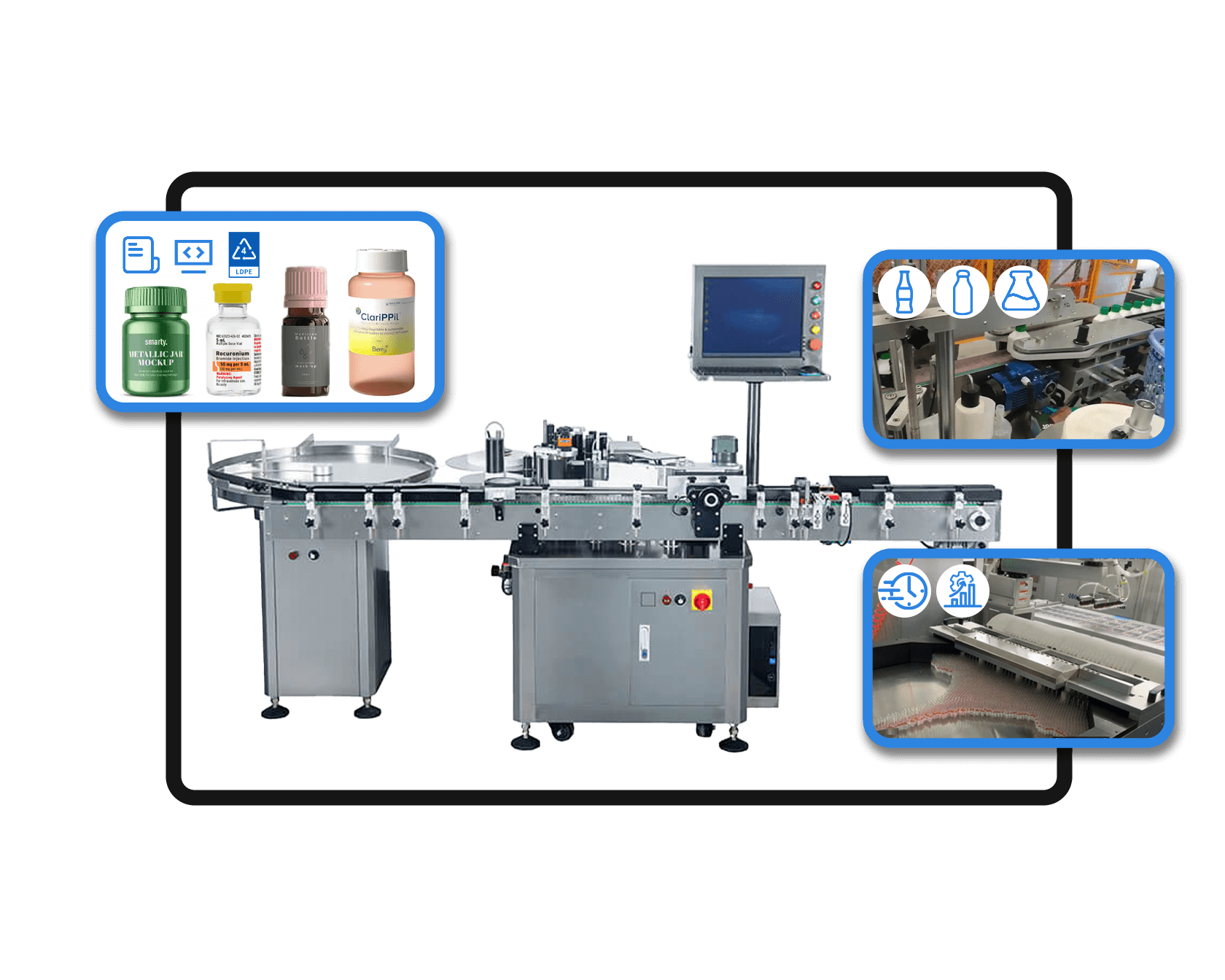

Bottle Labeling Machine

Struggling with slow and inaccurate labeling for your medicine bottles? VialLabeller offers high-quality labeling machines for medicine bottle labeling. They ensure fast, precise labeling for all bottle shapes.

- Works for all types and shapes of medicine bottles.

- High efficient for labeling bulk bottles quickly.

- High accurate, up to ±1mm.

- Fast to set up and custom support.

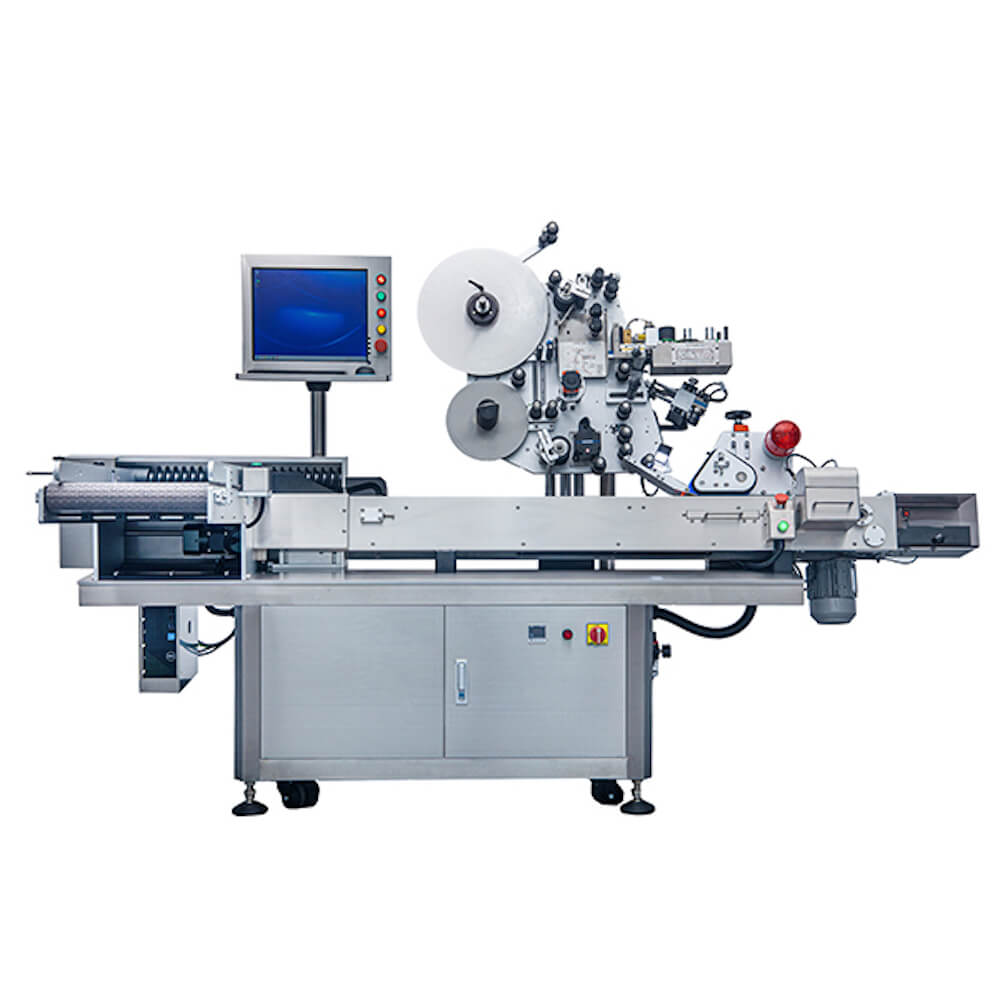

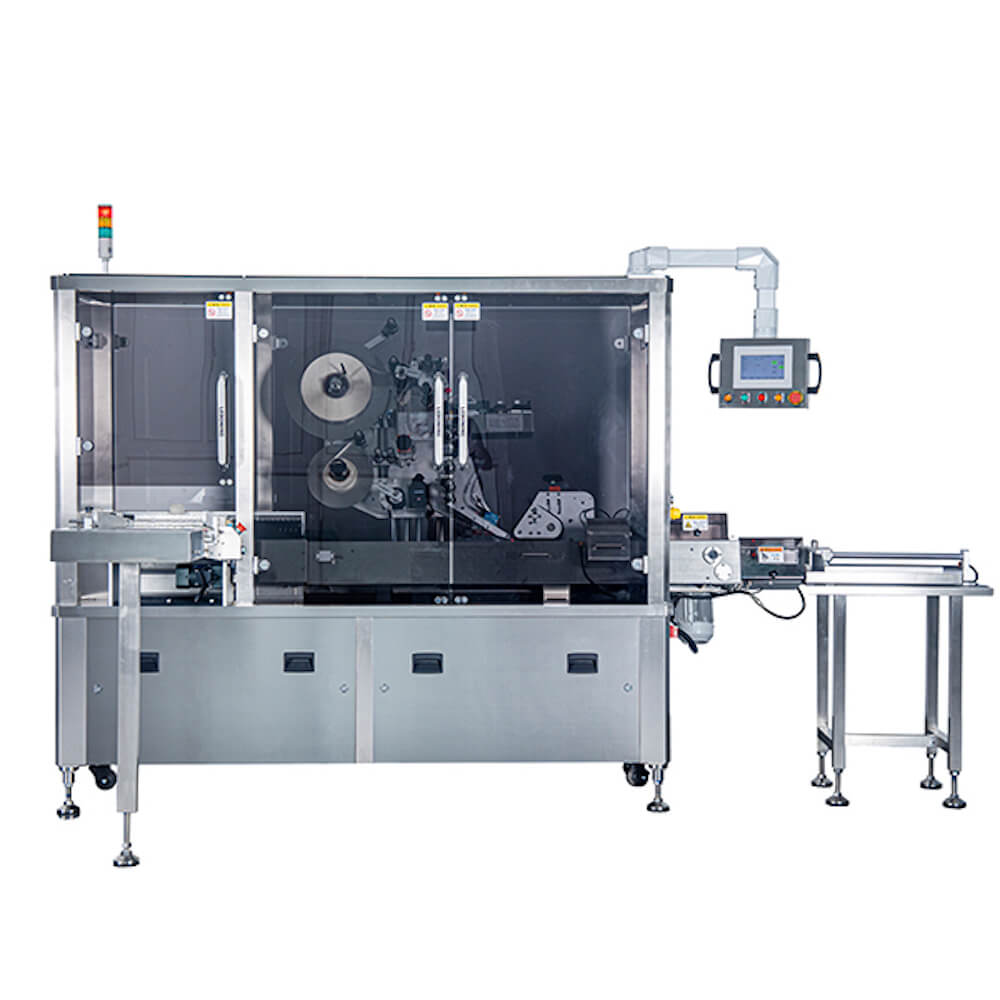

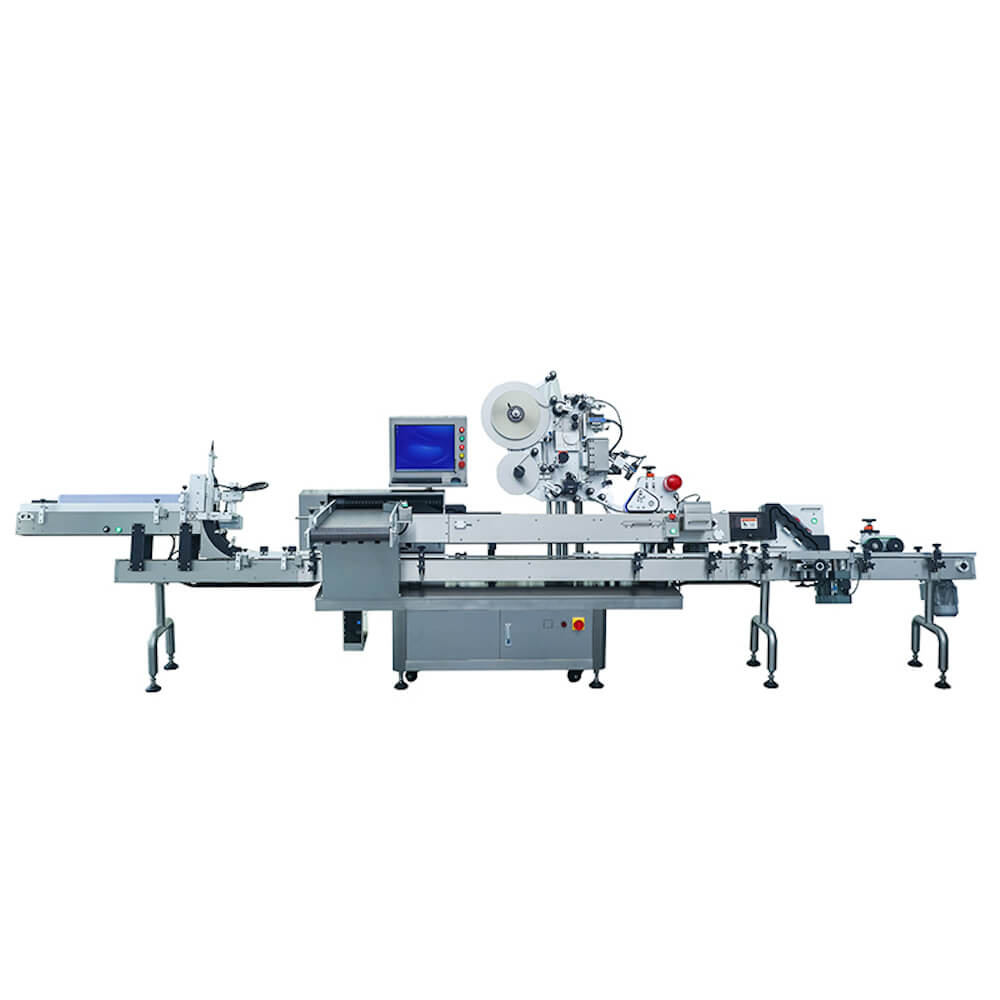

Automatic Labeler Systems for Bottles

VialLabeller has fast and accurate labeling machines that meet pharmaceutical labeling standards. Our systems label medicine stickers on bottles shaped like oval, round, square, tapered, or flat, handle medicine bottle sticker lengths from 25 to 95 mm.

See our labeling machines below to find the perfect fit for your needs:

Why Choose VialLabeller Systems for Bottle Labeling?

VialLabeller offers market-proven automated systems that meet the stringent requirements. With 19 years of experience, VialLabeller systems ensure each sticker is applied with precision and consistency. Keep your drug production line efficient and compliant with regulations.

Worldwide Countries Shipped

Years of Marketing Experience

Customer Satisfaction Guaranteed

Label Placement for Pharmaceutical Bottles

Our fully automatic systems for labeling on medicine bottles. Such as labeling on these round bottles: pet bottles, plastic bottles, dropper bottles, vials, ampoules, syrup bottles, pill bottles, tapered bottles.

Below are some applications of our bottle labeling machines in the pharmaceutical industry:

Machine Videos

Watch these videos to see different bottle labeling machines in action. Each machine works fast and labels bottles of all shapes and sizes with accuracy.

Y 400 labeling machine for round bottles video

Y 510 labeling machine for oral bottles video

Y 500 labeling machine for vials video

FAQs

- What types of medicine bottles can be labeled?

Our machines can handle various types of pill bottles, including round, oval, and square bottles. Our machines can also adjust for tapered bottles. We support customized services for your shaped pill bottles.

- What labeling methods are used for pharma bottles?

Our common labeling methods are wrap-around labeling and pressure-sensitive labeling. These methods are fast and effective for applying labels to pill bottles.

- What information should be included when labeling medicine bottles?

Medicine labels should show the product name, dosage instructions, active ingredients, expiration date, batch number, storage instructions, manufacturer’s contact info, and any warnings or safety notes.

- What is the labeling speed?

These machines vary in speed, typically ranging from 300 to 500 bottles per minute, depending on the machine model and bottle size.

- How accurate are bottle labeling machines?

Our labeling systems offer an accuracy of ±1mm, ensuring precise label placement to meet industry standard.

- Is training available for using and maintaining the machine?

Yes, we offer free online training to teach you how to use and take care of the machine properly.

- What does the machine warranty cover?

Each machine comes with a 1-year warranty, and you can ask to extend it if needed.

Let’s work together

We’d love to hear from you! Send us a message using the form opposite, or email us. We’d love to hear from you! Send us a message using the form below.