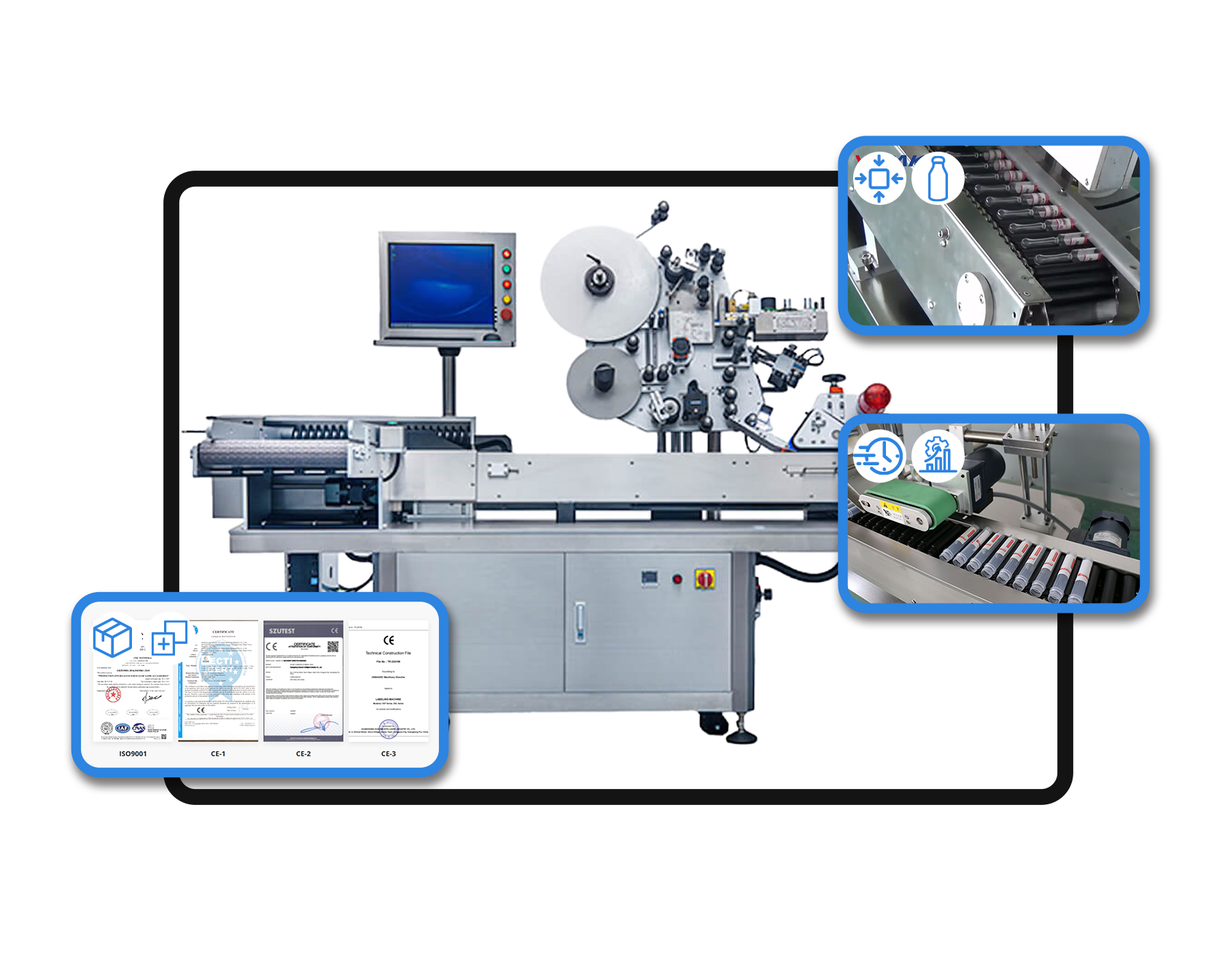

Automatic Horizontal Labeling Machine

Having trouble labeling round and odd-shaped containers? Get perfect alignment with a horizontal labeling machine. Improve your production line now.

- For small round pharma containers with irregular surfaces.

- Efficient horizontal labeling performance.

- High accuracy down to ±1mm precision.

- Efficient labeling workflows, fully supported.

Viallabeller Labeling Systems

The horizontal labeling machine labels small round bottles like ampoules. It also works for narrow items that can’t stand upright like syringes, and pens.

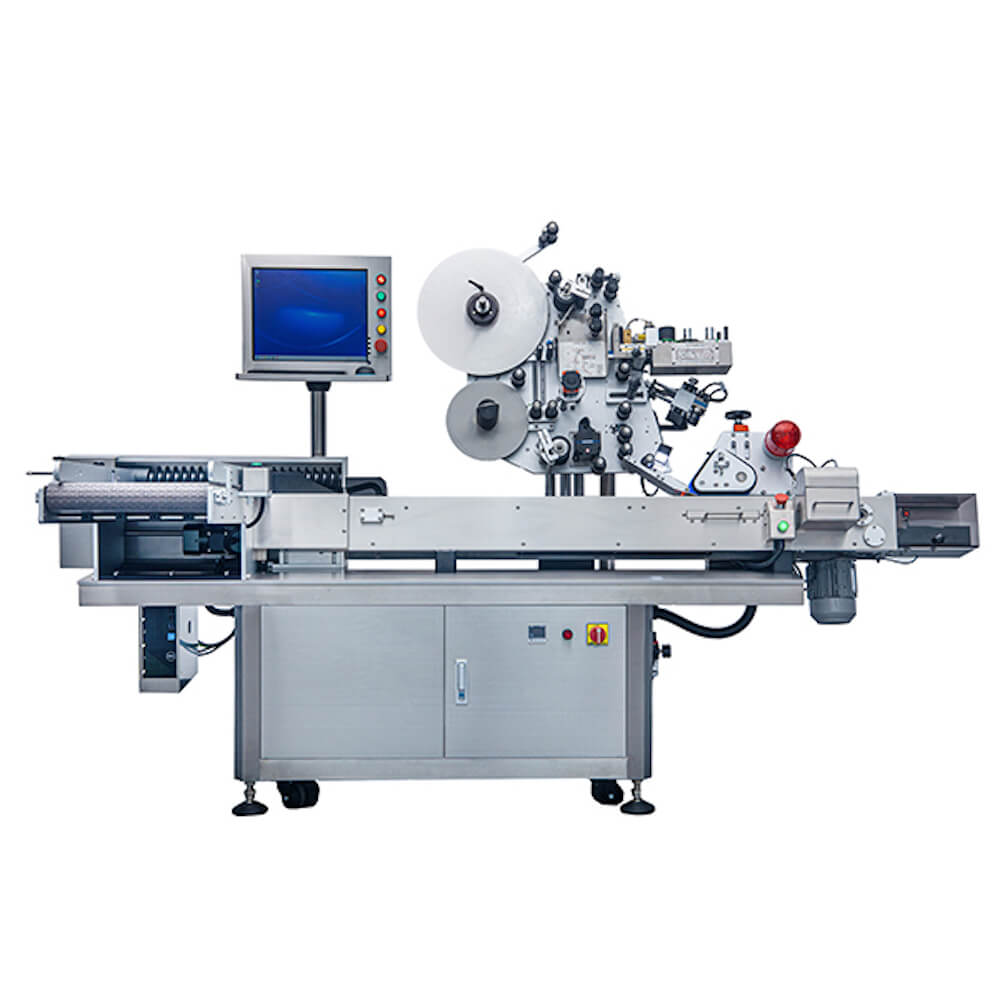

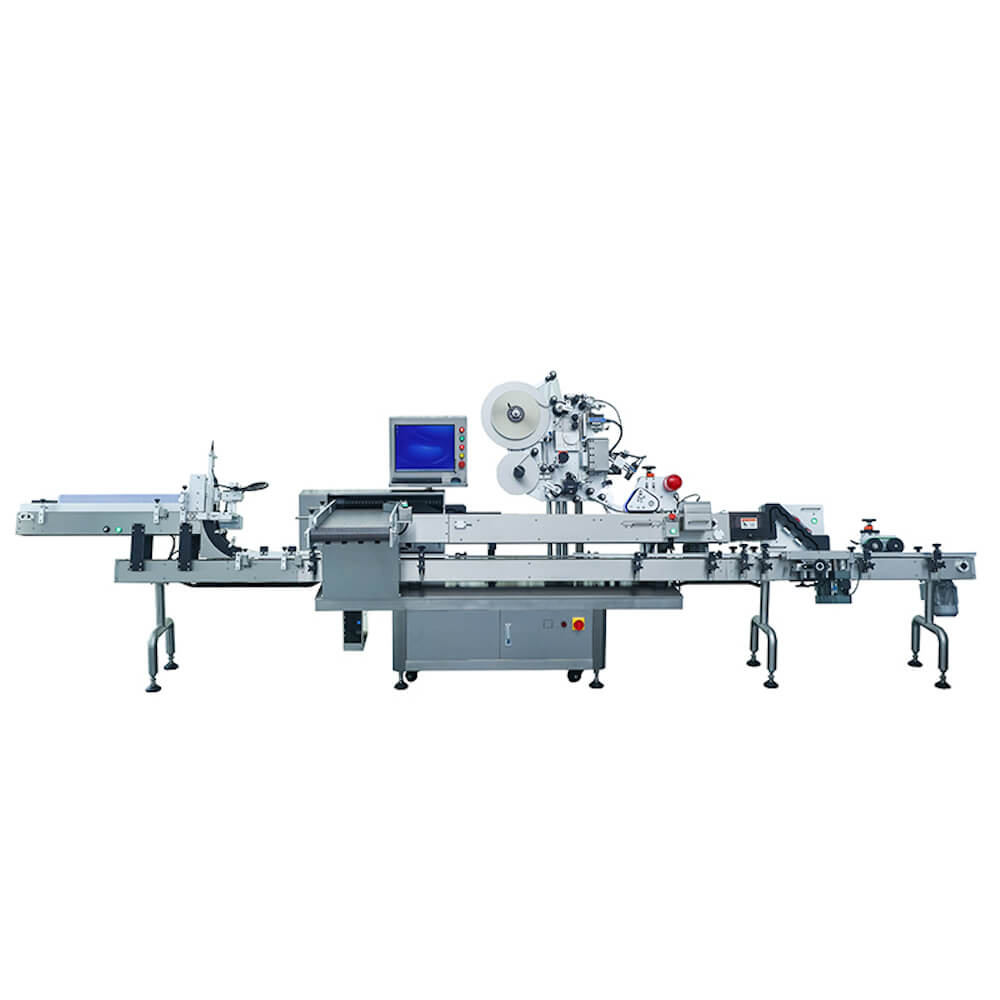

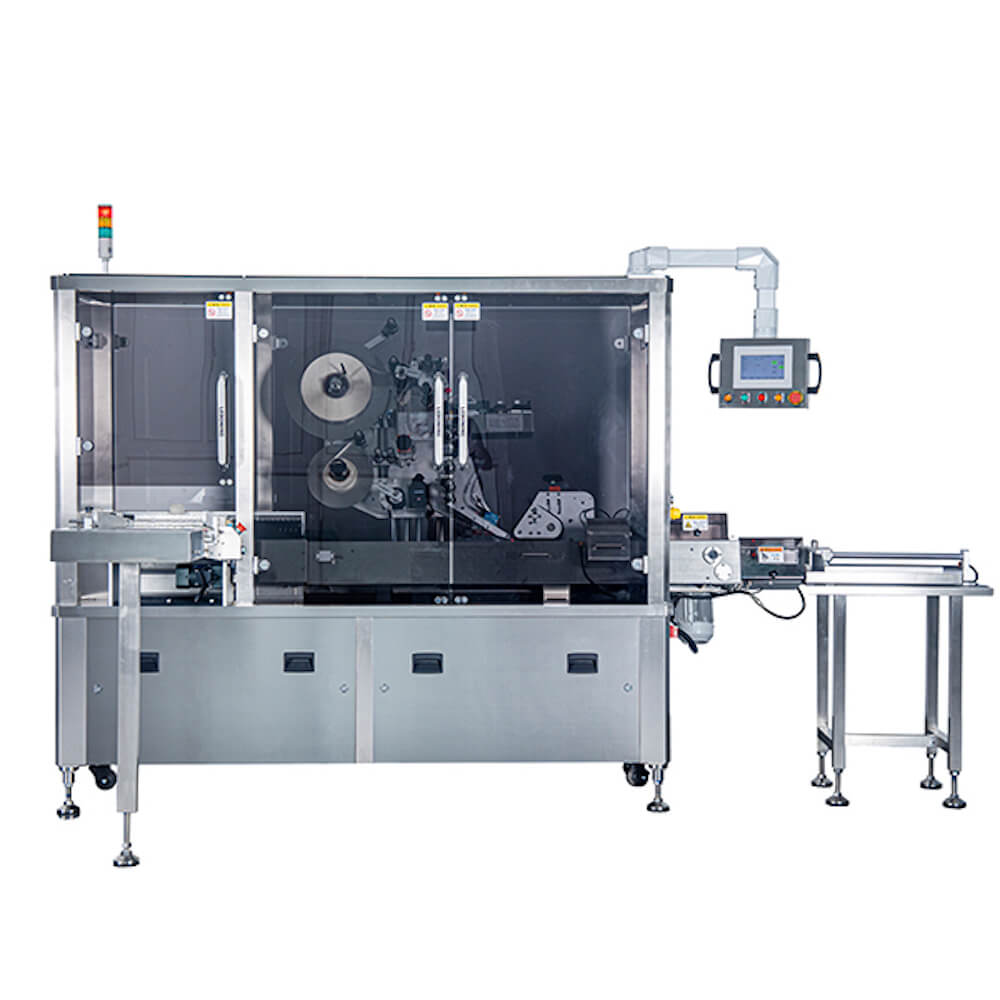

Check these 3 models for horizontal labeling:

Why Choose VialLabller Pharma Labeling Systems?

Our horizontal labeling machines ensure precision and efficiency for cylindrical and irregular containers. Simply provide your container size, label dimensions, and specific application requirements. We can customize the perfect solution for you.

Worldwide Countries Shipped

Years of Marketing Experience

Customer Satisfaction Guaranteed

Precise Horizontal Labeling for Pharmaceutical Containers

Horizontal labeling machines are designed to apply labels on unwieldy round containers. These machines can wrap full or partial labels on non-freestanding cylindrical items such as pens, test tubes, and lipsticks.

Our horizonal systems handle these round pharmaceuticals:

Machine Videos

See our horizontal labeling labeling systems in action, applying labels quickly and accurately on various container sizes and types.

Horizontal Bottle Labeling Machine with Packaging Line for 10ml Vials

Horizontal Labeling Machine for 1ml Ampoules

Horizontal labeling machine for 2 ml ampoules

Horizontal Labeling Machine for 10ml Liquid Bottles | 300pcs/min

Horizontal Labeling Machine for 10ml Vial Bottles | Equip Turntable Feeding System

Horizontal Labeling Machine for 5ml Vial Bottles | Equip Turntable Feeding System

FAQs

- How does a horizontal labeling machine prevent products from colliding and wearing during the labeling process?

The machine uses precision spacing mechanisms and synchronized conveyors to ensure consistent separation and gentle handling.

- How to adjust the horizontal labeling machine to fit different-sized products?

Different sizes and shapes of products can be accommodated by adjusting the position of the conveying machinery and labeling head.

- Can we receive a design drawing customized for our specific factory layout?

Absolutely! We will provide a personalized design drawing crafted by one of our skilled engineers at no additional cost for you to review before finalizing your quote.

- How long does it take to deliver a machine after placing an order?

Delivery times may differ depending on the type of machine and our production schedule, typically ranging from 6 to 8 weeks.

- What payment options are available for purchasing a machine?

We offer several convenient payment methods, including bank transfers, credit cards, and PayPal.

- What support services are offered after purchasing a machine?

We provide continuous online support for any technical or troubleshooting needs throughout the life of your machine, along with parts supply and maintenance services.

- Is there training available for operating and maintaining the machine?

Yes, we offer complimentary online training sessions to help clients learn efficient operation and maintenance of their machines.

- What is the warranty period for your machines?

Each of our machines includes a standard one-year warranty, with options for extended warranties available upon request.

Let’s work together

We’d love to hear from you! Send us a message using the form opposite, or email us. We’d love to hear from you! Send us a message using the form below.