The concept of drug traceability has emerged as a fundamental aspect of modern pharmaceutical regulation, tasked with safeguarding public health by monitoring the life cycle of medications within the pharmaceutical industry.

Ensuring that drugs can be traced from production to consumption assists in preventing counterfeit products from infiltrating the market and guarantees that consumers receive safe and effective medications.

Significance of drug traceability standards in the pharmaceutical supply chain

Drug traceability standards are pivotal in maintaining the integrity of the pharmaceutical supply chain. These standards facilitate tracing prescription drugs, helping to quickly identify and rectify issues such as contamination, incorrect dosages, and distribution of counterfeit medications.

Compliance with traceability requirements ensures that stakeholders, from manufacturers to pharmacies, uphold strict quality controls. This regulatory framework not only protects consumer health but also enhances the credibility of pharmaceutical companies and fosters trust in healthcare systems globally.

Common traceability standards

International standards

The ISO norms serve as a cornerstone in setting comprehensive global expectations for drug quality and safety. These standards are designed to provide a uniform framework that aligns with various national regulations, ensuring that the handling, storage, and transportation of pharmaceutical products meet universally accepted levels of quality and integrity.

These standards are critical in facilitating international trade in pharmaceuticals, ensuring that products crossing borders are consistently safe and effective within complex supply chains.

European Union

The Falsified Medicines Directive (FMD) is a significant regulatory measure implemented by the EU to secure the pharmaceutical supply chain against the infiltration of counterfeit drugs. This directive mandates the serialization of prescription drugs, using a unique identifier for each package, which can be scanned and verified at each point in the supply chain.

Wholesale distributors play a crucial role in complying with the Falsified Medicines Directive by ensuring that all serialized packages are properly tracked and reported throughout the supply chain.

This system enhances traceability, allowing regulators and companies to track the movement of medicines from the manufacturer to the pharmacy, thereby significantly reducing the risk of counterfeit products entering the market.

United States

The Drug Supply Chain Security Act (DSCSA) establishes critical provisions to protect the U.S. drug supply chain. This act requires the implementation of systems that can track prescription drugs as they are distributed across the United States, ensuring enhanced drug distribution security.

By mandating unique identifiers on drug packages, the DSCSA ensures that each transaction involving a drug product is documented, thereby creating a traceable path from the point of manufacture to the point of sale. This traceability is crucial for detecting and removing counterfeit or compromised drug products from the supply chain. Trading partners, including manufacturers and distributors, have significant responsibilities in ensuring compliance with the DSCSA to protect consumers from harmful drugs.

China

In China, regulations such as the “Drug Administration Law” and the “Measures for the Management of Drug Traceability” are essential components of the national strategy to ensure drug safety and efficacy.

These regulations standardize practices across China’s vast market, requiring manufacturers and distributors to establish systems that can accurately trace drug products throughout their lifecycle. Third-party logistics providers play a crucial role in complying with these drug traceability regulations.

By maintaining detailed records of each drug’s production, distribution, and sale, these regulations aim to protect consumers from substandard, counterfeit, or expired medicines and ensure compliance with safety standards.

Key technologies for drug traceability to combat counterfeit drugs

Barcode technology: Allows for quick scanning of drug information at any point in the supply chain.

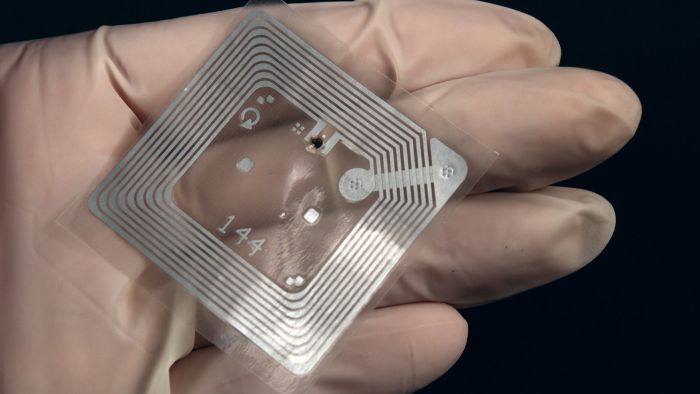

- RFID (Radio-Frequency Identification): Provides wireless tracking of drug packages, enhancing the efficiency of inventory management.

- Database management systems: Centralize data storage, making it easier to retrieve comprehensive tracking information.

- Encryption and data security: Ensure that all transmitted and stored data remains secure from unauthorized access.

The Drug Supply Chain Security Act (DSCSA) mandates the tracking and identification of not only pharmaceuticals but also medical devices, ensuring safety and accountability from production to patient delivery.

The role of labeling

- Facilitates the visualization of important drug information, especially for certain prescription drugs.

- Enhances automatic data collection.

- Improves the accuracy and efficiency of data entry.

Viallabeller offers a wide range of pharmaceutical labeling machines and pharmaceutical labeling solutions, such as pharma box labeling, pill bottle labeling, ampoule labeling, and more.

Main functions of drug traceability systems

- Information collection and record-keeping: Systems meticulously record each transaction associated with the drug’s journey, capturing details such as manufacturing dates, batch numbers, and distribution points. This creates a comprehensive log of the drug’s path from production to the end-user, which is crucial for identifying and preventing the distribution of harmful drugs.

- Data storage and management: Ensure the integrity and accessibility of traceability data throughout the drug’s lifecycle(from medicine manufacturing to selling) by using secure databases and backup systems. This guarantees that data remains accurate and available for auditing or review whenever needed.

- Information sharing and access: Stakeholders, including manufacturers, distributors, and healthcare providers, can access real-time data to verify drug history and authenticity. This transparency helps maintain trust and ensures that everyone involved in the supply chain can confirm the legitimacy of the products they handle.

- Incident reporting and handling: Systems promptly address and manage discrepancies or anomalies in the supply chain by generating alerts and reports. These tools help identify issues quickly, allowing for immediate investigation and resolution to prevent potential harm or regulatory breaches.

- Verification of drug authenticity: Protects against counterfeit drugs by verifying the unique identifiers on each product, ensuring patient safety and regulatory compliance. This process helps confirm that each drug is genuine and has been properly handled throughout its journey.

Conclusion

The deployment of robust drug traceability systems is a testament to the pharmaceutical industry’s commitment to ensuring the safety and efficacy of its products.

Through stringent standards and innovative technologies, these systems uphold the health of individuals and the integrity of global healthcare practices. Drug traceability ensures not only compliance with legal mandates but also supports the critical task of delivering safe, effective, and high-quality medications to consumers worldwide.