Choosing the right vial size is essential for the efficiency and success of applications in various fields such as pharmaceuticals and cosmetics.

This comprehensive guide will delve into the different types of vials, including amber glass and borosilicate glass, their sizes, and how to select the appropriate size based on specific requirements.

Types and structures of vials

Vials come in various materials, each serving distinct purposes:

- Glass vials: Preferred for medical and laboratory applications due to their chemical resistance and ability to preserve substances. Amber glass vials are particularly beneficial for protecting sensitive samples from harmful light exposure.

- Plastic vials: Used widely for their light weight and break resistance, suitable for general consumer products. Clear glass vials provide an unobstructed view of solutions, making them ideal for analysis purposes.

- Metal vials: Often chosen for their durability and unique protection against light, used in specialized fields. The use of inert materials in vials is crucial for storing solvents and samples to ensure chemical compatibility and resistance to solvent vapors.

Each material offers different advantages depending on the intended use, which should guide the size selection.

Standard vial sizes

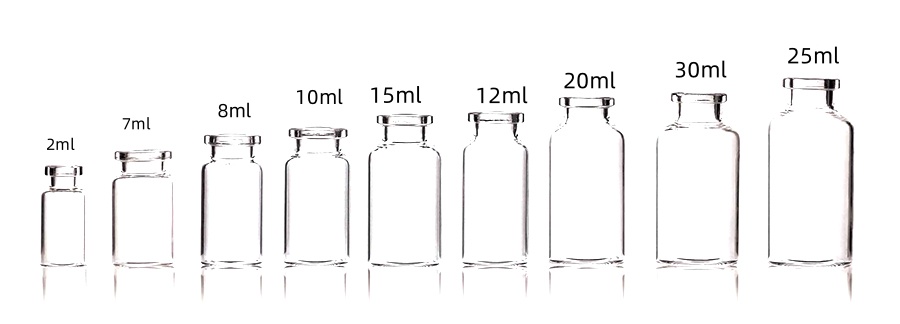

Vial sizes vary, with common capacities ranging from 1ml to 20ml. Understanding the standard sizes available helps in planning and usage:

- Small vials (1-5ml): Used for high-potency medications where dosages are minimal.

- Medium vials (5-10ml): Often used for vaccines or injectables.

- Large vials (10ml+): Best for products that require larger doses or multi-user scenarios.

It is important to note that the diameter of the vial’s screw thread closure is crucial for ensuring compatibility and sealing effectiveness.

The choice of vial size should also consider the handling and storage logistics, ensuring that the vials fit well with other equipment like auto-injectors or storage trays. Additionally, a flat bottom design is recommended for stability and specific applications like freeze drying.

Considerations for choosing vial size

Selecting the right vial size involves several factors:

- Content properties: Viscosity and chemical composition can dictate the choice of size and material. Different cap types, such as crimp, snap, and screw finishes, play a crucial role in ensuring secure storage and preventing containment issues.

- Usage requirements: Whether the product needs to be dispensed in controlled amounts or stored for extended periods can affect the size. The dimensions of the vials are also important for ensuring compatibility with robotic machines and autosamplers.

- Safety and portability: Ensuring the vials are secure and easy to transport without leaks is crucial.

The impact of vial size on drug stability

The relationship between capacity and drug stability

The size of a vial can affect how stable a drug is. When a drug is stored in a vial, the amount of space inside can influence how well the drug stays effective. For example, if a vial is too large for a small amount of liquid, the extra air inside can cause the drug to break down faster. On the other hand, a vial that is just the right size helps keep the drug stable for a longer time.

The effect of vial size on drug expiration dates

Vial size also plays a role in how long a drug can be used before it expires. A smaller vial may help keep the drug fresh because it limits exposure to air and light. This means that drugs in smaller vials might last longer than those in larger vials.

Understanding how vial size affects expiration dates is important for both manufacturers and users to ensure that medications remain safe and effective.

Market trends in vial sizes

Current trends in vial sizes

The market for vials is changing. Many companies are looking for new ways to improve their products. This includes creating vials in different sizes to meet the needs of various drugs.

For example, as new medications are developed, the demand for specific vial sizes may increase. Companies are paying attention to these trends to stay competitive.

The impact of emerging technologies on vial design

New technologies are also influencing how vials are designed. Innovations in materials and manufacturing processes allow for the creation of vials that are lighter, stronger, and more efficient. For instance, some companies are developing vials that can better protect drugs from light and air.

These advancements help ensure that medications remain stable and effective for longer periods. As technology continues to evolve, we can expect to see even more changes in vial sizes and designs in the future.

Conclusion

Choosing the right vial size is not just about fitting the content—it’s about ensuring the overall integrity and usability of the product. From pharmaceuticals to skincare products, the correct vial size enhances the product’s functionality and user satisfaction.

By understanding the various factors involved in vial size selection, industries can make informed decisions that optimize both cost and performance. However, different vial sizes will also correspond to different labeling needs. We provide a series of solutions, you can read…