In the pharmaceutical industry, the accuracy and efficiency of vial labeling are paramount. As regulations tighten and production demands increase, the technology behind vial labeling machines and their labeling system has evolved significantly. An effective vial labeling system is crucial for ensuring accurate identification and tracking of vials, reducing the risk of costly errors.

This guide explores the cutting-edge technologies currently available in vial labeling machines, highlighting their features, applications, and the regulatory standards they help manufacturers meet.

Overview of vial labeling system

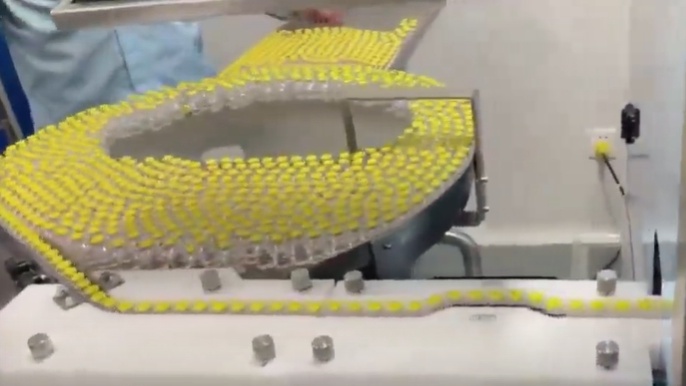

Labeling machines for vials apply labels on vials accurately and quickly, a critical task in pharmaceutical packaging. Labeling vials requires precision to avoid errors, especially for all-around labeling that must prevent spinal misalignment. These machines must handle various vial sizes and materials while ensuring that labels are applied without bubbles, or wrinkles, and in the correct orientation.

Technical features of vial labeling machines

- Automation levels: Modern vial labeling machines offer varying levels of automation, from semi-automatic models for small-scale operations to fully automated systems for high-volume production.

- Precision and speed: These machines are engineered to maximize output without compromising the accuracy of label placement, capable of handling hundreds, if not thousands, of vials per minute.

- User interfaces: Advanced touchscreen interfaces facilitate ease of use, allowing operators to adjust settings quickly and monitor the labeling process in real-time.

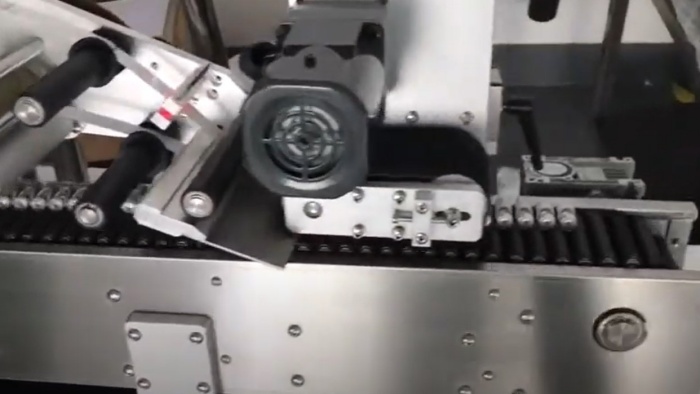

- Thermal transfer printer ability: These labeling systems are equipped with thermal transfer printers, which efficiently manage various label formats and information on small pharmaceutical containers, ensuring compatibility with different vial types.

Vial labeling requirements

- Label content and size: Regulatory bodies require that vial labels contain specific information such as drug name, dosage, expiration date, and batch data. The machines must accommodate different label sizes and materials, adjusting to meet these content requirements.

- Application techniques: Labels must be applied securely to ensure they remain intact under various storage conditions. Technologies like wrap-around labeling are common in meeting these needs.

- Variable data: In the pharmaceutical industry, it is crucial to print variable data on labels and vials. This includes ensuring the durability of printed information such as serial and batch numbers, and accommodating rapid changes in labeling requirements while maintaining printing quality.

Applications in the pharmaceutical industry

Vial labeling machines are crucial in environments where sterility and precision are non-negotiable. These machines are compatible with cryo vials, ensuring efficient labeling for cryogenic sample management in laboratories. They are used extensively not only in pharmaceuticals but also in biotechnology and cosmetic industries, wherever vials are a primary packaging solution. Additionally, specific equipment is designed to quickly and accurately apply labels to PCR tubes, which are essential in pharmaceutical and diagnostic applications.

Innovative technologies in vial labeling

- Vision inspection systems: Many vial labeling machines now incorporate sophisticated cameras and image processing software to inspect labels for accuracy and presence immediately after application.

- Integrated printing technologies: To comply with track-and-trace regulations, some vial labelers come equipped with printing capabilities that include batch numbers and barcodes directly on the labels.

- Adjustable labeling heads: For flexibility, labeling heads can be adjusted to handle various vial sizes and shapes, ensuring consistent label application across different product lines.

- Booklet labels: Booklet labels are a vital solution for situations requiring extensive information on vials. They are particularly useful when products need to convey information in multiple languages or when there is a significant amount of documentation that must accompany the product, ensuring compliance and clarity in diverse markets.

- Documentation labels: Documentation labels, often in the form of booklet labels, are crucial for conveying extensive information in multiple languages for pharmaceutical products. They ensure compliance and provide essential details, especially when products are distributed internationally.

Challenges in vial labeling

Despite technological advances, challenges remain:

- High-speed production: Maintaining labeling accuracy at high speeds is a persistent challenge, requiring constant innovation in machine design and control systems to ensure reliable labeling.

- Diverse vial designs: The variety of vial sizes and shapes necessitates versatile machines that can quickly adapt to new specifications without extensive downtime for setup changes.

Future trends in vial labeling technology

The future of vial labeling is likely to see more integration of AI and machine learning to further enhance the precision and adaptability of labeling machines. These advancements will cater to vials ranging in size, ensuring efficient and customized labeling solutions. These technologies can predict and adjust to variability in production lines in real time, increasing both efficiency and accuracy.

Conclusion

As the demand for more efficient and compliant pharmaceutical packaging continues to grow, the technology behind vial labeling machines is rapidly evolving to meet these needs.

With advancements in automation, precision, and integration capabilities, vial labeling machines are set to become even more indispensable in the pharmaceutical industry. These machines are crucial for accurately labeling vials containing liquid substances, including vaccines and other medicines, to avoid costly errors and ensure public safety.

Manufacturers must stay abreast of these technological trends to ensure their operations remain compliant and competitive in a fast-evolving market.