In the pharmaceutical industry, tamper-evident labeling plays a crucial role in ensuring the safety and integrity of medical products. As counterfeiting and tampering attempts have become more sophisticated, the need for robust security measures has intensified.

Tamper-evident labels not only serve to deter tampering but also provide a clear indication if interference has occurred, thereby protecting consumer trust and compliance with regulatory standards. Additionally, these labels reinforce brand integrity by ensuring that products remain authentic and secure for consumers.

Definitions and objectives

Tamper-evident labeling refers to security labels that provide tamper evidence by showing visible signs of tampering when an attempt is made to remove or alter them. The primary objective of these labels is to safeguard the authenticity and quality of the product by preventing unauthorized access to the contents of pharmaceutical packaging.

They are designed to disintegrate, leave residues, or indicate tampering through visible damage, ensuring that any unauthorized attempts are immediately noticeable.

Types of tamper-evident labels

- Destructive labels: These labels are designed to tear or break if someone attempts to remove them from the product packaging. Made from fragile materials, the labels fragment into pieces, making it impossible to reapply them without visible evidence of tampering.

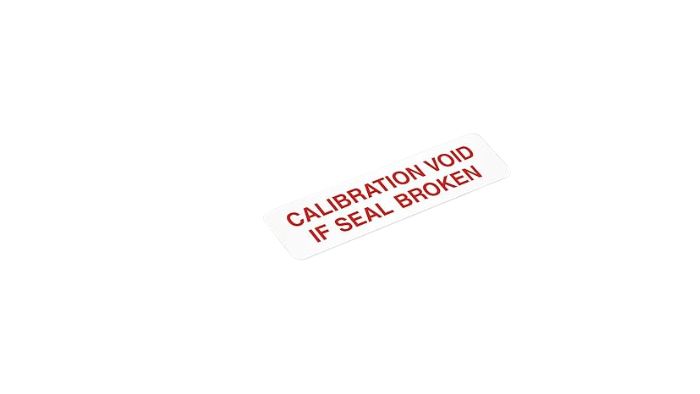

- Void labels: Void labels, also known as evident void labels, leave a sticky residue or a pattern (typically the word “VOID”) on both the label and the product surface when removed. This residue indicates that the label has been tampered with and cannot be restored to its original state without visible signs. Tamper-evident void labels serve as a protective measure to ensure that consumers are aware if a package has been compromised.

- RFID tags: Radio Frequency Identification (RFID) tags are used for more than just tracking; they can be integrated into tamper-evident systems. These tags can alert manufacturers and distributors to unauthorized access to the products by transmitting data on their status and location.

- Digital seals: Incorporating blockchain and other digital technologies, digital seals offer a more advanced level of security. These seals provide a tamper-proof digital record of the product’s journey from manufacture to sale, ensuring the product’s history is transparent and unalterable.

Applications in the pharmaceutical industry

- Packaging security: Tamper-evident labels are extensively used in pharmaceutical packaging to prevent unauthorized opening. By securing the outer packaging of medicines, they ensure that the product reaches the consumer exactly as it left the production facility. Tamper-evident labels are also crucial in secondary packaging to enhance product safety and integrity. Additionally, the use of tamper-evident materials specifically designed for pharmaceutical packages is growing, as they maintain product integrity without leaving residue upon removal. The importance of tamper-evident labels extends to medical devices, ensuring their integrity and safety for consumers and patients. Furthermore, the versatility and customization options of tamper-evident folding carton seals allow for various shapes and sizes, integrating seamlessly with labeling machinery for precise application.

- Logistics and tracking: During transportation and storage, tamper-evident labels help maintain a secure supply chain. They allow companies to monitor their products throughout the distribution process, ensuring that the products are not tampered with during transit.

- Regulatory compliance: Many health and safety regulations require the use of tamper-evident labels to meet industry standards. These labels help pharmaceutical companies comply with laws that aim to protect consumers from counterfeit and tampered-with products.

Future trends and challenges

The integration of IoT (Internet of Things) and AI (artificial intelligence) technologies into tamper-evident labeling solutions is set to revolutionize the industry.

Tamper-evident solutions provide secure packaging options across various industries, particularly focusing on pharmaceutical applications. These solutions include shrink sleeves and tamper-evident tapes, designed to enhance security and branding for manufacturers.

These technologies can enhance the functionality of tamper-evident labels by enabling real-time monitoring and data analytics, which can predict and prevent tampering incidents before they occur.

However, the adoption of these advanced technologies comes with challenges such as increased costs, the need for technological upgrades, and concerns about data privacy. The industry must address these challenges to fully realize the benefits of next-generation tamper-evident labeling solutions.

Conclusion

As the pharmaceutical industry continues to battle against the risks of product tampering and counterfeiting, the role of tamper-evident labeling becomes increasingly vital. These labeling solutions not only deter tampering attempts but also ensure that any such attempts are immediately evident, thus maintaining the integrity of the pharmaceutical supply chain.

Tamper-evident packaging plays a critical role in ensuring the safety and quality of products, particularly pharmaceuticals and food items. An intact seal indicates security, whereas a broken seal signals potential tampering and triggers an alert, emphasizing the importance of monitoring product integrity.

As we move forward, the industry’s focus must remain on advancing these technologies to provide even greater security and assurance to consumers worldwide. This commitment to enhancing tamper-evident labeling is essential for protecting public health and upholding the trust that consumers place in pharmaceutical products.

Viallabeller, a company that specializes in manufacturing labeling equipment for the pharmaceutical industry, also has tamper-evident labeling solutions for various pharmaceutical packaging. In addition to this solution, we also have syringe labeling solutions, and vial labeling solutions…