Characterized by its crucial role in safeguarding medications, tamper-evident packaging provides essential tamper evidence to ensure product integrity.

Let’s delve into the significance of tamper-evident packaging, its profound impact on the pharmaceutical industry, and the innovative solutions offered by leaders in packaging technology.

The types of tamper-evident packaging

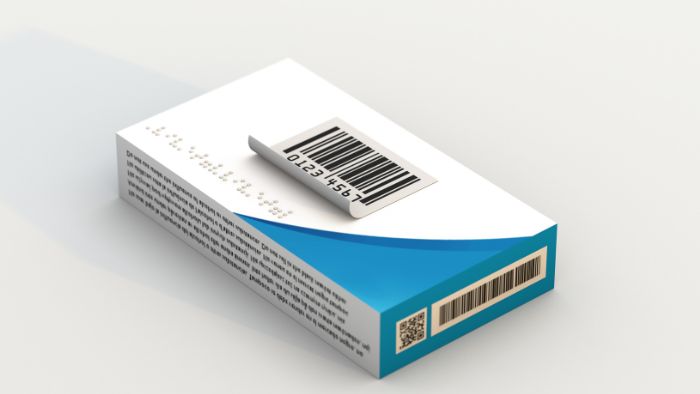

Tamper-evident packaging serves a vital role in the pharmaceutical industry by providing unmistakable evidence of any unauthorized access or tampering with products. This safeguard is crucial for maintaining the safety and efficacy of medications, where even minor tampering can lead to severe consequences for patient health. Examples of tamper-evident packaging materials include:

- Induction seals: These seals are applied to containers like bottles or jars and provide visual evidence of tampering by breaking upon opening, ensuring the integrity of liquid medications.

- Tear tapes: Often found on cartons or boxes, tear tapes reveal if the packaging has been compromised, protecting items like tablets or capsules from potential contamination.

- Embedded QR codes: Utilized increasingly, these codes can be scanned to verify authenticity, ensuring that pharmaceuticals have not been altered or replaced.

- Tamper-evident seals: These seals act as a barrier to entry and provide clear evidence of tampering, reassuring consumers about the product’s integrity.

- Tamper evident tapes: These tapes feature patterns that misalign if the package has been opened, and some variants leave a permanent mark or message on the box when removed.

Why are tamper-evident packages crucial in pharmaceuticals?

- Safety assurance: It guarantees consumers that the product remains intact, reinforcing trust in medication safety. Additionally, child-resistant packaging is crucial for protecting potentially harmful contents, particularly for medications and supplements.

- Regulatory compliance: Many health authorities enforce tamper-evident features for specific pharmaceuticals to ensure patient safety. The Poison Prevention Packaging Act mandates child-resistant packaging for certain medications and household products to prevent accidental ingestion by children.

- Brand protection: Tamper-evident labeling preserves brand integrity, fostering consumer confidence and loyalty.

- Counterfeit deterrence: It complicates replication and tampering efforts, thereby shielding end consumers from counterfeit risks.

What is the impact of tamper-evident packaging on the pharmaceutical industry?

- Enhancing patient safety: Discouraging tampering ensures medication safety and efficacy. Tamper-evident packaging also plays a crucial role in ensuring product integrity throughout the supply chain, benefiting manufacturers, retailers, and consumers.

- Building consumer trust: Brands demonstrating a commitment to safety are more likely to earn and retain consumer loyalty. Resistant packaging is designed to prevent unauthorized access to products, providing an additional layer of security.

- Regulatory compliance: It assists pharmaceutical companies in adhering to stringent regulations, averting potential legal repercussions.

- Innovative brand image: Companies adopting advanced tamper-evident technologies are perceived as industry leaders and pioneers.

The role of labeling machines in tamper-evident packaging

Labeling machines play a crucial role in ensuring the integrity of anti-tamper packaging by securely affixing tamper-evident labels onto products.

Tamper-resistant packaging is designed to prevent access to the contents and provide visible evidence if tampering occurs, ensuring consumer safety and confidence.

These machines apply labels with precision and consistency, featuring tamper-proof mechanisms that provide visible evidence of any attempt to open or manipulate the packaging.

By effectively sealing products with tamper-evident labels, labeling machines deter unauthorized access and safeguard the contents from tampering or contamination.

This process enhances consumer trust and product safety, meeting regulatory requirements for tamper-proof packaging in pharma industries. If you want to choose a good labeling machine to prepare for tamper-resistant labeling, Viallabeller’s pharmaceutical labeling machines offer tamper-evident labeling solutions.

Conclusion

Tamper-evident packaging stands as an indispensable safeguard in pharmaceuticals, ensuring product integrity and consumer safety by providing visible evidence of tampering.

By deploying advanced technologies like tamper-evident labeling solutions from Viallabeller, pharmaceutical companies enhance trust, comply with regulations, and protect against tampering, reinforcing their commitment to safety and quality assurance.