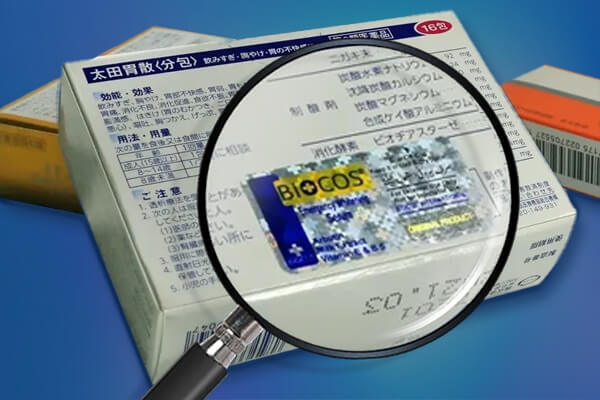

Tamper Evident Labeling Machine

Worried about product tampering? Secure your brand with VialLabeller tamper evident labeling machines. Help you to apply safety labels on boxes. Protect your brand and gain consumer trust today.

- Tailored for an array of product shapes

- Exceptional labeling speed and accuracy

- Over 99.9% labeling success rate

- Seamless integration and customization

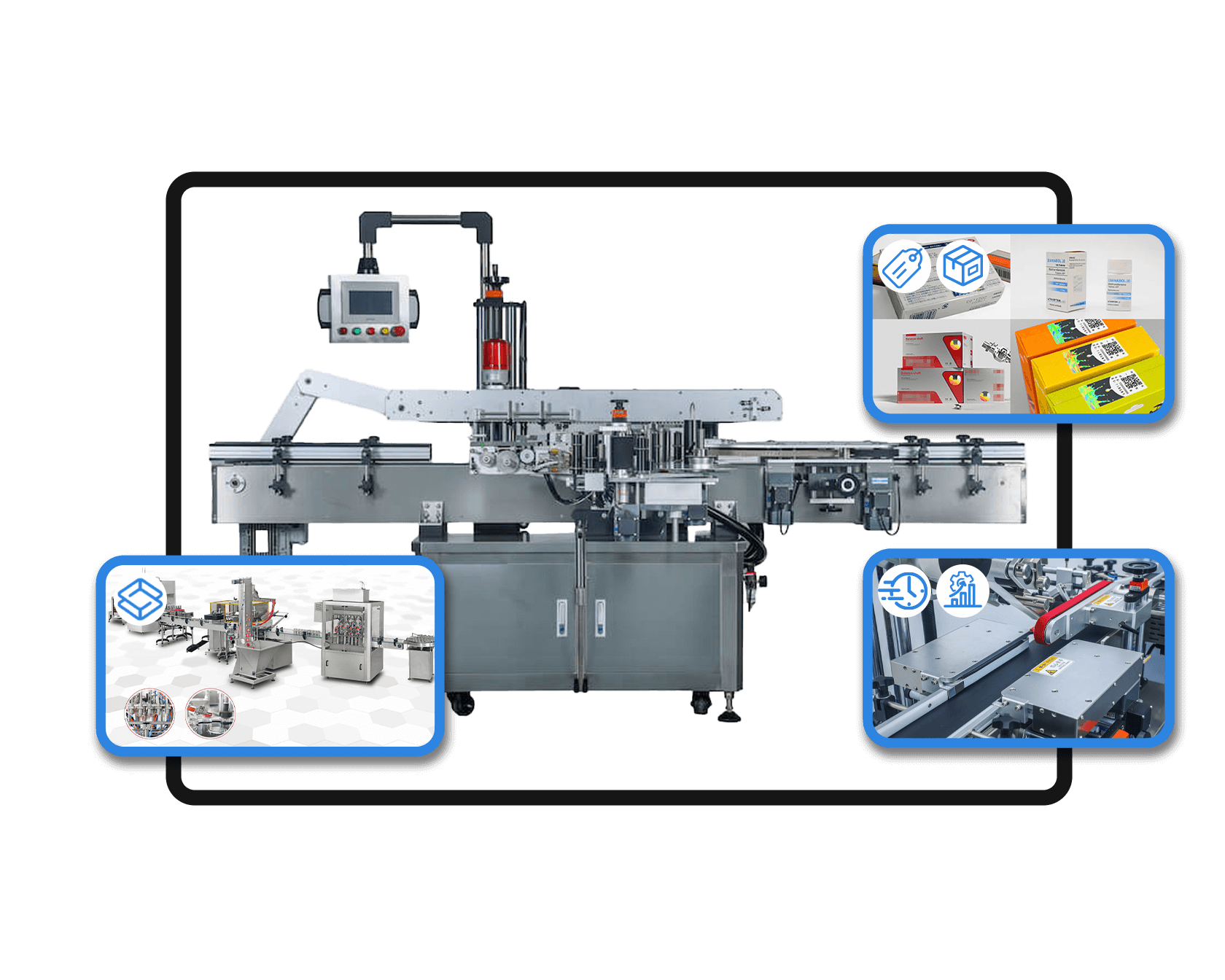

Featured Machinery

VialLabeller offers automated systems for labeling on box and cartons. Help you speed up to labeling and reduce labor cost. Check machines below:

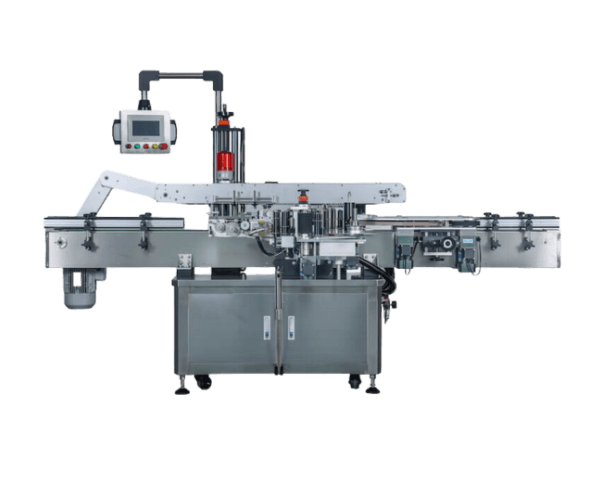

High Speed Tamper Sticker Labeler for Box Safety

The P-280 is a super fast machine for tamper evidence labels. It can put labels on both sides of special medicine boxes very accurately.

Features

- Handle up to 300 boxes per minutes.

- Handles paper labels and transparent labels

- The spring buffer pressing mechanism , combined with the conveyor belt, keeps containers steady during labeling.

- The machine uses servo motors for power, ensuring fast and accurate labeling.

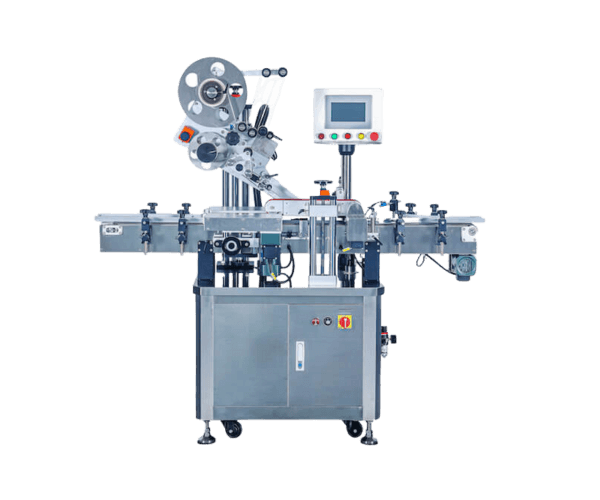

Small Box Corner Wrap Labeling Machine

The P-260 upgrade based on P-280 model. Specifically designed for corner-wrap labeling on box 2 adjacent faces.

Features

- Speed up to 150 boxes per minute accurately.

- Features a box separation and correction mechanism for different product sizes.

- Servo motor and PLC control label peel, no manual adjustments.

- Alerts and auto-stops for label issues or no boxes(missing labels, label breaks, or low ribbon).

Tamper Evident Labeling System with Protect Cover

System type: Corner case labeler, anti-tamper labeler

Applicable box types: boxes(smaller cartons)

This labeling system is upgrade based on P-260. Equip with protect cover for human safety.

Why Choose VialLabeller Labeling Systems for Safety Labels?

Our systems improve packaging by using new technology and customizable features. Ensure precise, fast service to improve your packaging efficiency. Our support team, including engineers, is here to help. We work to improve your labeling process.

Worldwide Countries Shipped

Years of Marketing Experience

Customer Satisfaction Guaranteed

Machine Videos

See how to apply tamper-evident security labels on prescription medicines with our machines. And how we ensure precise label placement on these box/carton sizes when pharmaceutical manufacturing.

Box corner labeling machine video

Corner Labeling Machine for Packaging Boxes Video

Let’s work together

We’d love to hear from you! Send us a message using the form opposite, or email us. We’d love to hear from you! Send us a message using the form below.