Quick-release mechanisms are used in many tools and machines today. They let people join and take apart parts fast and safely. These systems help things work better in different areas.

This guide will show how these systems work, where they are used, and what is coming next for them.

Fundamental principles of quick-release mechanisms

Quick-release mechanisms let people quickly connect and remove parts without tools.

They have a few main parts like latches, pins, or magnetic locks. These parts work together to keep everything securely in place.

Operating principles

The key principles for using quick-release mechanisms include:

- Check that all parts are in the correct position before locking.

- Apply one simple action to secure or release the parts.

- Make sure the locking system stays strong and does not slip.

- Use quick-release mechanisms in areas where speed and convenience matter.

- Regularly inspect the parts to ensure they are working properly.

By following these steps, people can use quick-release mechanisms safely and effectively in many different fields.

Common types

- Mechanical quick-release: This includes buckles, knobs, and locking pins. These parts use force to connect and release. Locking pins are very important because they keep things secure and are easy to use. They also help protect against theft.

- Magnetic quick-release: This system uses magnets to hold parts together. It makes it easy to disconnect when needed.

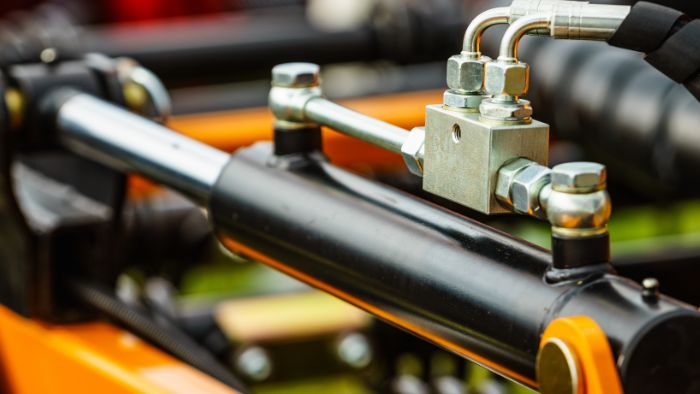

- Pneumatic or hydraulic quick-release: These systems use air or fluid pressure to connect and disconnect parts. They are often used in large machines in factories.

Applications of quick-release mechanisms

Outdoor and sports equipment

Quick-release systems are used in gear like ski bindings and climbing tools. These systems help set up equipment fast and take it apart quickly. This keeps people safe by saving time and making the process easier. Whether skiing or climbing, quick-release systems help athletes stay focused on safety.

Industrial use

In factories, quick-release systems help with quick repairs and part changes. Workers can fix machines faster, which saves time and keeps things running smoothly. These systems work with many different machines, making them useful for different jobs. This helps workers focus on keeping production going.

Automotive and cycling

In cars and bikes, quick-release systems are used for wheels, seats, and other parts. Since these parts need to be adjusted often, quick-release systems make it easy to make changes without tools. It’s important to have the right size to keep everything safe.

Medical devices

In hospitals, quick-release systems make medical tools easier to use and clean. This is important when parts need to be changed quickly to keep patients and doctors safe.

As a maker of pharmaceutical labeling machines, Viallabeller uses the systems in many machines, including those for horizontal labeling and wrap-around labeling.

Advantages and challenges of quick-release mechanisms

Advantages

- Quick-release systems help speed up work by allowing fast connections.

- They do not need tools to attach or remove parts.

- These systems are easy to use and make repairs simpler.

- They are good for both professional and everyday use.

Challenges

A big challenge with quick-release systems is how long they last.

Using them a lot can cause wear and breakage if they are not strong enough. It is very important to keep these systems safe and reliable.

If they fail, people can get hurt or equipment can break. Always follow the weight limits for these systems to avoid problems.

Trends in quick-release mechanisms

Smart technology integration

The future of quick-release systems will use smart technology like sensors and automated controls. These will give real-time updates and allow remote control. Quick access will help make work faster in many industries.

Material innovation

New materials are being made that are stronger and lighter. This helps quick-release systems last longer and work better in different conditions.

Multi-functionality

Quick-release systems are being designed to do more than one job. This makes them more useful in different places. These systems allow fast part changes and strong connections, especially in factories and packaging.

Conclusion

In summary, quick-release systems are important in many areas. They are used in machines, sports gear, and medical tools. They help make fast, easy, and safe connections. This makes them very useful in many jobs.

As technology grows, quick-release systems will become even better. They will have smarter features and new designs. These changes will help them stay fast and easy to use.