Drug-making process should use pharmaceutical equipment. They help speed up different production tasks.

Solid dose and liquid drugs both need special machines. These machines handle each step of making medicine. Next, you will learn about the different machines used to make drugs.

Pharmaceutical processing equipment and their functions

Agitators

Mix liquids, help with reactions, and move heat or cold.

Blowers

Help recover solvents and support evaporation in making medicine.

Boilers

Make steam by heating water for cleaning and heating tasks.

Capsule equipment

Fill, polish, and sort capsules for correct doses.

Capsule and tablet printers

Print drug names and dosages on pills.

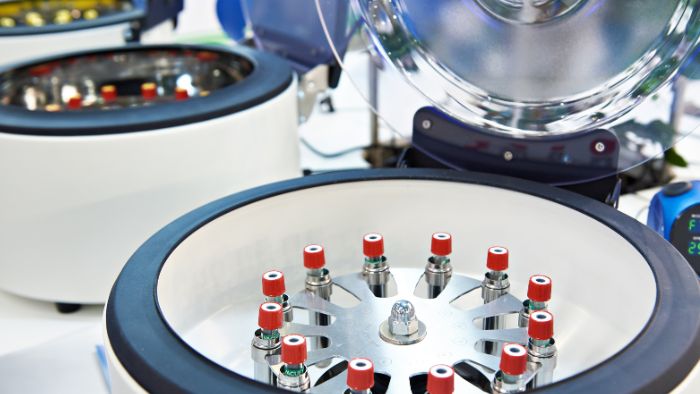

Centrifuges

Separate liquids or remove liquids from solids for purity.

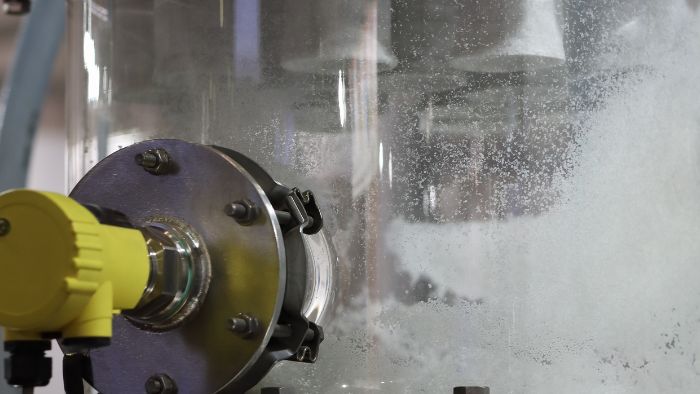

Chillers

Quickly cool things down during medicine making.

Coaters

Add coatings to tablets or capsules for taste and look.

Cooling towers

Cool liquids or steam for controlled temperatures.

Dryers and granulators

Turn liquids into powders or granules.

Heat exchangers

Transfer heat between different materials.

High-pressure homogenizers

Make particles smaller and break cells.

Inspection machines

Check products for quality as they move.

Metal detectors

Find and remove metal bits from products.

Mixers

Blend ingredients and make them uniform.

Ovens

Provide heat to dry and sterilize products.

Pulverizers / Cone mills

Reduce the size of granules.

Tablet presses

Compress powders into tablets of exact sizes.

Tablet deduster

Removes dust and smooths tablet surfaces.

Sifters

Sort powders and granules by size.

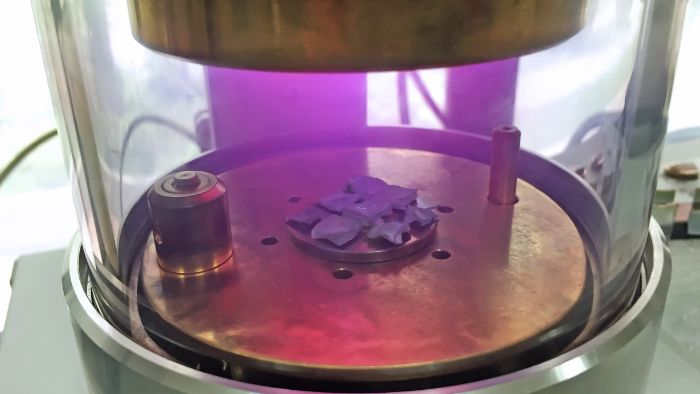

Spray coating machines

Apply coatings to powders for better stability.

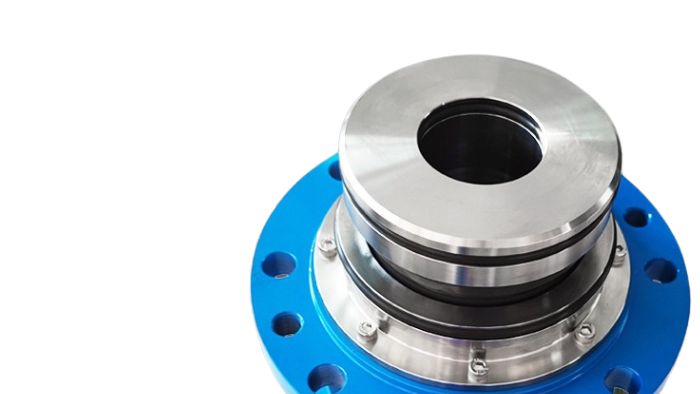

Tanks

Store and handle liquids used in manufacturing.

Primary and secondary packaging equipment and their functions

Blister packers

Package tablets and capsules into blister packs.

Deblistering machines

Recover contents for reuse or repackaging.

Bottling and filling lines

Fill bottles with liquids or tablets.

Cappers

Place caps securely on filled bottles and containers.

Cartoners

Fill medicine boxes, fold leaflets, and seal boxes.

Counters

Count and verify capsules and tablets accurately.

Induction sealers

Seal aluminum foil onto bottle mouths.

Labeling equipment

Attach or print labels on boxes, bottles, and tubes. Viallabeller offers horizontal labeling solutions and wrap-around labeling solutions.

Tube fillers

Fill and seal tubes with ointments and gels.

Sterilization and automatic visual inspection equipment

Autoclaves

Sterilize equipment and containers with high-pressure steam.

Sterile filling machines

Fill sterile products into containers under clean conditions.

Tunnel sterilizers

Sterilize containers and packaging with heat or chemicals.

Conclusion

Pharmaceutical equipment supports precise manufacturing processes. It helps keep product quality and safety. Optimizing production in pharmaceutical manufacturing improves product quality and efficiency.