Pharma anti-counterfeiting measures are very important in today’s world of medicines. Many fake medicines are being made, which can be dangerous.

It’s really important to make sure medicines are safe. That’s why companies and governments are working hard to stop fake medicines.

Fake medicines are bad for people’s health and can make people not trust real medicine companies. In this article, we will talk about different ways to stop fake medicines.

Overview of anti-counterfeiting technologies for counterfeit drugs

The fight against fake drugs uses many methods. These include anti-counterfeiting technologies to check if drugs are real. Some common methods are:

- Fluorescent anti-counterfeiting: Special inks are used that glow under UV light. These inks print hidden marks on packaging. They can be seen with UV light but are invisible in normal light.

- Watermark anti-counterfeiting: Watermarks, like the ones in money, are put into packaging materials. These are hard to copy and easy to check under light.

- Laser holograms: Holograms are secure because they are hard to make. They allow people to see and feel something that is hard to fake.

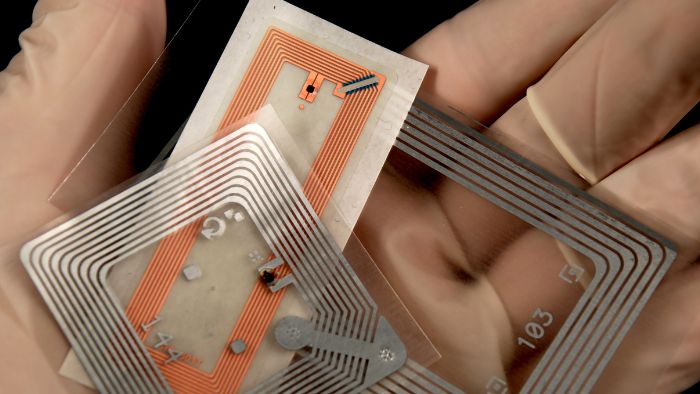

- RFID tags: RFID tags hold data that can be read remotely. These tags are placed in packaging and store details about where the product came from and how it was made.

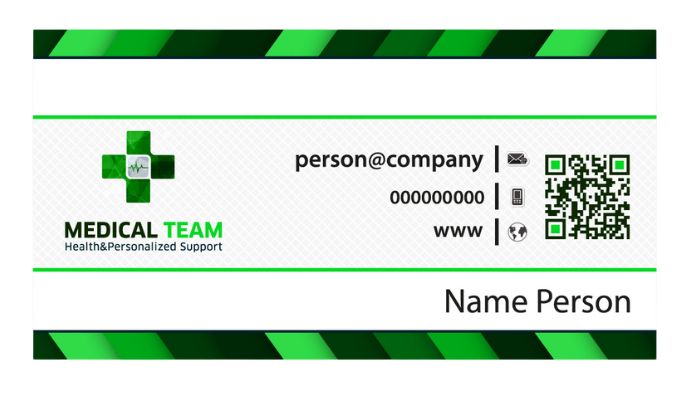

- QR codes: Quick Response (QR) codes are two-dimensional barcodes. They can store a lot of data. Scanning the QR code with a smartphone or other reader can quickly check if the product is real.

Application of anti-counterfeiting labels and tamper evident packaging

Anti-counterfeiting labels are important for protecting pharmaceutical products. Fake packaging can trick people and harm public health. Anti-counterfeiting labels use different technologies:

Types of anti-counterfeiting labels:

- holographic labels

- tamper-evident labels

- security seals

The production process of anti-counterfeiting labels: These labels are made with advanced printing and security features. This process makes the labels strong, unique, and hard to copy.

Verification methods for anti-counterfeiting labels:

- Check these labels with special tools, like UV lights or RFID readers.

- Check with a smartphone using QR codes.

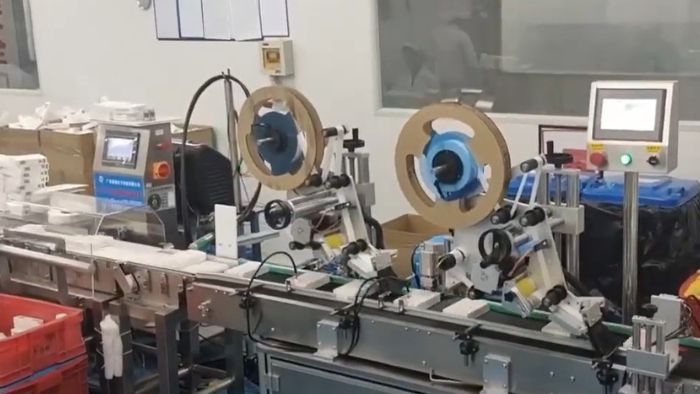

The importance of labeling machines in pharma anti-counterfeiting supply chain

Labeling machines are important in stopping fake products. They make sure every product is labeled with security features. The importance of labeling machines includes:

- Precision and consistency: Labeling machines label each package with precision. This reduces human mistakes and makes sure all products look the same.

- Efficiency: These machines improve production speed. They help companies meet high demands without losing security.

- Traceability: Labeling machines can work with anti-counterfeiting systems. They track and record each product. This helps find fake drugs in the supply chain.

- Flexibility: Modern labeling machines can handle different sizes and shapes. They can be easily adjusted for different types of anti-counterfeiting labels.

- Safety: Advanced labeling machines have inspection systems. They check that all labels are correct. Only properly labeled products leave the factory.

Our pharmaceutical labeling machines meet all of these requirements and also have a range of solutions, such as pill carton labeling solutions and tamper-evident labeling solutions.

Challenges and solutions to implementing pharma anti-counterfeiting measures

Stopping fake medicines is hard. There are a few big problems:

- It costs a lot of money: Making new ways to stop fake medicines is expensive. But it’s important to keep people safe from bad drugs.

- It’s hard to change how things are made: Adding new technology to medicine factories is difficult and needs special skills. We need to keep learning new things and finding better ways to do it.

- Different countries have different rules: Following all the rules from different countries is hard. We need to work together to make one set of rules. For example, the U.S. has a law that makes it harder to sell fake medicines.

- People need to know what to look for: We need to teach people how to tell if their medicine is real or fake. We can do this with special tools and information.

Conclusion

Pharma anti-counterfeiting measures are really important. Fake medicines are dangerous, so we need to make sure all medicines are real.

Special machines can help us do this. These machines put labels on medicine bottles. The labels have special things on them, like colorful inks or tiny chips. This helps us know if the medicine is real.

It’s not easy to stop fake medicines, but it’s very important. We need to keep working to make sure all medicines are safe.