The utilization of label material serves not only to facilitate identification but also to convey crucial information and warnings.

Below is a compilation of 8 commonly employed materials in industrial settings, vital for ensuring effective communication and safety protocols.

Selecting the right label material is essential for various applications, ensuring durability, sustainability, and design flexibility.

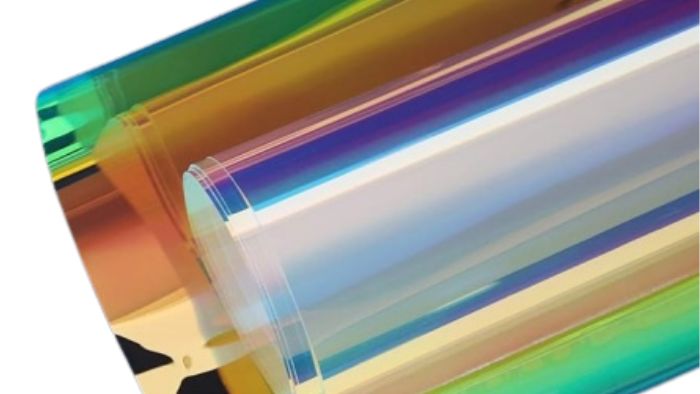

Shiny silver and clear or opaque film labels

Shiny silver films, as part of durable film labels, emulate the gleam of stainless steel, while clear and opaque options offer versatility with matte or glossy finishes. Glossy labels, in particular, provide a vibrant and polished appearance, enhancing color vibrancy and visual appeal.

These films endure harsh outdoor conditions and maintain shape, perfect for pipe and control panel labels. Widely applied in tool marking and air conditioning, they’re equipped with strong permanent adhesives for durability.

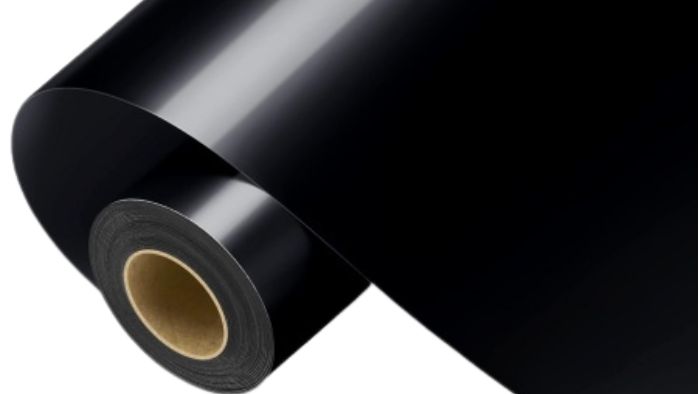

Vinyl labels

The top choice for outdoor labels, industrial vinyl boasts impressive UV fade resistance for 9-11 years, enduring harsh weather and chemicals. Various label adhesive types are used for vinyl labels, including general-purpose, aggressive, and removable adhesives. Its flexibility allows easy application over rivets and curved surfaces. Ideal for pipeline markings, fleet decals, tools, and more, ensuring long-lasting durability.

Unpeelable security Vinyl tamper evident labels

These tamper-evident labels resist removal in one piece, safeguarding proprietary products. Security labels reveal VOID, SECURITY, or DANGER when tampered with. Material selection varies based on surface. Widely used for food, pharmaceuticals, electronics, warranty, safety, and law enforcement seals.

As an equipment manufacturing company specializing in labeling pharmaceuticals, we have a number of tamper-evident labeling machines that make a range of contributions to pharmaceutical counterfeiting!

Electrostatic Vinyl

Electrostatic vinyl is ideal for crafting window decals without the need for adhesive, relying instead on static electricity for adherence. Typically used on glass, metal, and similar smooth surfaces, these labels are perfect for oil change reminders on windshields. They can be effectively printed using either laser or thermal transfer printers.

Versatile Polypropylene labels

Clear or white polypropylene labels serve as a vinyl alternative, boasting superior solvent resistance at a lower cost than polyester. BOPP labels, available in finishes such as silver, gold, white, and clear, offer excellent resistance to water and oil, making them suitable for a variety of applications. Available in glossy or matte finishes, polypropylene labels offer excellent flexibility and clarity. Adhesive selection depends on specific application requirements, ensuring optimal performance.

Our pharmaceutical labeling machines, such as syringe labeling machines and tube labeling machines, can use this type of label ……

Vibrant fluorescent and metallic foil

Fluorescent labels, available as vivid vinyl or synthetic materials, come in eye-catching colors like red, green, pink, and orange, making them perfect for safety warnings. These fluorescent labels are often used as safety labels for communicating warnings and important safety information. Foil labels, in shiny or matte silver or gold, also ensure visibility. Both types feature durable permanent adhesives for secure application.

Matte, semi-gloss, and high gloss label papers

Matte litho paper labels are uncoated and used primarily in sheet-fed laser printers or for computer pin-fed shipping labels. Different label adhesives, such as rubber-based and cold-temperature acrylic adhesives, are tailored for paper labels to suit various conditions and applications.

Labels for envelopes in office settings are often printed via direct thermal printers. They come with options for either permanent or removable adhesives.

Semi-gloss and high gloss papers use rubber-based or cold-temperature acrylic adhesives, the latter particularly suitable for food labeling. Removable adhesive options are available under specific conditions

Biodegradable materials

Biodegradable labels are crafted from materials that naturally decompose, making them an eco-friendly choice for companies prioritizing sustainability. These labels can be used in various environments and are particularly advantageous for disposable products, contributing significantly to waste reduction.

They are compatible with standard printing technologies and can be customized with water-based adhesives, ensuring both functionality and environmental responsibility.

Conclusion

This overview of label material showcases their crucial roles in communication and safety. From robust industrial vinyl to eco-friendly biodegradable options, each material is tailored to meet specific environmental and application demands, ensuring efficiency and sustainability in labeling practices.

Selecting the right label materials is essential for various applications, considering factors like performance, durability, and product design.