Pharmaceutical Carton Labeling Machines

Finding precise labeling solution for your cartons and boxes? Our labeling systems ensure clean and accurate label application on all box sizes and positions. Enhance your production line with our machinery.

- Works with different carton dimensions.

- Handles big labeling jobs easily.

- Accurate within ±1 mm.

- Fast delivery with full support.

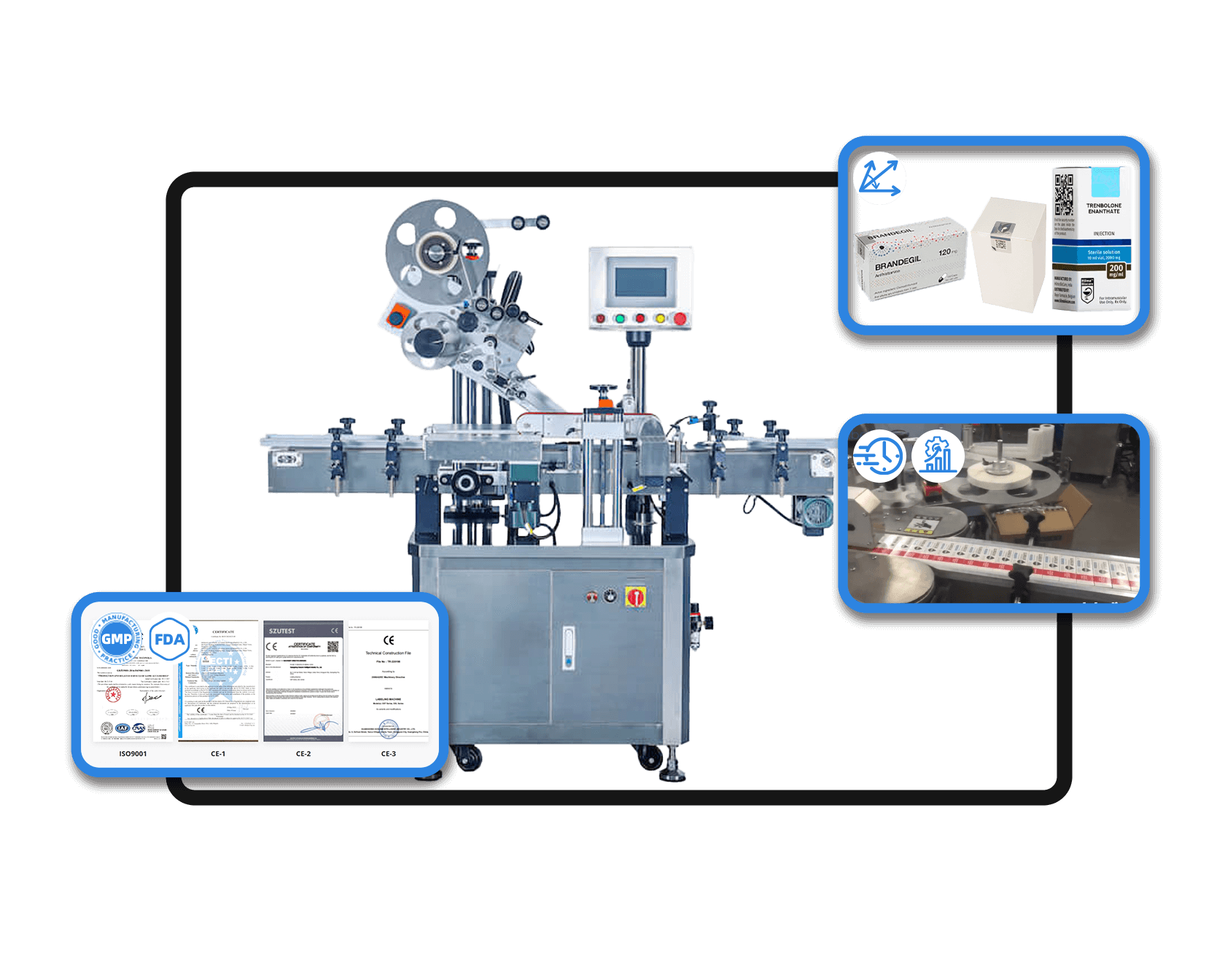

Featured Machinery

Our carton labeling systems are fully automatic. Help you speed up to labeling and reduce labor cost. Check machines below:

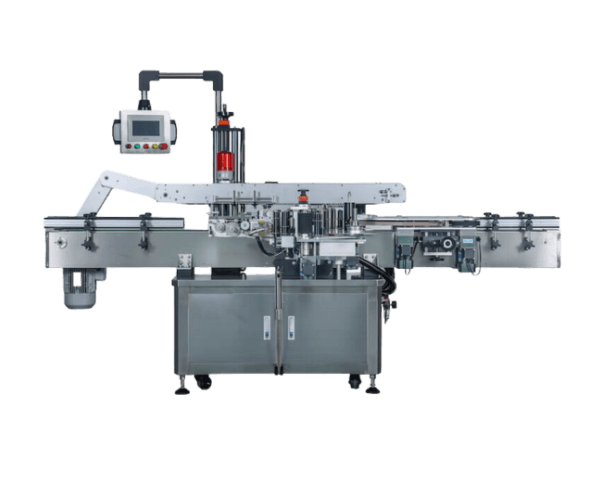

Pharma Carton Side Labeler Machine

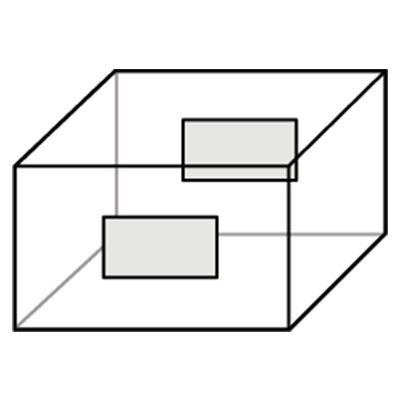

System type: side labeler, double side labeler, top side labeler

Applicable container types: cartons/boxes/bottles

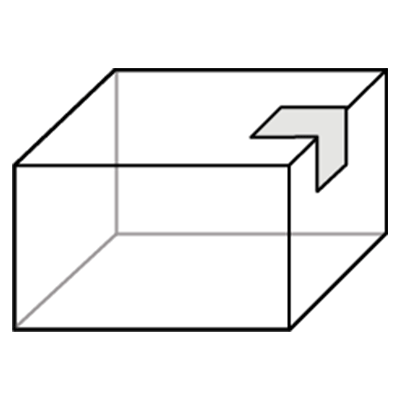

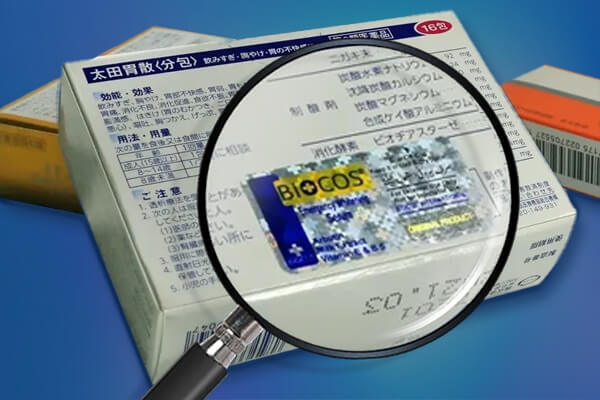

This machine helps the production line stay fast and accurate. And the equipment can also label the corners of carton boxes. This can add tamper-evident labels for anti-counterfeiting measures.

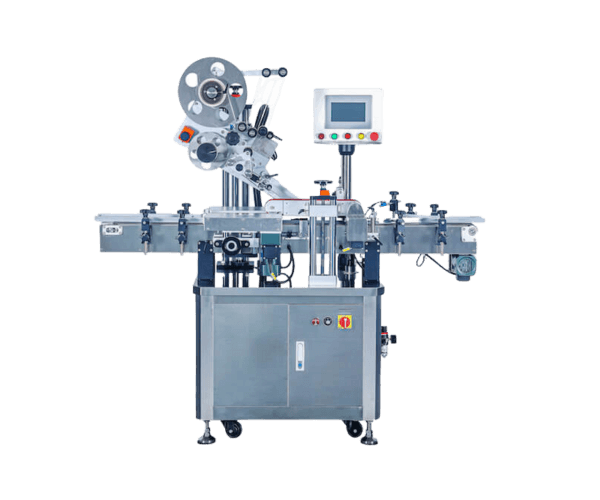

Pharma Small Box Labeler Machine

System type: Corner case labeler, anti-tamper labeler

Applicable box types: boxes(smaller cartons)

It can print and apply labels at the same time, making it more efficient in packaging operations.

Box Tamper Evident Labeling Machine

System type: Corner case labeler, anti-tamper labeler

Applicable box types: boxes(smaller cartons)

This labeling system is upgrade based on P-260. Equip with protect cover for human safety.

Why Choose Our Labeler Machine for Cartons Labeling?

Our labeler machines provide excellent solutions for carton labeling. They meet the varied needs of the pharmaceutical industry. We ensure precision and reliability. With advanced technology and strong support, we guarantee satisfaction and efficiency in every task.

Worldwide Countries Shipped

Years of Marketing Experience

Customer Satisfaction Guaranteed

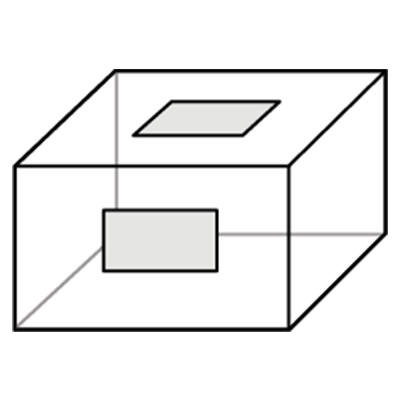

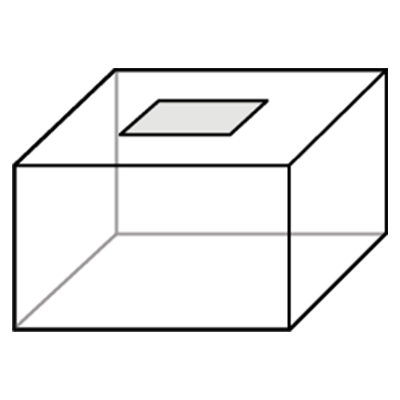

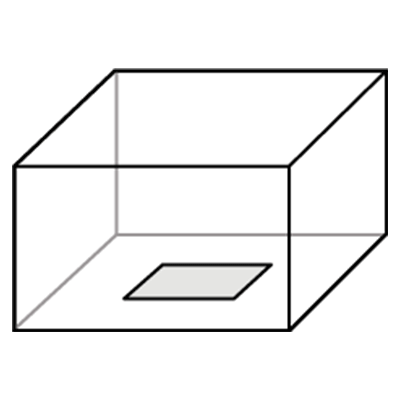

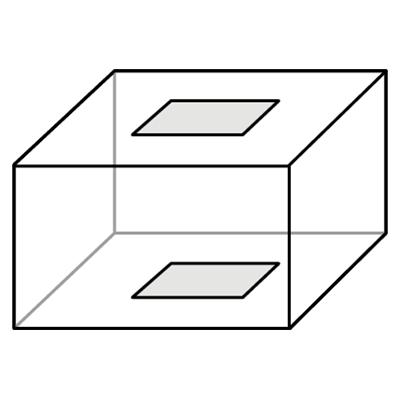

Labeling Machine Applications for Box Locations

VialLabeller labeling solutions can be configured to smoothly apply crisp, clean labels in cartons placements. And they work with folding cartons/boxes of all sizes.

Our carton labeling machines can label on these box position:

Machine Videos

See how we ensure precise label placement on these box/carton sizes when pharmaceutical manufacturing. The machines are user-friendly and work with various label types. They also integrate smoothly into existing production lines.

Labeling on box top side video

Labeling on packaging boxes corder video

Let’s work together

We’d love to hear from you! Send us a message using the form opposite, or email us. We’d love to hear from you! Send us a message using the form below.