Labeling machines serve many industries. Various types of labeling machines save time and cut costs for product information and marketing. They usually attach labels to products such as bottles, jars, and boxes.

Some machines operate by hand, while others operate based on automation. Choose the machine based on how many products need labeling. In this article, you will learn about the different labeling machines.

What is a labeling machine, and how does it operate?

It is a machine used to apply labels to various products, such as bottles, jars, and boxes.

A labeling machine enables businesses to use modern labeling technology. It applies labels to products without the need for manual application.

The machine rolls in labels and applies them to the product.

The product moves along the conveyor belt as it passes the labeling machine parts. Then, the machine places the label in the right position above it.

- Labeling machines are of different types. Some machines are completely automatic.

- They place labels on parts of products, such as the top, bottom, or sides, based on the machine and product type.

- It’s a quick and efficient way to prepare goods for sale.

Types of labeling machines by label application method

We classify labeling machines based on different criteria. Still, they will depend on the machine’s application procedure to the product surface. Below are some of the common types of labeling machines according to application:

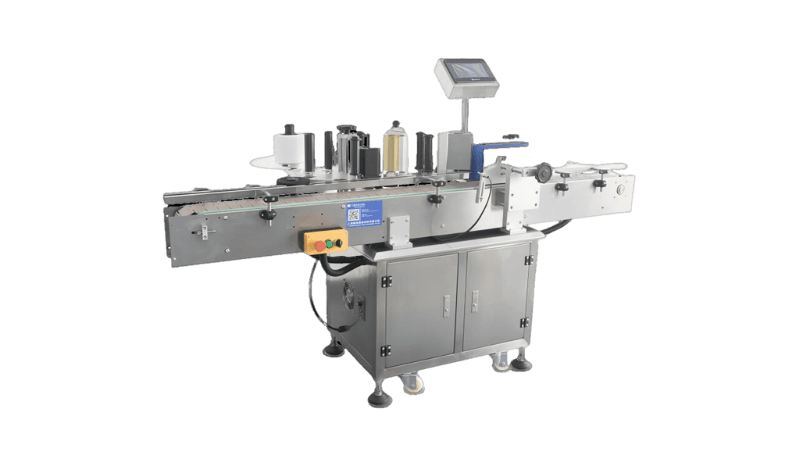

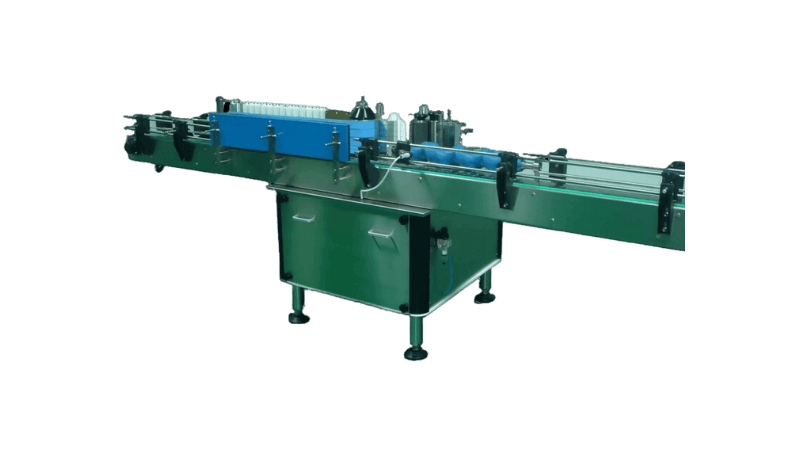

Side labeling machine

A side labeling machine puts labels on the sides of containers. It works well for things like boxes, jars, and bottles. The machine puts the label on one or both sides of the container.

This helps label things with flat or curved surfaces.

Side labeling machines are good for containers that are in a standing position. These machines make sure the label is neat and stuck on the side.

These machines help businesses label a large number of products very fast. They work and help speed up production. Side labeling machines can handle different shapes and sizes.

The machine can adjust to fit a tall or short container. This machine is often used for food, cosmetics, and medicine.

One great thing about side labeling machines is that they can label many sides at once. Some containers need labels on the front and back.

The machine can perform two operations at once, resulting in shorter durations. This is ideal for businesses that must label their products in large volumes.

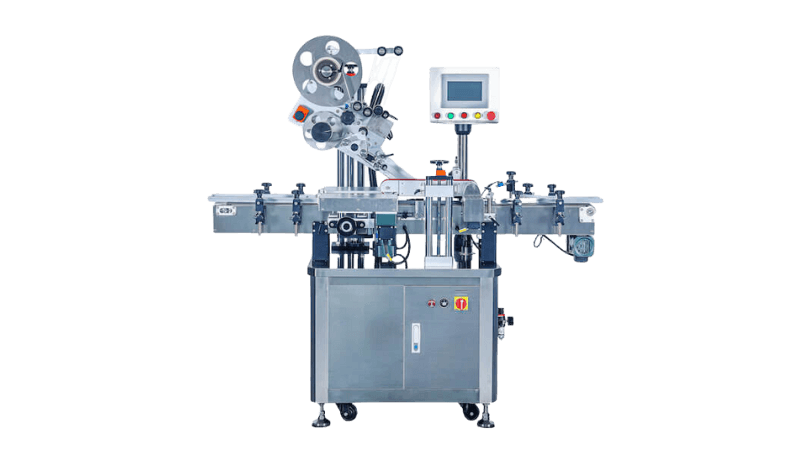

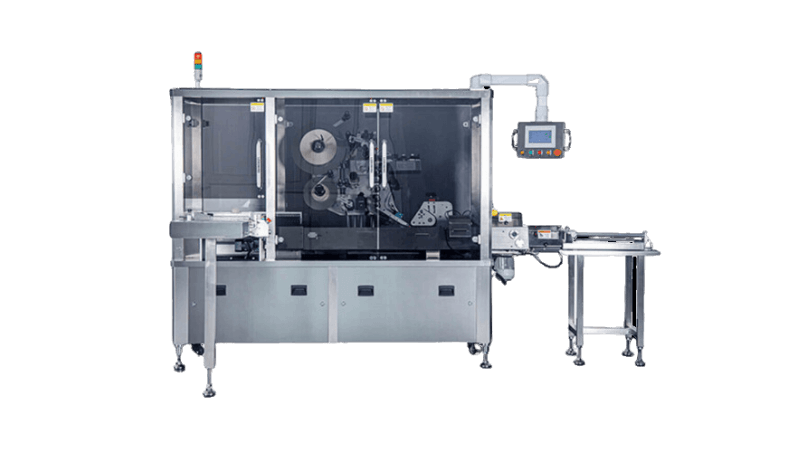

Multi-side labeling systems

Multi-side labeling systems are machines that put labels on more than one side of a container at once. This saves time because you don’t have to label each side at a time.

They’re helpful for products such as square or rectangular boxes or bottles that need labels. These machines can label all sides in one go, making everything faster. These machines work fast and can keep up with high-speed production lines.

They are great for factories or businesses that must label many products together. Labeling many sides at once makes the job easier and faster.

You can use them in many industries, especially where products need different labels. These machines apply labels for brand name, information, or safety all at once.

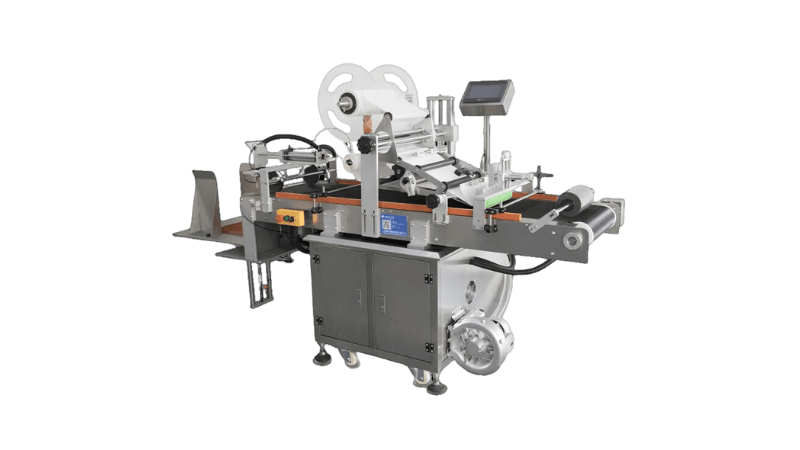

Top and bottom labeling machine

A top-and-bottom labeling machine puts labels on both the top and bottom of containers. This helps label products faster. These machines are being used for product boxes, jars, and other flat containers.

They put labels on both surfaces at once. Top and bottom labeling machines suit businesses producing large volumes. They work fast and are easy to set up, which helps production.

The machine puts the labels in the right place on both sides. This is important for products that need labels on the top and bottom.

These machines work in many sectors, including food, cosmetics, and packaging. For example, food jars or boxes need labels on the top and bottom.

The top and bottom labeling machines ensure that the labels stick straight away. They can also work with different product sizes and shapes.

Wrap-around labeling machine

A wraparound labeling machine labels round containers, like bottles and cans. The label wraps all around the container, covering it completely.

This machine is good for products like soda bottles and shampoo containers. It makes sure the label fits exactly and looks neat.

Wraparound labeling machines help convey a lot of information or branding. Industries such as beverages, cosmetics, and medicine use this machine.

For example, a soda company might want a label that wraps all around the bottle. The machine makes sure the label stays on tight and fits.

This machine works fast and is reliable. It can handle fast production lines, which helps businesses keep up with orders. It can also work with round containers of different sizes.

This makes it a great choice for industries that need to label many products all at once.

Corner wrap labeling machine

A corner wrap-around labeling machine puts labels on the corners of boxes or cartons. The label wraps around the corner, sticking to both sides. This is usually known as tamper-evident labeling.

It’s important for the safety of food and medicine.

Tamper-evident labeling helps customers know if a product has opened before. For example, food companies use this to prove the product is in perfect condition.

The pharmaceutical industry uses it to make sure the medicine is safe to use. The corner wrap labeling machine ensures the label stays firm in place and is hard to remove.

This machine provides extra security for packaging. It can label the corners of boxes or cartons.

The corner wrap machine makes sure the label sticks well and stays in place. It helps businesses keep their products safe and trusted.

Based on the running direction of the container

Here’s a simple explanation of labeling machines based on container movement:

Vertical labeling machine

Vertical labeling machines apply labels to containers that stay upright.

- It applies the label straight from the top or sides concerned and is ideal for round or flat containers.

- It is perfect for round bottles, jars, or cans.

- Labels are usually applied to products such as water bottles and cosmetics.

- Good application for products requiring labels on one or more sides.

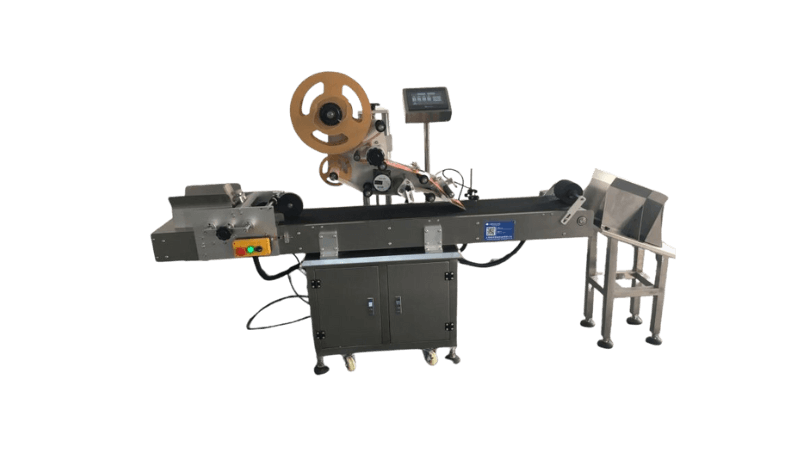

Horizontal labeling machine

A horizontal machine labels products that lie horizontally. You can use this in factories for food and similar items requiring labels.

- Flat items on a conveyor belt are moved along as a machine traverses over them.

- The machine sticks labels on the items as they go by.

- Works quickly and ensures accurate placement of labels.

- Works with products of different cylindrical shapes and sizes

- It does the job without people having to do much.

Based on the degree of control

Labeling machines are usually sorted into semi-automatic, and automated categories. Each of these machines provides a different speed, control, and convenience level.

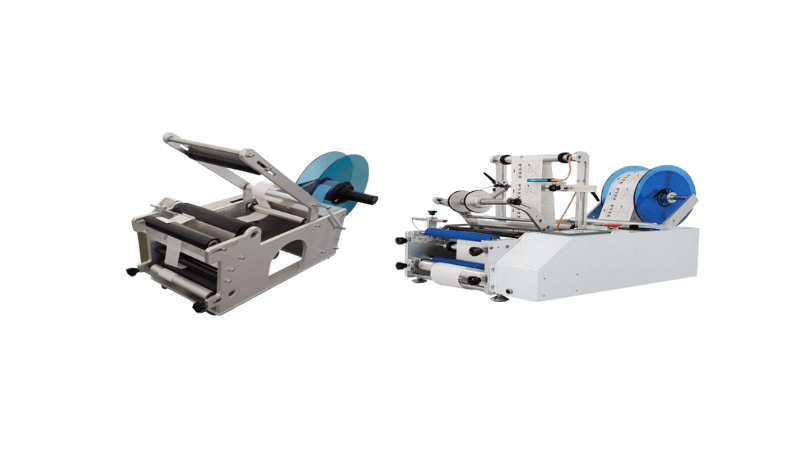

Semi-automatic labeling machine

Semi-automatic labeling machines include both manual and semi-automatic operations.

These machines need operators to position products and apply labels but work faster than manual ones. These machines are suitable for small to medium-sized businesses.

- Operators position the container, and the machine applies the label.

- Ideal for businesses handling a moderate number of products.

- Inexpensive, portable, and easy to use.

- Works well for small goods, crafts, and midsized labeling tasks.

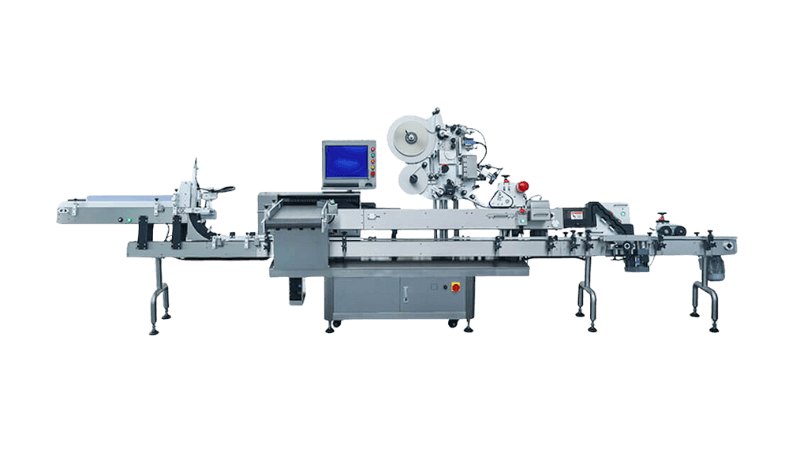

Automatic labeling machine

Automatic labeling machine operate on itself, requiring minimal input from the operator.

- These machines are best for wider production purposes.

- It requires high-speed production with little human labor.

- Fast and efficient for demanding production purposes.

- Not requiring much human involvement.

Based on the type of label

Labeling machines are being classified based on the label type they use. The label’s use depends on the product and material involved.

Self-adhesive (pressure-sensitive) labeling machine

This self-adhesive labeling machine uses pre-glued labels, which makes it faster and cleaner. The roll-fed labels do not need water or heat to attach.

- It uses pre-glued labels that don’t need water or heat.

- Fast and effective for medium- to high-speed labeling.

- Works for soft packages and rigid containers.

- Labels can be shaped or designed in various ways.

- There is no risk of damage from heat or water.

Shrink sleeve labeling machine

You can use this machine to apply plastic sleeves around a container. On heating, it shrinks around the container.

This is usually applied to products such as carbonated soft drinks or cosmetics. A neat heat-shrunk label not only gives the product a neat look but also makes it stand out.

- Shrink sleeve labels shrink around containers by applying heat.

- They fit on any type of shape, including odd or curved ones.

Hot melt labeling machine

It uses glue in solid form at room temperature but melts upon heating. It applies labels onto products, such as bottles, by wrapping them around.

This machine provides glue with a precise application, ensuring labels are properly attached.

- It uses glue that melts when heated and sticks to products.

- Great for wrap-around labels in bottles and jars.

- Provides a tight, neat fit for labels.

- Applications are for high-precision labeling.

- Best suited to larger containers or products that need full-body labeling.

Cold glue labeling machine

This machine uses a liquid adhesive that sticks labels onto products. It is also used to attach labels to cans. It is ideal for high-speed labeling.

You can use this in the bottling system to label beverages that must be fast and quick. This works on both glass and plastic bottles and in decorating labels that can be shaped.

- It uses liquid adhesive to attach labels.

- Best suited for application of paper labels on bottle, jar, and can applications.

- Compatible with glass or plastic containers.

- Capable of applying fancy, embossed, or shaped labels.

Conclusion

The types of labeling machines you choose depend on what you are labeling and how many items need labels.

Whether you make small amounts or large batches, there’s always a machine to help you work faster and better.

Learning about different labeling machines and how they work can help you pick the best one. If you need a simple manual machine, having the right machine will make labeling easier.

For pharmaceutical firms, VialLabeller provides automation systems with the best precision for labeling. These machines guarantee precision, efficiency, and complete compliance with industry regulations.

Contact us now for details to find the right solution for your pharma labeling needs.

FAQs

Which labeling machine is appropriate for small businesses?

The best label maker machine for small businesses is easy to use and affordable to buy. A labeling machine handling small batches of labels quicker will keep costs lower.

Which is the best label maker for home use?

The best home-use label maker is compact, simple, and provides clear labels. Finding a label-making machine to print labels and organize stuff would be great.

What sort of labeling machines are being used in factories?

In factories, an industrial label maker is often used to handle high-volume labeling. These labeling machines work fast. They label large numbers of products, often on production lines.