The process of medical device manufacturing is pivotal in ensuring the delivery of safe and effective healthcare solutions. From the initial concept to the final product reaching the shelves, each phase in the production of medical devices is critical.

Additive manufacturing is a key technology in medical device manufacturing, offering innovative solutions for creating high-performance medical devices and implants.

This comprehensive overview outlines the essential steps in the creation of medical equipment, highlighting the importance of each stage in meeting industry standards and ensuring patient safety.

Market research and product design for medical devices

Market needs analysis: Understanding the demands and requirements of the healthcare sector is the first step. This involves identifying gaps in the market and the specific needs of healthcare providers and patients, allowing for the design and development of a broad range of products.

Design and planning: Based on the market analysis, medical devices are designed with precision to meet stringent health standards. Initial designs are adjusted through iterations to ensure functionality, user-friendliness, and compliance with medical regulations.

Product development

Technical development: Engineers and developers work to create the technologies and processes required to produce the medical device. This often involves groundbreaking work in fields such as biomechanics, electronics, and materials science. The choice of manufacturing processes, such as sheet metal fabrication and welding, is crucial as it impacts the strength, cost efficiency, and ability to produce complex parts required for functional medical devices.

Prototype manufacturing: Prototypes are essential for visualizing the design and functionality of the device. These initial models undergo rigorous testing to ensure they perform as intended.

Clinical trials

- Trial design: Clinical trials must be meticulously planned to comply with medical ethical standards and scientific validity. They must secure approval from regulatory bodies before commencing.

- Implementation: Trials are conducted with patient volunteers to collect data on the efficacy and safety of the medical device, often conducted across various demographics and conditions.

Registration and approval in regulatory affairs

- Documentation: Compiling all necessary documentation, including clinical trial reports and product specifications, is crucial for submission.

- Regulatory submission: The comprehensive dossier is submitted to health authorities to obtain the necessary approvals to bring the device to market.

Production preparation

- Facility construction: Production facilities must be constructed or adapted to suit the manufacturing needs of the new medical device, ensuring compliance with production standards.

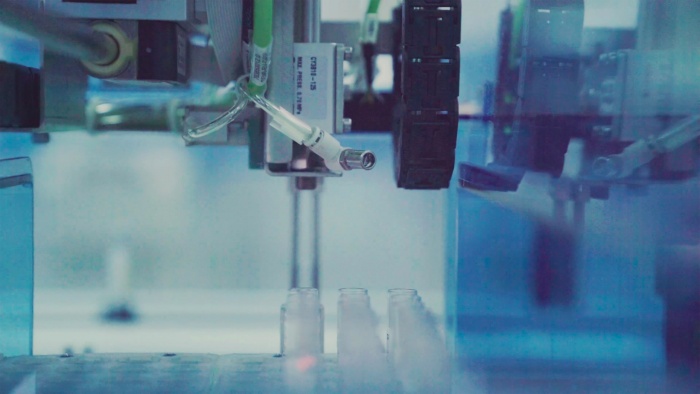

- Production line setup: Assembly lines are set up with the necessary equipment and configured to maximize efficiency while maintaining product quality. The use of injection-molded plastic parts is crucial in this setup due to their durability, cleanliness, and adaptability to hostile bodily fluids, making them ideal for high-volume production of medical devices.

Manufacturing execution and processes

- Material procurement: Sourcing high-quality materials that meet medical-grade standards is essential for production.

- Manufacturing: The manufacturing process involves strict adherence to the production protocols to ensure each device is built to specifications. This includes the production of implantable medical devices, which play a crucial role in managing advanced heart disease by controlling heart rhythm and supporting overall heart function.

Quality assurance

- Standard development: Establishing strict quality standards to inspect each device ensures that they function correctly and are safe for use.

- Product testing: Devices undergo a series of tests to validate their performance and safety under various conditions.

Labeling and packaging

- Labeling: Proper pharmaceutical labeling is crucial in medical device manufacturing. Each device receives labels that provide essential information, such as usage instructions, batch numbers, and regulatory compliance marks.

- Packaging: Devices are then packaged in a manner that ensures their integrity and sterility until they reach the end-user.

Why medical device manufacturing is crucial

Medical device manufacturing plays a pivotal role in healthcare. These devices, ranging from simple thermometers to complex surgical instruments, are essential for diagnosing diseases, monitoring patient health, and providing effective treatments.

From diagnostic imaging equipment to implantable devices, medical devices contribute significantly to improving patient outcomes and quality of life. Additionally, advancements in medical technologies lead to earlier disease detection and more effective treatments, further enhancing overall health outcomes.

Conclusion

Medical device manufacturing involves a complex series of steps, each crucial to ensuring that the final products are both effective and safe.

The journey from conception to market involves rigorous testing, quality control, and compliance with strict regulatory standards. Understanding these processes is essential for anyone involved in the production of medical devices. Effective regulatory affairs practices are vital in ensuring the safety and efficacy of medical devices.

Our labeling machine can participate in an important part of this. Whether it is vials or syringes, Viallabeller’s machines can provide you with the ideal labeling solution.

In addition to these two products, we also provide solutions for the following medical products: