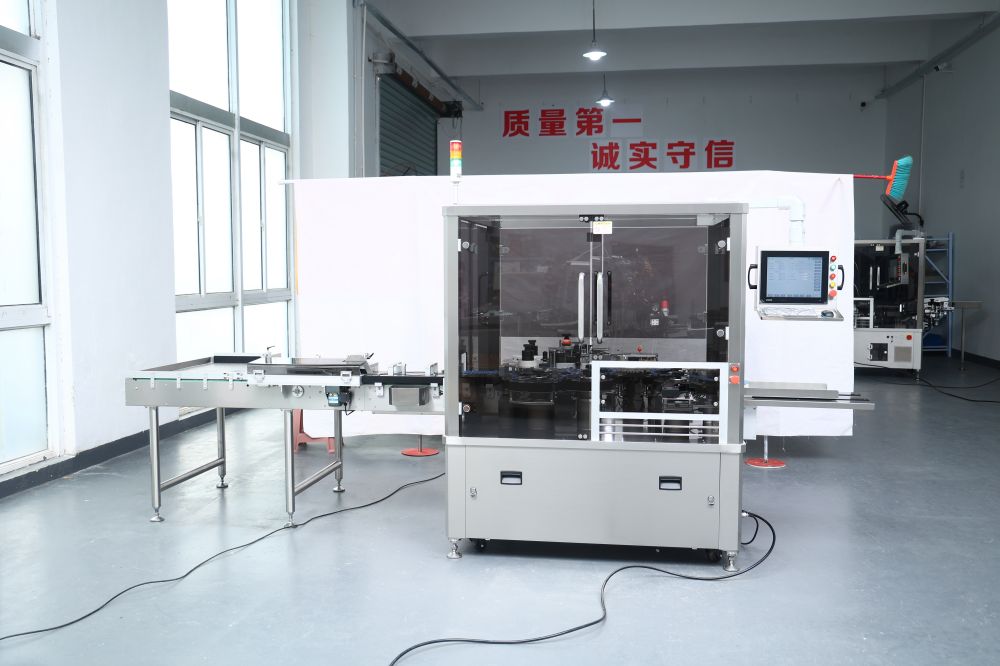

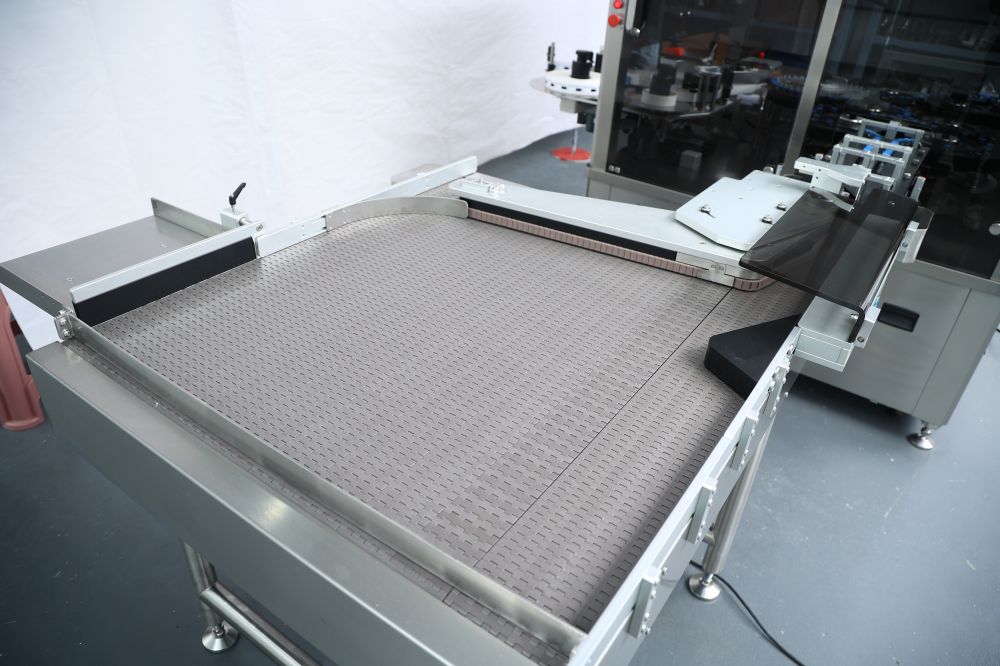

Y-700 Labeling Machine

Y-700 Rotary Vertical Labeling Machine

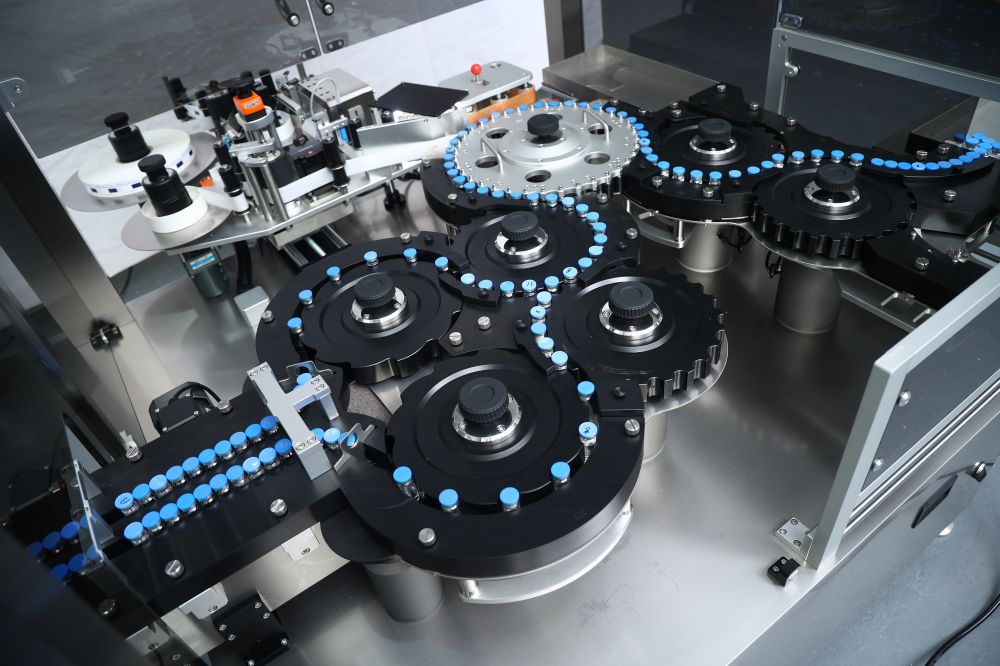

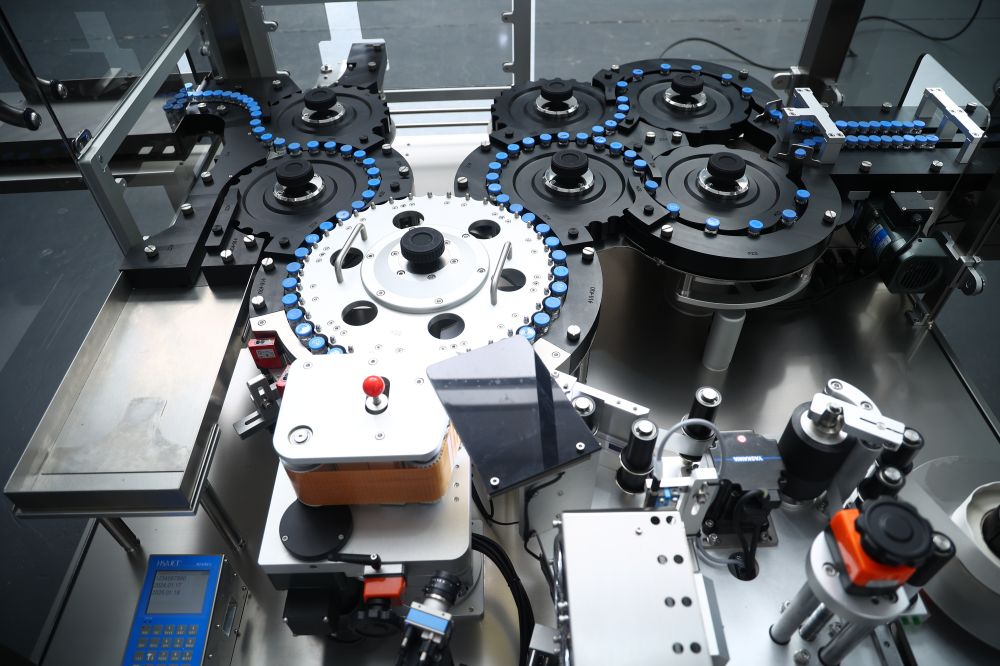

1. Precision Vertical Labeling for Round Bottles: Elevate your labeling efficiency with the Y-700 Rotary Vertical Labeling Machine. This machine is designed for vertical labeling on round bottles, including vials and syrup bottles of various specifications, ensuring precise label placement with an accuracy of ±0.5mm. The star wheel mechanism efficiently rejects unqualified products using positive pressure suction, ensuring stable operation and simplifying maintenance.

2. Robust Three-Stage Labeling Head: The Y-700 features a three-stage labeling head with feed, drag, and paper collection devices, each controlled by an independent motor for fast and stable label transmission. Achieving a maximum label out-feed speed of 95 m/min, this machine guarantees high-speed labeling accuracy. The dual-channel feeding technology replaces the traditional bottle-dividing screw auger, improving feeding efficiency and making format changes faster and more convenient.

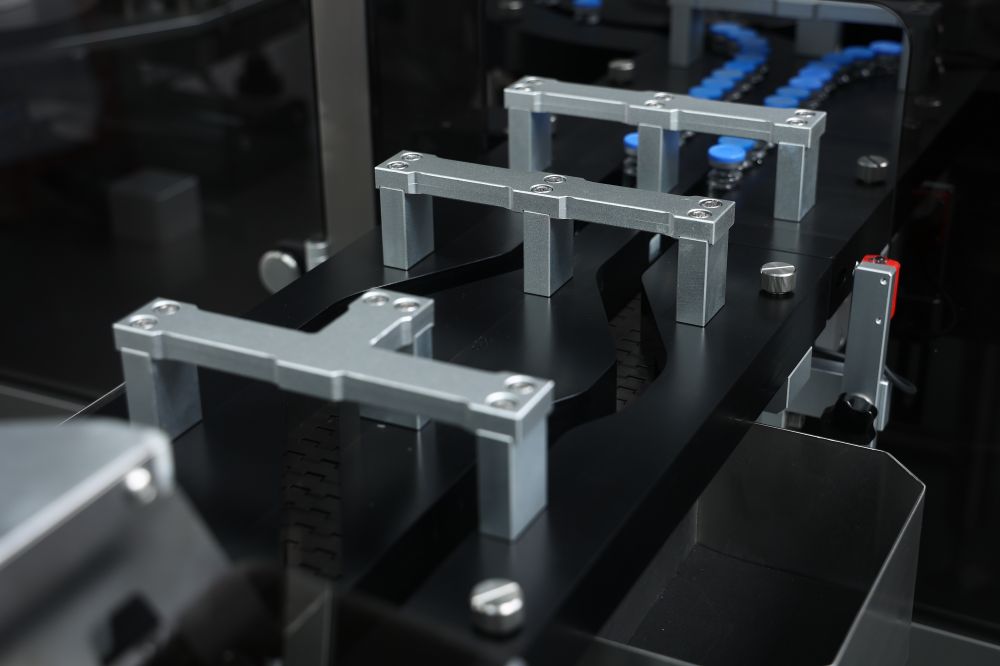

3. User-Friendly and Durable Design: The gear’s anti-backlash technology ensures transmission accuracy and long-term stability. Quick format changes are made easy by locating pins on change parts, eliminating the need for positional adjustments. The openable spoke wheel device with a synchronous belt and spring buffering ensures smooth and durable operation, reducing the risk of bottle breakage. The touchscreen interface simplifies operation, displaying abnormalities and guiding troubleshooting, while the recipe selection and saving functions enhance efficiency. Optional software with an audit trail and electronic signature is available to meet FDA 21 CFR Part 11 requirements.

| Machine Parameters | |

| Applicable bottle diameter | 16-42.5mm |

| Applicable label material | Paper labels and transparent labels |

| Labeling speed | 0-700 bottles /min |

| Labeling accuracy | ±1mm ( except packaging material error ) |

| Product broken rate | < 0.01 % |

| Label breakage rate | < 0.1 % |

| Labeling pass rate | > 99.9% |

| Power supply | 5KW, AC220V, 50HZ |

| Air consumption | 0.6Mpa,500L /min |

| Machine dimension | 3508*1873*2109mm |

| Total weight (approximately) | Around 500Kg |

| Noise | <75dB ( one meter away from the equipment ) |

| Applicable inner diameter of the label roll | φ76mm |

| Maximum Label Roll Outer Diameter | Φ400mm |

| Self-adhesive label parameters | |

| Label spacing | 2-4 mm |

| Top/bottom margins on liner | 2 mm |

| Grammage | >62 g/m2 |

| Thickness | >55 μm |

| Tensile strength | Machine Direction : 16kg/25mm ,Cross direction: 7kg/25mm |

| Breaking strength | Machine Direction : 25g/sheet ,Cross direction: 31g/sheet |

| Transparency | 0.52 |