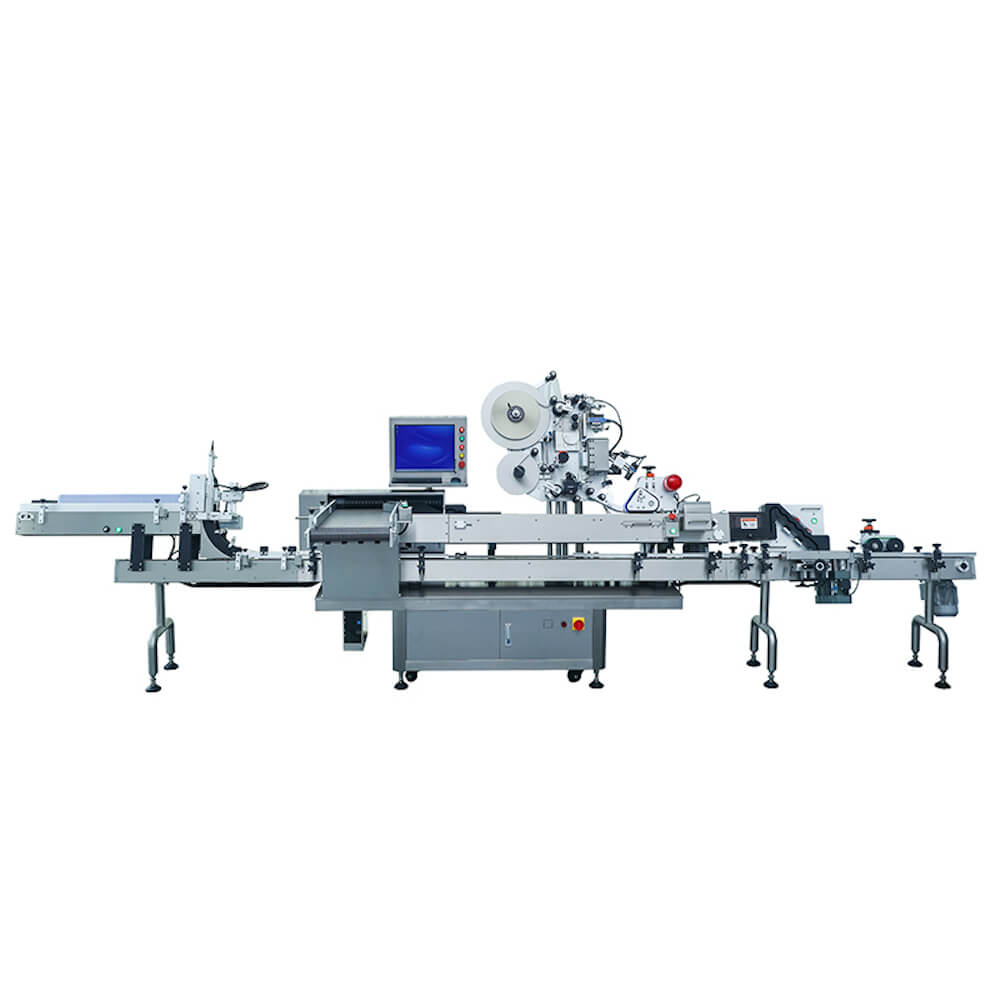

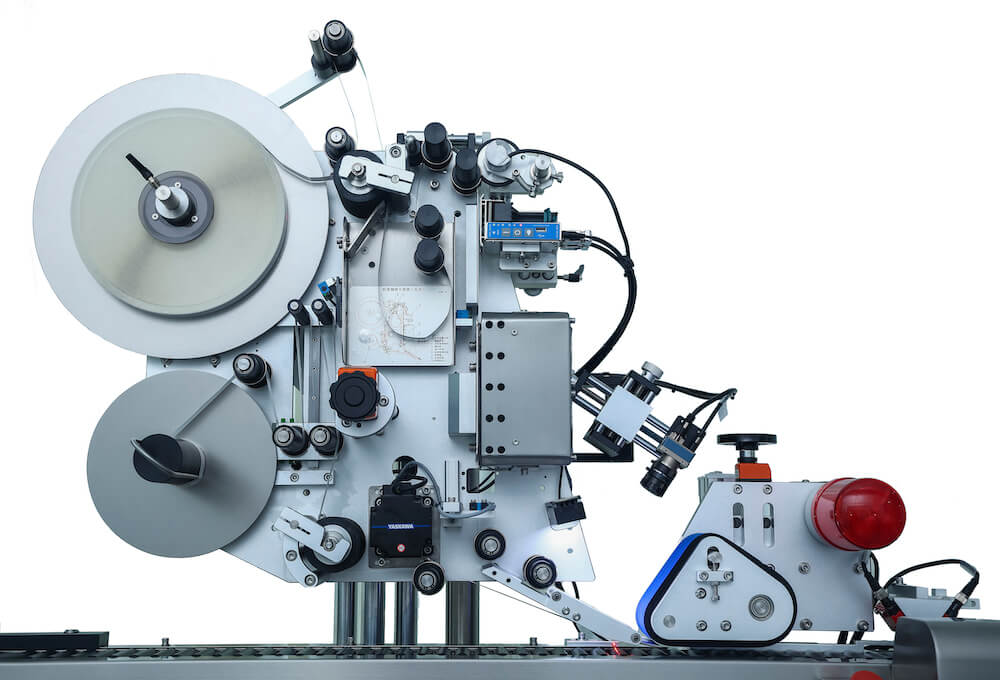

Y-510 Labeling Machine

Y-510 Automatic tray inserting and ampoule bottles labeling machine

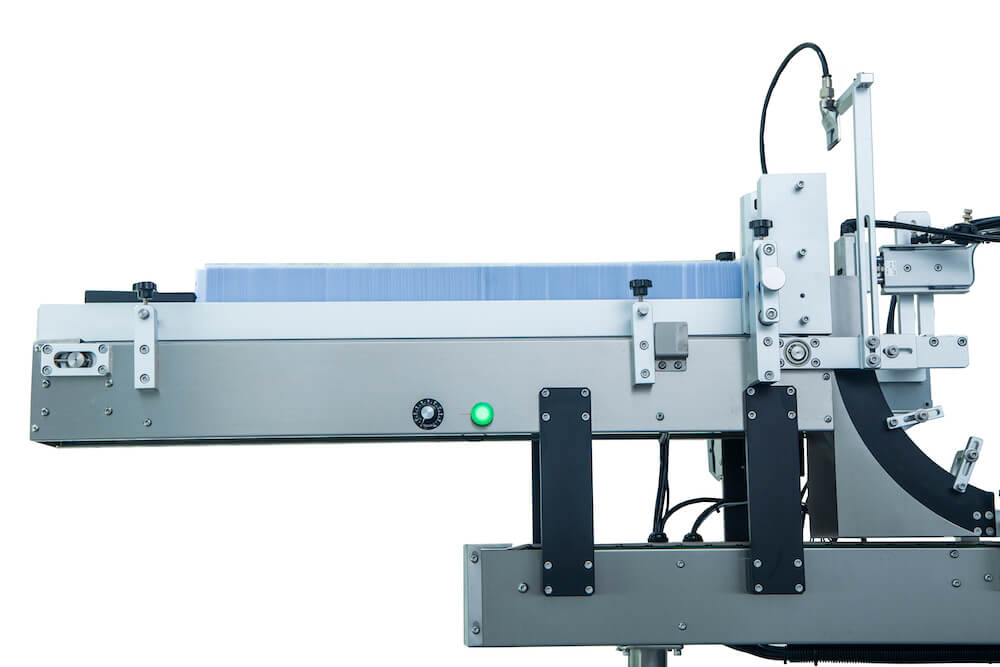

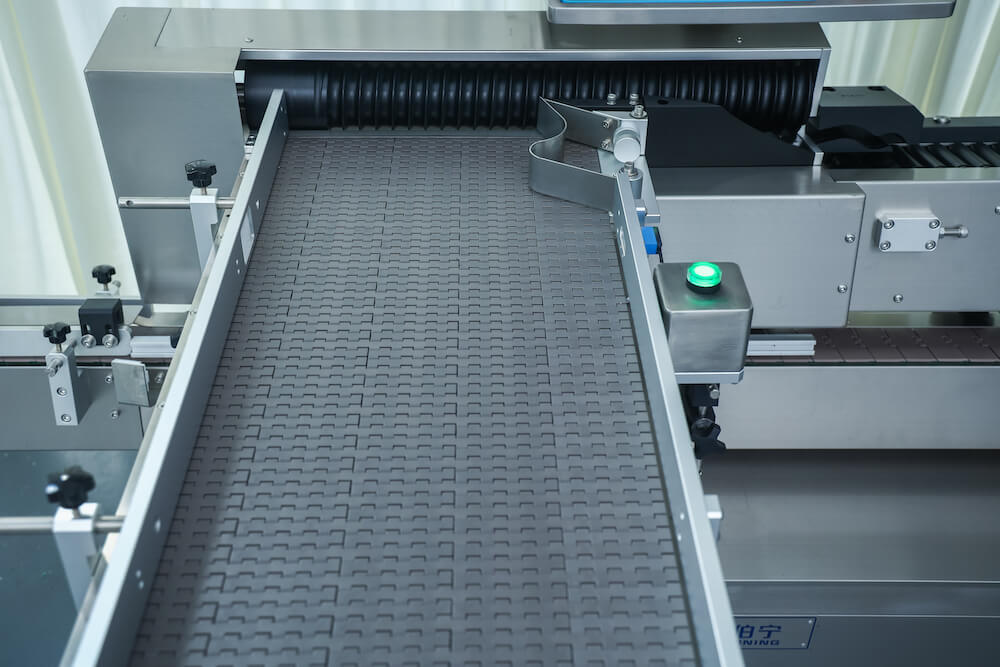

1. Efficient Tray Inserting System: The Y-510 Automatic Machine excels with its tray inserting system, designed specifically for 1-20ml ampoules. It can handle trays ranging from 50-150mm in length and 60-120mm in width, accommodating either 5 or 10 ampoules per tray. With a capacity of 30 to 90 trays per minute, it ensures swift and efficient packaging, essential for high-throughput pharmaceutical environments.

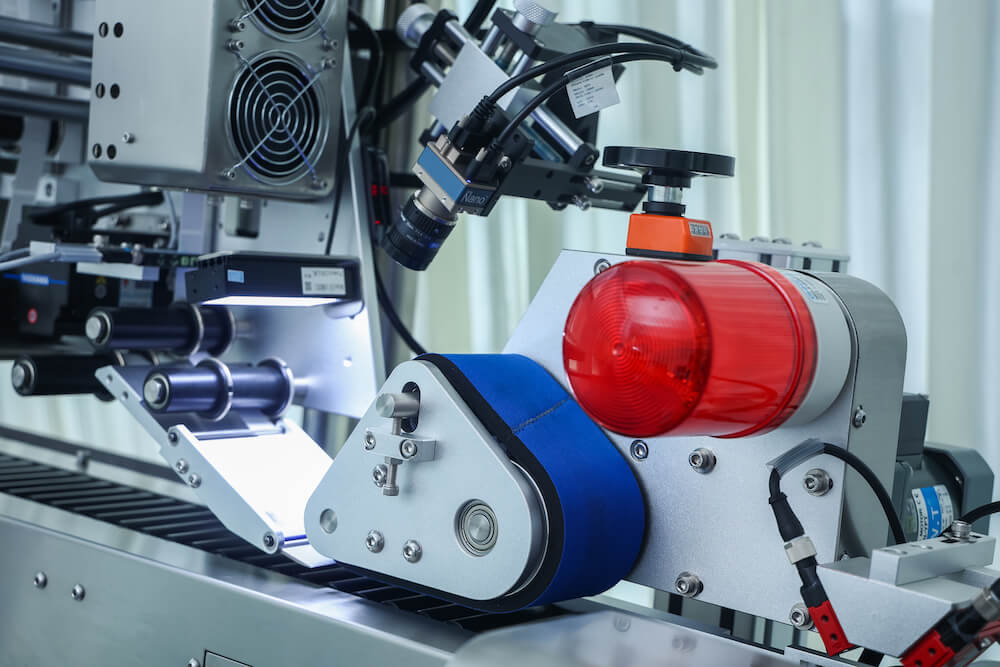

2. High-Speed, Accurate Labeling Functionality: This machine is not just a tray inserter but also a proficient labeler for ampoule bottles sized 10-30mm. It offers a remarkable labeling speed of up to 500 bottles per minute with a precision of ±1mm. Its compatibility with both paper and transparent labels, along with a high labeling pass rate of over 99.9%, ensures it meets diverse labeling needs with exceptional accuracy.

3. Robust Design with User Safety in Mind: The Y-510 is designed for durability and ease of use, requiring 0.4kw power and operating below 75dB noise level for a comfortable working environment. It supports PVC trays with specific dimensional requirements for uniformity, ensuring smooth and consistent operation. The machine’s robust build, with a total weight of approximately 380Kg, and capacity to handle label rolls up to Φ300mm in diameter, make it a versatile and reliable choice for automated pharmaceutical packaging.

Technical Parameters

Tray Inserting System Parameters

| Applicable Products | 1-20ml ampoules,5pcs/tray or 10pcs/tray |

| Applicable tray size | Length:50-150mm,Width:60-120mm |

| Tray inserting capacity | 30~90trays/min |

| Airsource | 0.4MPa |

| Air Consumption | 300 L/min(90 trays/min) |

| Power | 0.4kw |

| Request of PVC trays | 1.The edges of the plastic tray need to be neat and uniform in size. 2.The width dimensions of the edges of the plastic tray should be 3.5mm at least. 3.The thickness of the plastic tray should be large than 0.30mm.” |

Labeling System Parameters

| Applicable product size | 10-30mm |

| Applicable label material | Paper labels and transparent labels |

| Labeling speed | 0-500 bottles /min |

| Labeling accuracy | ±1mm ( except packaging material error ) |

| Length of label | 25-95mm |

| Product broken rate | < 0.01 % |

| Label breakage rate | < 0.1 % |

| Labeling pass rate | > 99.9% |

| Power supply | 2.5KW, AC220V, 50HZ |

| Wire Specifications | >1.5mm² |

| Total weight (approximately) | Around 380Kg |

| Noise | <75dB ( one meter away from the equipment ) |

| Applicable inner diameter of the label roll | φ76mm |

| Maximum Label Roll Outer Diameter | Φ300mm |

Self-adhesive label parameters

| Label spacing | 2-4 mm |

| Top/bottom margins on liner | 2 mm |

| Grammage | >62 g/m2 |

| Thickness | >55 μm |

| Tensile strength | Machine Direction : 16kg/25mm ,Cross direction: 7kg/25mm |

| Breaking strength | Machine Direction : 25g/sheet ,Cross direction: 31g/sheet |

| Transparency | 0.52 |